- Home

- Products

- Tool Holder for Machining Center

- Milling Chuck

- MLD Multi-Lock Milling Chuck

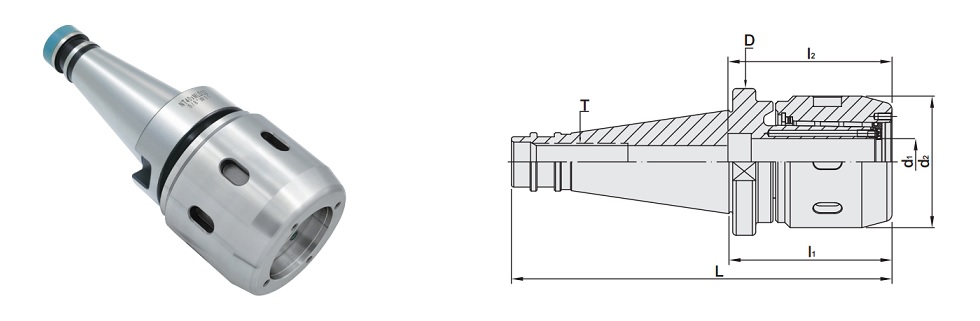

MLD Multi-Lock Milling Chuck

series:

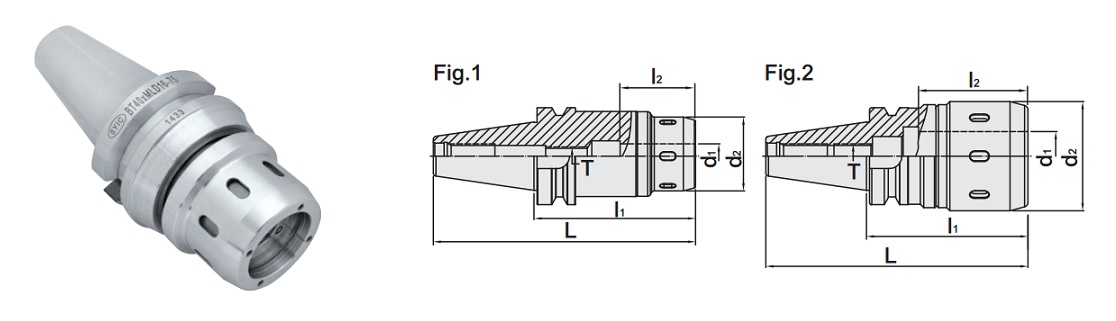

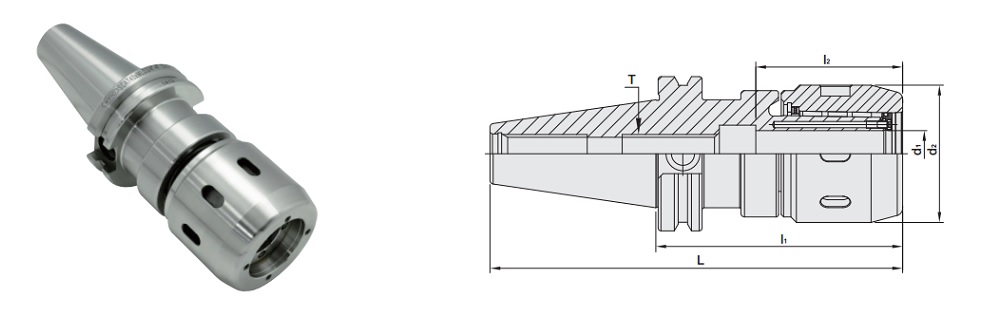

BT/MLD MULTI-LOCK MILLING CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | T | Fig. | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|

| 5010-460-012-080 | BT30xMLD12-80 | 128.4 | 80 | 46.7 | 12 | 42 | M10 x 1.5P | 2 | 1.00 |

| 5010-460-016-075 | BT30xMLD16-75 | 123.4 | 75 | 56.7 | 16 | 48 | M12 x 1.75P | 1 | 1.20 |

| 5010-460-020-080 | BT30xMLD20-80 | 128.4 | 80 | 59.3 | 20 | 56.5 | M12 x 1.75P | 2 | 1.90 |

| 5010-460-020-090 | BT30xMLD20-90 | 138.4 | 90 | 59.3 | 20 | 56.5 | M16 x 2.0P | 2 | 2.00 |

| 5010-460-025-090 | BT30xMLD25-90 | 138.4 | 90 | 58.2 | 25 | 60 | M16 x 2.0P | 2 | 1.80 |

| 5011-460-012-075 | BT40xMLD12-75 | 140.4 | 75 | 46.7 | 12 | 42 | M12 x 1.75P | 1 | 1.50 |

| 5011-460-012-105 | BT40xMLD12-105 | 170.4 | 105 | 46.7 | 12 | 42 | M12 x 1.75P | 1 | 2.00 |

| 5011-460-012-135 | BT40xMLD12-135 | 200.4 | 135 | 46.7 | 12 | 42 | M12 x 1.75P | 1 | 2.10 |

| 5011-460-016-075 | BT40xMLD16-75 | 140.4 | 75 | 56.7 | 16 | 48 | M12 x 1.75P | 1 | 1.70 |

| 5011-460-016-105 | BT40xMLD16-105 | 170.4 | 105 | 56.7 | 16 | 48 | M12 x 1.75P | 1 | 2.30 |

| 5011-460-016-135 | BT40xMLD16-135 | 200.4 | 135 | 56.7 | 16 | 48 | M12 x 1.75P | 1 | 2.40 |

| 5011-460-020-080 | BT40xMLD20-80 | 145.4 | 80 | 59.3 | 20 | 56.5 | M16 x 2.0P | 1 | 2.30 |

| 5011-460-020-100 | BT40xMLD20-100 | 165.4 | 100 | 59.3 | 20 | 56.5 | M16 x 2.0P | 1 | 2.50 |

| 5011-460-020-135 | BT40xMLD20-135 | 200.4 | 135 | 59.3 | 20 | 56.5 | M16 x 2.0P | 1 | 2.80 |

| 5011-460-025-085 | BT40xMLD25-85 | 150.4 | 85 | 58.2 | 25 | 60 | M16 x 2.0P | 1 | 2.20 |

| 5011-460-025-100 | BT40xMLD25-100 | 165.4 | 100 | 58.2 | 25 | 60 | M16 x 2.0P | 1 | 2.40 |

| 5011-460-032-095 | BT40xMLD32-95 | 160.4 | 95 | 71.7 | 32 | 71 | M16 x 2.0P | 2 | 2.70 |

| 5011-460-032-105 | BT40xMLD32-105 | 170.4 | 105 | 71.7 | 32 | 71 | M16 x 2.0P | 2 | 2.70 |

| 5011-460-032-135 | BT40xMLD32-135 | 200.4 | 135 | 71.7 | 32 | 71 | M16 x 2.0P | 2 | 3.00 |

| 5012-460-012-105 | BT50xMLD12-105 | 206.8 | 105 | 46.7 | 12 | 42 | M12 x 1.75P | 1 | 4.60 |

| 5012-460-012-135 | BT50xMLD12-135 | 236.8 | 135 | 46.7 | 12 | 42 | M12 x 1.75P | 1 | 5.10 |

| 5012-460-012-165 | BT50xMLD12-165 | 266.8 | 165 | 46.7 | 12 | 42 | M12 x 1.75P | 1 | 5.80 |

| 5012-460-016-105 | BT50xMLD16-105 | 206.8 | 105 | 56.7 | 16 | 48 | M12 x 1.75P | 1 | 4.90 |

| 5012-460-016-135 | BT50xMLD16-135 | 236.8 | 135 | 56.7 | 16 | 48 | M12 x 1.75P | 1 | 5.60 |

| 5012-460-016-165 | BT50xMLD16-165 | 266.8 | 165 | 56.7 | 16 | 48 | M12 x 1.75P | 1 | 6.50 |

| 5012-460-020-105 | BT50xMLD20-105 | 206.8 | 105 | 59.3 | 20 | 56.5 | M16 x 2.0P | 1 | 4.50 |

| 5012-460-020-150 | BT50xMLD20-150 | 251.8 | 150 | 59.3 | 20 | 56.5 | M16 x 2.0P | 1 | 4.90 |

| 5012-460-025-100 | BT50xMLD25-100 | 201.8 | 100 | 58.2 | 25 | 60 | M16 x 2.0P | 1 | 4.80 |

| 5012-460-025-130 | BT50xMLD25-130 | 231.8 | 130 | 58.2 | 25 | 60 | M16 x 2.0P | 1 | 5.70 |

| 5012-460-032-105 | BT50xMLD32-105 | 206.8 | 105 | 71.7 | 32 | 71 | M24 x 3.0P | 1 | 5.00 |

| 5012-460-032-135 | BT50xMLD32-135 | 236.8 | 135 | 71.7 | 32 | 71 | M24 x 3.0P | 1 | 5.20 |

| 5012-460-032-165 | BT50xMLD32-165 | 266.8 | 165 | 71.7 | 32 | 71 | M24 x 3.0P | 1 | 6.70 |

| 5012-460-042-115 | BT50xMLD42-115 | 216.8 | 115 | 84.8 | 42 | 90 | M24 x 3.0P | 1 | 5.50 |

| 5012-460-042-130 | BT50xMLD42-130 | 231.8 | 130 | 84.8 | 42 | 90 | M24 x 3.0P | 1 | 6.50 |

| 5012-460-042-165 | BT50xMLD42-165 | 266.8 | 165 | 84.8 | 42 | 90 | M24 x 3.0P | 1 | 7.70 |

| 5010-460-A32-315 | BT30xMLD1/2"-3.15" | 5.05 | 3.15 | 1.84 | 0.5 | 1.654 | M12 x 1.75P | 2 | 1.00 |

| 5010-460-A40-295 | BT30xMLD5/8"-2.95" | 4.86 | 2.95 | 2.23 | 0.625 | 1.889 | M12 x 1.75P | 1 | 1.20 |

| 5010-460-A48-354 | BT30xMLD3/4"-3.54" | 5.449 | 3.54 | 2.34 | 0.75 | 2.224 | M12 x 1.75P | 2 | 1.90 |

| 5010-460-A64-354 | BT30xMLD1"-3.54" | 5.449 | 3.54 | 2.49 | 1 | 2.362 | M16 x 2.0P | 2 | 1.80 |

| 5011-460-A32-295 | BT40xMLD1/2"-2.95" | 5.528 | 2.95 | 1.84 | 0.5 | 1.654 | M12 x 1.75P | 1 | 1.50 |

| 5011-460-A40-295 | BT40xMLD5/8"-2.95" | 5.528 | 2.95 | 2.23 | 0.625 | 1.889 | M12 x 1.75P | 1 | 1.70 |

| 5011-460-A48-315 | BT40xMLD3/4"-3.15" | 5.724 | 3.15 | 2.34 | 0.75 | 2.224 | M16 x 2.0P | 1 | 2.30 |

| 5011-460-A64-315 | BT40xMLD1"-3.15" | 5.724 | 3.15 | 2.49 | 1 | 2.362 | M16 x 2.0P | 1 | 2.20 |

| 5011-460-A72-400 | BT40xMLD1-1/4"-4" | 6.575 | 4 | 2.8 | 1.25 | 2.795 | M16 x 2.0P | 2 | 2.70 |

| 5012-460-A32-400 | BT50xMLD1/2"-4" | 8.008 | 4 | 1.84 | 0.5 | 1.654 | M12 x 1.75P | 1 | 4.60 |

| 5012-460-A40-400 | BT50xMLD5/8"-4" | 8.008 | 4 | 2.23 | 0.625 | 1.889 | M12 x 1.75P | 1 | 4.90 |

| 5012-460-A48-400 | BT50xMLD3/4"-4" | 8.008 | 4 | 2.34 | 0.75 | 2.224 | M16 x 2.0P | 1 | 4.50 |

| 5012-460-A64-413 | BT50xMLD1"-4.13" | 8.14 | 4.13 | 2.49 | 1 | 2.362 | M16 x 2.0P | 1 | 4.80 |

| 5012-460-A64-512 | BT50xMLD1"- 5.12" | 9.126 | 5.12 | 2.49 | 1 | 2.362 | M16 x 2.0P | 1 | 5.70 |

| 5012-460-A72-400 | BT50xMLD1-1/4"-4" | 8.008 | 4 | 2.8 | 1.25 | 2.795 | M24 x 3.0P | 1 | 4.90 |

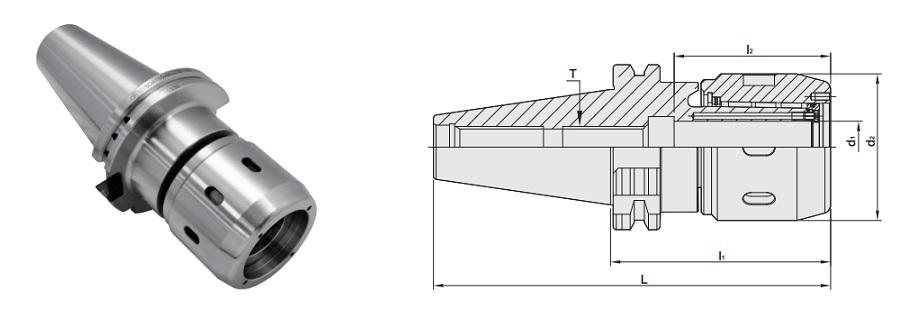

CAT/MLD MULTI-LOCK MILLING CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|

| 5031-460-A32-335 | CAT40xMLD1/2"-3.35" | 6.03 | 3.35 | 1.84 | 0.5 | 1.654 | M12 x 1.75P | 1.80 |

| 5031-460-A40-350 | CAT40xMLD5/8"-3.5" | 6.187 | 3.5 | 2.23 | 0.625 | 1.889 | M12 x 1.75P | 1.90 |

| 5031-460-A48-400 | CAT40xMLD3/4"-4" | 6.687 | 4 | 2.34 | 0.75 | 2.224 | 5/8"-11 | 1.90 |

| 5031-460-A48-600 | CAT40xMLD3/4"-6" | 8.687 | 6 | 2.34 | 0.75 | 2.224 | 5/8"-11 | 2.10 |

| 5031-460-A64-400 | CAT40xMLD1"-4" | 6.687 | 4 | 2.49 | 1 | 2.362 | 5/8"-11 | 2.00 |

| 5031-460-A72-420 | CAT40xMLD1-1/4"-4.2" | 6.887 | 4.2 | 2.8 | 1.25 | 2.795 | 5/8"-11 | 2.50 |

| 5031-460-A72-600 | CAT40xMLD1-1/4"-6" | 8.687 | 6 | 2.8 | 1.25 | 2.795 | 5/8"-11 | 2.70 |

| 5032-460-A32-350 | CAT50xMLD1/2"-3.5" | 7.5 | 3.5 | 1.84 | 0.5 | 1.654 | M12 x 1.75P | 2.50 |

| 5032-460-A40-350 | CAT50xMLD5/8"-3.5" | 7.5 | 3.5 | 2.23 | 0.625 | 1.889 | M12 x 1.75P | 2.70 |

| 5032-460-A48-400 | CAT50xMLD3/4"-4" | 8 | 4 | 2.34 | 0.75 | 2.224 | 5/8"-11 | 2.50 |

| 5032-460-A48-600 | CAT50xMLD3/4"-6" | 10 | 6 | 2.34 | 0.75 | 2.224 | 5/8"-11 | 2.80 |

| 5032-460-A64-400 | CAT50xMLD1"-4" | 8 | 4 | 2.49 | 1 | 2.362 | 5/8"-11 | 2.90 |

| 5032-460-A72-413 | CAT50xMLD1-1/4"-4.13" | 8.13 | 4.13 | 2.8 | 1.25 | 2.795 | 1"-8 | 2.70 |

| 5032-460-A72-600 | CAT50xMLD1-1/4"-6" | 10 | 6 | 2.8 | 1.25 | 2.795 | 5/8"-11 | 3.00 |

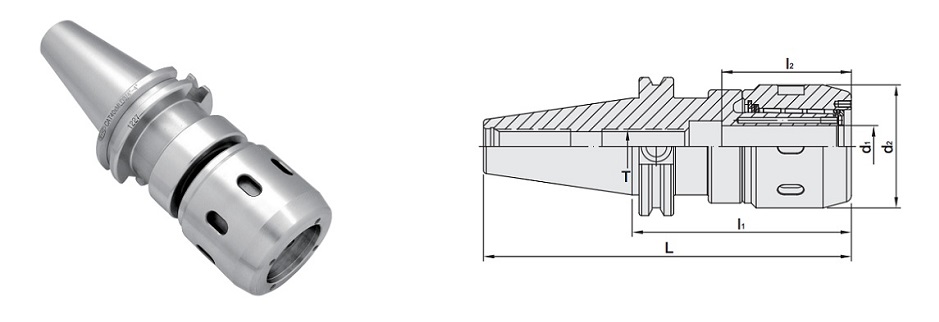

DAT/MLD MULTI-LOCK MILLING CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|

| 5050-460-012-080 | DAT30xMLD12-80 | 127.8 | 80 | 46.7 | 12 | 42 | M12 x 1.75P | 1.40 |

| 5050-460-016-080 | DAT30xMLD16-80 | 127.8 | 80 | 56.7 | 16 | 48 | M12 x 1.75P | 1.60 |

| 5050-460-020-085 | DAT30xMLD20-85 | 132.8 | 85 | 59.3 | 20 | 56.5 | M16 x 2.0P | 1.90 |

| 5050-460-020-100 | DAT30xMLD20-100 | 147.8 | 100 | 59.3 | 20 | 56.5 | M16 x 2.0P | 2.10 |

| 5051-460-012-075 | DAT40xMLD12-75 | 143.4 | 75 | 46.7 | 12 | 42 | M12 x 1.75P | 2.10 |

| 5051-460-016-080 | DAT40xMLD16-80 | 148.4 | 80 | 56.7 | 16 | 48 | M12 x 1.75P | 2.20 |

| 5051-460-020-085 | DAT40xMLD20-85 | 153.4 | 85 | 59.3 | 20 | 56.5 | M16 x 2.0P | 2.40 |

| 5051-460-020-135 | DAT40xMLD20-135 | 203.4 | 135 | 59.3 | 20 | 56.5 | M16 x 2.0P | 2.50 |

| 5051-460-025-095 | DAT40xMLD25-95 | 163.4 | 95 | 58.2 | 25 | 60 | M16 x 2.0P | 2.00 |

| 5051-460-032-105 | DAT40xMLD32-105 | 173.4 | 105 | 71.7 | 32 | 71 | M16 x 2.0P | 2.70 |

| 5051-460-032-135 | DAT40xMLD32-135 | 203.4 | 135 | 71.7 | 32 | 71 | M16 x 2.0P | 3.00 |

| 5052-460-012-075 | DAT50xMLD12-75 | 176.75 | 75 | 46.7 | 12 | 42 | M12 x 1.75P | 3.20 |

| 5052-460-016-075 | DAT50xMLD16-75 | 176.75 | 75 | 56.7 | 16 | 48 | M12 x 1.75P | 3.20 |

| 5052-460-020-105 | DAT50xMLD20-105 | 206.75 | 105 | 59.3 | 20 | 56.5 | M16 x 2.0P | 4.50 |

| 5052-460-020-150 | DAT50xMLD20-150 | 251.75 | 150 | 59.3 | 20 | 56.5 | M16 x 2.0P | 4.90 |

| 5052-460-025-105 | DAT50xMLD25-105 | 206.75 | 105 | 58.2 | 25 | 60 | M24 x 3.0P | 4.10 |

| 5052-460-032-105 | DAT50xMLD32-105 | 206.75 | 105 | 71.7 | 32 | 71 | M24 x 3.0P | 5.10 |

| 5052-460-032-135 | DAT50xMLD32-135 | 236.75 | 135 | 71.7 | 32 | 71 | M24 x 3.0P | 5.90 |

| 5052-460-042-115 | DAT50xMLD42-115 | 216.75 | 115 | 84.8 | 42 | 90 | M24 x 3.0P | 5.00 |

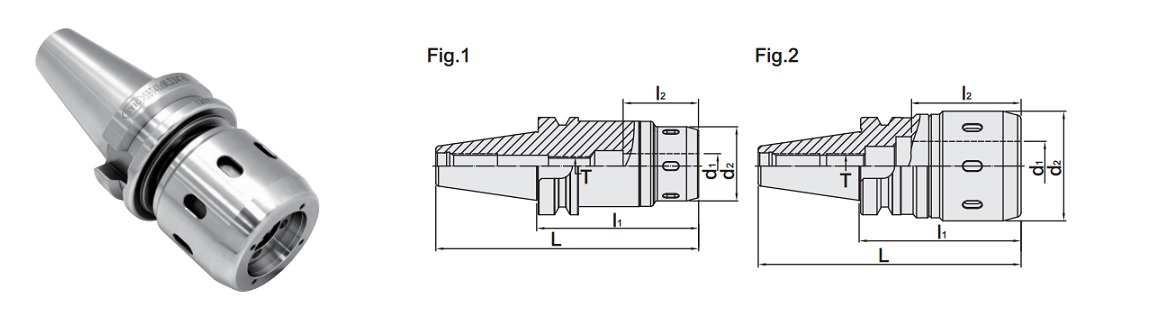

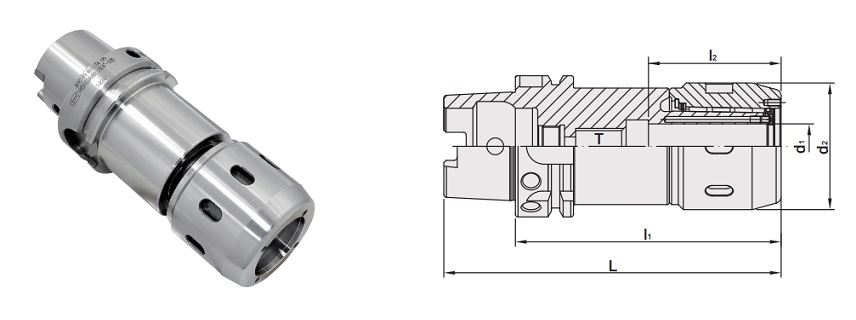

DualDRIVE+ SBT/MLD MULTI-LOCK MILLING CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | T | Fig. | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|

| 5025-460-012-080 | SBT30xMLD12-80 | 128.4 | 80 | 46.7 | 12 | 42 | M12 x 1.75P | 2 | 1.00 |

| 5025-460-016-075 | SBT30xMLD16-75 | 123.4 | 75 | 56.7 | 16 | 48 | M12 x 1.75P | 1 | 1.20 |

| 5025-460-020-080 | SBT30xMLD20-80 | 128.4 | 80 | 59.3 | 20 | 56.5 | M12 x 1.75P | 2 | 1.90 |

| 5025-460-020-090 | SBT30xMLD20-90 | 138.4 | 90 | 59.3 | 20 | 56.5 | M16 x 2.0P | 2 | 2.00 |

| 5025-460-025-090 | SBT30xMLD25-90 | 138.4 | 90 | 58.2 | 25 | 60 | M16 x 2.0P | 2 | 1.80 |

| 5026-460-012-075 | SBT40xMLD12-75 | 140.4 | 75 | 46.7 | 12 | 42 | M12 x 1.75P | 1 | 1.50 |

| 5026-460-012-105 | SBT40xMLD12-105 | 170.4 | 105 | 46.7 | 12 | 42 | M12 x 1.75P | 1 | 2.00 |

| 5026-460-012-135 | SBT40xMLD12-135 | 200.4 | 135 | 46.7 | 12 | 42 | M12 x 1.75P | 1 | 2.10 |

| 5026-460-016-075 | SBT40xMLD16-75 | 140.4 | 75 | 56.7 | 16 | 48 | M12 x 1.75P | 1 | 1.70 |

| 5026-460-016-105 | SBT40xMLD16-105 | 170.4 | 105 | 56.7 | 16 | 48 | M12 x 1.75P | 1 | 2.30 |

| 5026-460-016-135 | SBT40xMLD16-135 | 200.4 | 135 | 56.7 | 16 | 48 | M12 x 1.75P | 1 | 2.40 |

| 5026-460-020-080 | SBT40xMLD20-80 | 145.4 | 80 | 59.3 | 20 | 56.5 | M16 x 2.0P | 1 | 2.30 |

| 5026-460-020-100 | SBT40xMLD20-100 | 165.4 | 100 | 59.3 | 20 | 56.5 | M16 x 2.0P | 1 | 2.50 |

| 5026-460-020-135 | SBT40xMLD20-135 | 200.4 | 135 | 59.3 | 20 | 56.5 | M16 x 2.0P | 1 | 2.80 |

| 5026-460-025-085 | SBT40xMLD25-85 | 150.4 | 85 | 58.2 | 25 | 60 | M16 x 2.0P | 1 | 2.20 |

| 5026-460-025-100 | SBT40xMLD25-100 | 165.4 | 100 | 58.2 | 25 | 60 | M16 x 2.0P | 1 | 2.40 |

| 5026-460-032-095 | SBT40xMLD32-95 | 160.4 | 95 | 71.7 | 32 | 71 | M16 x 2.0P | 2 | 2.70 |

| 5026-460-032-105 | SBT40xMLD32-105 | 170.4 | 105 | 71.7 | 32 | 71 | M16 x 2.0P | 2 | 2.70 |

| 5026-460-032-135 | SBT40xMLD32-135 | 200.4 | 135 | 71.7 | 32 | 71 | M16 x 2.0P | 2 | 3.00 |

| 5027-460-012-105 | SBT50xMLD12-105 | 206.8 | 105 | 46.7 | 12 | 42 | M12 x 1.75P | 1 | 4.60 |

| 5027-460-012-135 | SBT50xMLD12-135 | 236.8 | 135 | 46.7 | 12 | 42 | M12 x 1.75P | 1 | 5.10 |

| 5027-460-012-165 | SBT50xMLD12-165 | 266.8 | 165 | 46.7 | 12 | 42 | M12 x 1.75P | 1 | 5.80 |

| 5027-460-016-105 | SBT50xMLD16-105 | 206.8 | 105 | 56.7 | 16 | 48 | M12 x 1.75P | 1 | 4.90 |

| 5027-460-016-135 | SBT50xMLD16-135 | 236.8 | 135 | 56.7 | 16 | 48 | M12 x 1.75P | 1 | 5.60 |

| 5027-460-016-165 | SBT50xMLD16-165 | 266.8 | 165 | 56.7 | 16 | 48 | M12 x 1.75P | 1 | 6.50 |

| 5027-460-020-105 | SBT50xMLD20-105 | 206.8 | 105 | 59.3 | 20 | 56.5 | M16 x 2.0P | 1 | 4.50 |

| 5027-460-020-150 | SBT50xMLD20-150 | 251.8 | 150 | 59.3 | 20 | 56.5 | M16 x 2.0P | 1 | 4.90 |

| 5027-460-025-100 | SBT50xMLD25-100 | 201.8 | 100 | 58.2 | 25 | 60 | M16 x 2.0P | 1 | 4.80 |

| 5027-460-025-130 | SBT50xMLD25-130 | 231.8 | 130 | 58.2 | 25 | 60 | M16 x 2.0P | 1 | 5.70 |

| 5027-460-032-105 | SBT50xMLD32-105 | 206.8 | 105 | 71.7 | 32 | 71 | M24 x 3.0P | 1 | 5.00 |

| 5027-460-032-135 | SBT50xMLD32-135 | 236.8 | 135 | 71.7 | 32 | 71 | M24 x 3.0P | 1 | 5.20 |

| 5027-460-032-165 | SBT50xMLD32-165 | 266.8 | 165 | 71.7 | 32 | 71 | M24 x 3.0P | 1 | 6.70 |

| 5027-460-042-115 | SBT50xMLD42-115 | 216.8 | 115 | 84.8 | 42 | 90 | M24 x 3.0P | 1 | 5.50 |

| 5027-460-042-130 | SBT50xMLD42-130 | 231.8 | 130 | 84.8 | 42 | 90 | M24 x 3.0P | 1 | 6.50 |

| 5027-460-042-165 | SBT50xMLD42-165 | 266.8 | 165 | 84.8 | 42 | 90 | M24 x 3.0P | 1 | 7.70 |

| 5025-460-A32-315 | SBT30xMLD1/2"-3.15" | 5.05 | 3.15 | 1.84 | 0.5 | 1.654 | M12 x 1.75P | 2 | 1.00 |

| 5025-460-A40-295 | SBT30xMLD5/8"-2.95" | 4.86 | 2.95 | 2.23 | 0.625 | 1.889 | M12 x 1.75P | 1 | 1.20 |

| 5025-460-A48-354 | SBT30xMLD3/4"-3.54" | 5.449 | 3.54 | 2.34 | 0.75 | 2.224 | M12 x 1.75P | 2 | 1.90 |

| 5025-460-A64-354 | SBT30xMLD1"-3.54" | 5.449 | 3.54 | 2.49 | 1 | 2.36 | M16 x 2.0P | 2 | 1.80 |

| 5026-460-A32-295 | SBT40xMLD1/2"-2.95" | 5.528 | 2.95 | 1.84 | 0.5 | 1.654 | M12 x 1.75P | 1 | 1.50 |

| 5026-460-A40-295 | SBT40xMLD5/8"-2.95" | 5.528 | 2.95 | 2.23 | 0.625 | 1.889 | M12 x 1.75P | 1 | 1.70 |

| 5026-460-A48-315 | SBT40xMLD3/4"-3.15" | 5.724 | 3.15 | 2.34 | 0.75 | 2.224 | M16 x 2.0P | 1 | 2.30 |

| 5026-460-A64-335 | SBT40xMLD1"-3.35" | 5.921 | 3.35 | 2.49 | 1 | 2.36 | M16 x 2.0P | 1 | 2.20 |

| 5026-460-A72-400 | SBT40xMLD1-1/4"-4" | 6.575 | 4 | 2.8 | 1.25 | 2.795 | M16 x 2.0P | 2 | 2.70 |

| 5027-460-A32-400 | SBT50xMLD1/2"-4" | 8.008 | 4 | 1.84 | 0.5 | 1.654 | M12 x 1.75P | 1 | 4.60 |

| 5027-460-A40-400 | SBT50xMLD5/8"-4" | 8.008 | 4 | 2.23 | 0.625 | 1.889 | M12 x 1.75P | 1 | 4.90 |

| 5027-460-A48-400 | SBT50xMLD3/4"-4" | 8.008 | 4 | 2.34 | 0.75 | 2.224 | M16 x 2.0P | 1 | 4.50 |

| 5027-460-A64-413 | SBT50xMLD1"-4.13" | 8.14 | 4.13 | 2.49 | 1 | 2.36 | M16 x 2.0P | 1 | 4.80 |

| 5027-460-A64-512 | SBT50xMLD1"-5.12" | 9.126 | 5.12 | 2.49 | 1 | 2.36 | M16 x 2.0P | 1 | 5.70 |

| 5027-460-A72-400 | SBT50xMLD1-1/4"-4" | 8.008 | 4 | 2.8 | 1.25 | 2.795 | M24 x 3.0P | 1 | 4.90 |

DualDRIVE+ SCAT/MLD MULTI-LOCK MILLING CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|

| 5043-460-A32-335 | SCAT40xMLD1/2"-3.35" | 6.03 | 3.35 | 1.84 | 0.5 | 1.654 | M12 x 1.75P | 1.80 |

| 5043-460-A40-350 | SCAT40xMLD5/8"-3.5" | 6.187 | 3.5 | 2.23 | 0.625 | 1.889 | M12 x 1.75P | 1.90 |

| 5043-460-A48-400 | SCAT40xMLD3/4"-4" | 6.687 | 4 | 2.34 | 0.75 | 2.224 | 5/8" - 11 | 1.90 |

| 5043-460-A48-600 | SCAT40xMLD3/4"-6" | 8.687 | 6 | 2.34 | 0.75 | 2.224 | 5/8" - 11 | 2.10 |

| 5043-460-A64-400 | SCAT40xMLD1"-4" | 6.687 | 4 | 2.49 | 1 | 2.362 | 5/8" - 11 | 2.00 |

| 5043-460-A72-420 | SCAT40xMLD1-1/4"-4.2" | 6.887 | 4.2 | 2.8 | 1.25 | 2.795 | 5/8" - 11 | 2.50 |

| 5043-460-A72-600 | SCAT40xMLD1-1/4"-6" | 8.687 | 6 | 2.8 | 1.25 | 2.795 | 5/8" - 11 | 2.70 |

| 5044-460-A32-350 | SCAT50xMLD1/2"-3.5" | 7.5 | 3.5 | 1.84 | 0.5 | 1.654 | M12 x 1.75P | 2.50 |

| 5044-460-A40-350 | SCAT50xMLD5/8"-3.5" | 7.5 | 3.5 | 2.23 | 0.625 | 1.889 | M12 x 1.75P | 2.70 |

| 5044-460-A48-400 | SCAT50xMLD3/4"-4" | 8 | 4 | 2.34 | 0.75 | 2.224 | 5/8" - 11 | 2.50 |

| 5044-460-A48-600 | SCAT50xMLD3/4"-6" | 10 | 6 | 2.34 | 0.75 | 2.224 | 5/8" - 11 | 2.80 |

| 5044-460-A64-400 | SCAT50xMLD1"-4" | 8 | 4 | 2.49 | 1 | 2.362 | 5/8"- 11 | 2.90 |

| 5044-460-A72-413 | SCAT50xMLD1-1/4"-4.13" | 8.13 | 4.13 | 2.8 | 1.25 | 2.795 | 1" - 8 | 2.70 |

| 5044-460-A72-600 | SCAT50xMLD1-1/4"-6" | 10 | 6 | 2.8 | 1.25 | 2.795 | 5/8" - 11 | 3.00 |

DualDRIVE+ SDAT/MLD MULTI-LOCK MILLING CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|

| 5066-460-012-075 | SDAT40xMLD12-75 | 143.4 | 75 | 46.7 | 12 | 42 | M12 x 1.75P | 2.10 |

| 5066-460-016-080 | SDAT40xMLD16-80 | 148.4 | 80 | 56.7 | 16 | 48 | M12 x 1.75P | 2.20 |

| 5066-460-020-085 | SDAT40xMLD20-85 | 153.4 | 85 | 59.3 | 20 | 56.5 | M16 x 2.0P | 2.40 |

| 5066-460-020-135 | SDAT40xMLD20-135 | 203.4 | 135 | 59.3 | 20 | 56.5 | M16 x 2.0P | 2.50 |

| 5066-460-025-095 | SDAT40xMLD25-95 | 163.4 | 95 | 58.2 | 25 | 60 | M16 x 2.0P | 2.00 |

| 5066-460-032-105 | SDAT40xMLD32-105 | 173.4 | 105 | 71.7 | 32 | 71 | M16 x 2.0P | 2.70 |

| 5066-460-032-135 | SDAT40xMLD32-135 | 203.4 | 135 | 71.7 | 32 | 71 | M16 x 2.0P | 3.00 |

| 5067-460-012-075 | SDAT50xMLD12-75 | 176.75 | 75 | 46.7 | 12 | 42 | M12 x 1.75P | 3.20 |

| 5067-460-016-075 | SDAT50xMLD16-75 | 176.75 | 75 | 56.7 | 16 | 48 | M12 x 1.75P | 3.20 |

| 5067-460-020-105 | SDAT50xMLD20-105 | 206.75 | 105 | 59.3 | 20 | 56.5 | M16 x 2.0P | 4.50 |

| 5067-460-020-150 | SDAT50xMLD20-150 | 251.75 | 150 | 59.3 | 20 | 56.5 | M16 x 2.0P | 4.90 |

| 5067-460-025-105 | SDAT50xMLD25-105 | 206.75 | 105 | 58.2 | 25 | 60 | M24 x 3.0P | 4.10 |

| 5067-460-032-105 | SDAT50xMLD32-105 | 206.75 | 105 | 71.7 | 32 | 71 | M24 x 3.0P | 5.10 |

| 5067-460-032-135 | SDAT50xMLD32-135 | 236.75 | 135 | 71.7 | 32 | 71 | M24 x 3.0P | 5.90 |

| 5067-460-042-115 | SDAT50xMLD42-115 | 216.75 | 115 | 84.8 | 42 | 90 | M24 x 3.0P | 5.00 |

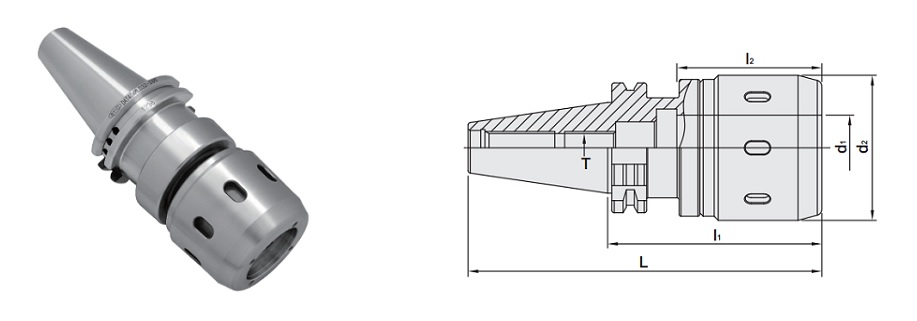

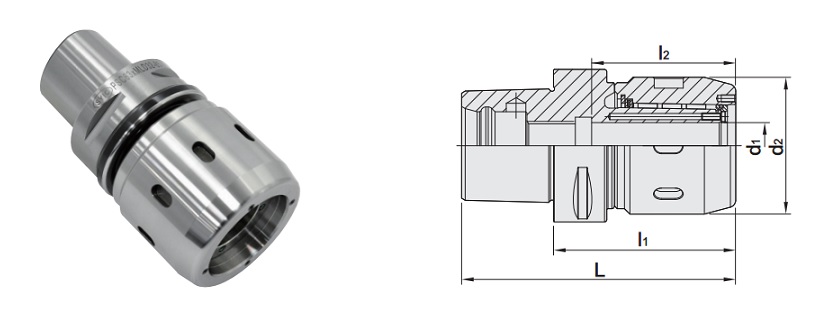

HSK/MLD MULTI-LOCK MILLING CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|

| 5072-460-012-100 | HSK50AxMLD12-100 | 125 | 100 | 46.7 | 12 | 42 | - | 1.52 |

| 5072-460-016-100 | HSK50AxMLD16-100 | 125 | 100 | 56.7 | 16 | 48 | - | 1.59 |

| 5072-460-020-120 | HSK50AxMLD20-120 | 145 | 120 | 59.3 | 20 | 56.5 | M12x1.75P | 1.62 |

| 5073-460-012-090 | HSK63AxMLD12-90 | 122 | 90 | 46.7 | 12 | 42 | - | 1.62 |

| 5073-460-016-100 | HSK63AxMLD16-100 | 132 | 100 | 56.7 | 16 | 48 | - | 1.62 |

| 5073-460-020-120 | HSK63AxMLD20-120 | 152 | 120 | 59.3 | 20 | 56.5 | M16x2.0P | 1.68 |

| 5073-460-025-105 | HSK63AxMLD25-105 | 137 | 105 | 58.2 | 25 | 60 | - | 1.82 |

| 5073-460-032-120 | HSK63AxMLD32-120 | 152 | 120 | 71.7 | 32 | 71 | - | 1.76 |

| 5075-460-012-115 | HSK100AxMLD12-115 | 165 | 115 | 46.7 | 12 | 42 | M12x1.75P | 3.10 |

| 5075-460-016-120 | HSK100AxMLD16-120 | 170 | 120 | 56.7 | 16 | 48 | M12x1.75P | 3.10 |

| 5075-460-020-120 | HSK100AxMLD20-120 | 170 | 120 | 59.3 | 20 | 56.5 | M16x2.0P | 3.40 |

| 5075-460-025-115 | HSK100AxMLD25-115 | 165 | 115 | 58.2 | 25 | 60 | - | 3.30 |

| 5075-460-032-120 | HSK100AxMLD32-120 | 170 | 120 | 71.7 | 32 | 71 | - | 3.40 |

| 5076-460-020-135 | HSK125AxMLD20-135 | 198 | 135 | 59.3 | 20 | 56.5 | - | 6.70 |

| 5076-460-020-165 | HSK125AxMLD20-165 | 228 | 165 | 59.3 | 20 | 56.5 | M12x1.75P | 7.60 |

| 5076-460-025-135 | HSK125AxMLD25-135 | 198 | 135 | 58.2 | 25 | 60 | M16x2.0P | 7.10 |

| 5076-460-032-135 | HSK125AxMLD32-135 | 198 | 135 | 71.7 | 32 | 71 | - | 7.80 |

| 5076-460-032-165 | HSK125AxMLD32-165 | 228 | 165 | 71.7 | 32 | 71 | M16x2.0P | 9.10 |

| 5076-460-042-135 | HSK125AxMLD42-135 | 198 | 135 | 84.8 | 42 | 90 | - | 8.00 |

| 5072-460-A32-400 | HSK50AxMLD1/2"-4" | 4.984 | 4 | 1.84 | 0.5 | 1.654 | - | 1.52 |

| 5072-460-A40-394 | HSK50AxMLD5/8"-3.94" | 4.921 | 3.94 | 2.23 | 0.625 | 1.889 | - | 1.62 |

| 5072-460-A48-400 | HSK50AxMLD3/4"-4" | 4.984 | 4 | 2.34 | 0.75 | 2.224 | - | 1.62 |

| 5073-460-A32-354 | HSK63AxMLD1/2"-3.54" | 4.803 | 3.54 | 1.84 | 0.5 | 1.654 | - | 1.72 |

| 5073-460-A40-394 | HSK63AxMLD5/8"-3.94" | 5.197 | 3.94 | 2.23 | 0.625 | 1.889 | - | 1.75 |

| 5073-460-A48-400 | HSK63AxMLD3/4"-4" | 5.26 | 4 | 2.34 | 0.75 | 2.224 | - | 1.80 |

| 5073-460-A64-413 | HSK63AxMLD1"-4.13" | 5.394 | 4.13 | 2.49 | 1 | 2.362 | - | 1.65 |

| 5073-460-A72-472 | HSK63AxMLD1-1/4"-4.72" | 5.984 | 4.72 | 2.8 | 1.25 | 2.795 | - | 1.68 |

| 5075-460-A32-453 | HSK100AxMLD1/2"-4.53" | 6.496 | 4.53 | 1.84 | 0.5 | 1.654 | M12x1.75P | 1.65 |

| 5075-460-A40-453 | HSK100AxMLD5/8"-4.53" | 6.496 | 4.53 | 2.23 | 0.625 | 1.889 | M12x1.75P | 1.65 |

| 5075-460-A48-472 | HSK100AxMLD3/4"-4.72" | 6.693 | 4.72 | 2.34 | 0.75 | 2.224 | - | 1.70 |

| 5075-460-A64-453 | HSK100AxMLD1"-4.53" | 6.496 | 4.53 | 2.49 | 1 | 2.362 | - | 1.72 |

| 5075-460-A72-472 | HSK100AxMLD1-1/4"-4.72" | 6.693 | 4.72 | 2.8 | 1.25 | 2.795 | - | 1.76 |

PSC/MLD MULTI-LOCK MILLING CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|

| 5142-460-016-065 | PSC50xMLD16-65 | 95 | 65 | 56.7 | 16 | 48 | 1.00 |

| 5142-460-016-090 | PSC50xMLD16-90 | 120 | 90 | 56.7 | 16 | 48 | 1.50 |

| 5142-460-020-075 | PSC50xMLD20-75 | 105 | 75 | 59.3 | 20 | 56.5 | 1.20 |

| 5142-460-020-090 | PSC50xMLD20-90 | 120 | 90 | 59.3 | 20 | 56.5 | 1.40 |

| 5142-460-025-085 | PSC50xMLD25-85 | 115 | 85 | 58.2 | 25 | 60 | 1.60 |

| 5142-460-025-105 | PSC50xMLD25-105 | 135 | 105 | 58.2 | 25 | 60 | 1.80 |

| 5142-460-032-090 | PSC50xMLD32-90 | 120 | 90 | 71.7 | 32 | 71 | 1.90 |

| 5143-460-016-070 | PSC63xMLD16-70 | 108 | 70 | 56.7 | 16 | 48 | 1.20 |

| 5143-460-016-090 | PSC63xMLD16-90 | 128 | 90 | 56.7 | 16 | 48 | 1.40 |

| 5143-460-020-075 | PSC63xMLD20-75 | 113 | 75 | 59.3 | 20 | 56.5 | 1.40 |

| 5143-460-020-090 | PSC63xMLD20-90 | 128 | 90 | 59.3 | 20 | 56.5 | 1.60 |

| 5143-460-025-080 | PSC63xMLD25-80 | 118 | 80 | 58.2 | 25 | 60 | 1.70 |

| 5143-460-025-090 | PSC63xMLD25-90 | 128 | 90 | 58.2 | 25 | 60 | 1.90 |

| 5143-460-032-085 | PSC63xMLD32-85 | 123 | 85 | 71.7 | 32 | 71 | 2.20 |

| 5143-460-032-105 | PSC63xMLD32-105 | 143 | 105 | 71.7 | 32 | 71 | 2.40 |

| 5144-460-016-070 | PSC80xMLD16-70 | 118 | 70 | 56.7 | 16 | 48 | 2.30 |

| 5144-460-016-105 | PSC80xMLD16-105 | 153 | 105 | 56.7 | 16 | 48 | 2.50 |

| 5144-460-020-080 | PSC80xMLD20-80 | 128 | 80 | 59.3 | 20 | 56.5 | 2.60 |

| 5144-460-020-105 | PSC80xMLD20-105 | 153 | 105 | 59.3 | 20 | 56.5 | 2.80 |

| 5144-460-025-085 | PSC80xMLD25-85 | 133 | 85 | 58.2 | 25 | 60 | 2.80 |

| 5144-460-025-105 | PSC80xMLD25-105 | 153 | 105 | 58.2 | 25 | 60 | 3.10 |

| 5144-460-032-090 | PSC80xMLD32-90 | 138 | 90 | 71.7 | 32 | 71 | 2.90 |

| 5144-460-032-105 | PSC80xMLD32-105 | 153 | 105 | 71.7 | 32 | 71 | 3.10 |

| 5146-460-016-090 | PSC100xMLD16-90 | 150 | 90 | 56.7 | 16 | 48 | 4.08 |

| 5146-460-016-105 | PSC100xMLD16-105 | 165 | 105 | 56.7 | 16 | 48 | 4.31 |

| 5146-460-020-095 | PSC100xMLD20-95 | 155 | 95 | 59.3 | 20 | 56.5 | 4.68 |

| 5146-460-020-105 | PSC100xMLD20-105 | 165 | 105 | 59.3 | 20 | 56.5 | 4.82 |

| 5146-460-025-095 | PSC100xMLD25-95 | 155 | 95 | 58.2 | 25 | 60 | 4.51 |

| 5146-460-025-105 | PSC100xMLD25-105 | 165 | 105 | 58.2 | 25 | 60 | 4.69 |

| 5146-460-032-105 | PSC100xMLD32-105 | 165 | 105 | 71.1 | 32 | 71 | 4.71 |

| 5142-460-A40-250 | PSC50xMLD5/8"-2.5" | 3.681 | 2.5 | 2.23 | 0.625 | 1.889 | 1.00 |

| 5142-460-A40-350 | PSC50xMLD5/8"-3.5" | 4.681 | 3.5 | 2.23 | 0.625 | 1.889 | 1.50 |

| 5142-460-A48-300 | PSC50xMLD3/4"-3" | 4.181 | 3 | 2.34 | 0.75 | 2.224 | 1.20 |

| 5142-460-A48-350 | PSC50xMLD3/4"-3.5" | 4.681 | 3.5 | 2.34 | 0.75 | 2.224 | 1.40 |

| 5142-460-A64-335 | PSC50xMLD1"-3.35" | 4.531 | 3.35 | 2.49 | 1 | 2.362 | 1.60 |

| 5142-460-A64-413 | PSC50xMLD1"-4.13" | 5.314 | 4.13 | 2.49 | 1 | 2.362 | 1.80 |

| 5142-460-A72-350 | PSC50xMLD1-1/4"-3.5" | 4.681 | 3.5 | 2.8 | 1.25 | 2.795 | 1.90 |

| 5143-460-A40-275 | PSC63xMLD5/8"-2.75" | 4.246 | 2.75 | 2.23 | 0.625 | 1.889 | 1.20 |

| 5143-460-A40-350 | PSC63xMLD5/8"-3.5" | 4.996 | 3.5 | 2.23 | 0.625 | 1.889 | 1.40 |

| 5143-460-A48-300 | PSC63xMLD3/4"-3" | 4.496 | 3 | 2.34 | 0.75 | 2.224 | 1.40 |

| 5143-460-A48-350 | PSC63xMLD3/4"-3.5" | 4.996 | 3.5 | 2.34 | 0.75 | 2.224 | 1.60 |

| 5143-460-A64-315 | PSC63xMLD1"-3.15" | 4.645 | 3.15 | 2.49 | 1 | 2.362 | 1.70 |

| 5143-460-A64-350 | PSC63xMLD1"-3.5" | 4.996 | 3.5 | 2.49 | 1 | 2.362 | 1.90 |

| 5143-460-A72-335 | PSC63xMLD1-1/4"-3.35" | 4.846 | 3.35 | 2.8 | 1.25 | 2.795 | 2.20 |

| 5143-460-A72-413 | PSC63xMLD1-1/4"-4.13" | 5.626 | 4.13 | 2.8 | 1.25 | 2.795 | 2.40 |

| 5144-460-A40-275 | PSC80xMLD5/8"-2.75" | 4.639 | 2.75 | 2.23 | 0.625 | 1.889 | 2.30 |

| 5144-460-A40-413 | PSC80xMLD5/8"-4.13" | 6.019 | 4.13 | 2.23 | 0.625 | 1.889 | 2.50 |

| 5144-460-A48-315 | PSC80xMLD3/4"-3.15" | 5.039 | 3.15 | 2.34 | 0.75 | 2.224 | 2.60 |

| 5144-460-A48-413 | PSC80xMLD3/4"-4.13" | 6.019 | 4.13 | 2.34 | 0.75 | 2.224 | 2.80 |

| 5144-460-A64-335 | PSC80xMLD1"-3.35" | 5.239 | 3.35 | 2.49 | 1 | 2.362 | 2.80 |

| 5144-460-A64-413 | PSC80xMLD1"-4.13" | 6.019 | 4.13 | 2.49 | 1 | 2.362 | 3.10 |

| 5144-460-A72-350 | PSC80xMLD1-1/4"-3.5" | 5.389 | 3.5 | 2.8 | 1.25 | 2.795 | 2.90 |

| 5144-460-A72-413 | PSC80xMLD1-1/4"-4.13" | 6.019 | 4.13 | 2.8 | 1.25 | 2.795 | 3.10 |

| 5146-460-A40-350 | PSC100xMLD5/8"-3.5" | 5.862 | 3.5 | 2.23 | 0.625 | 1.889 | 4.07 |

| 5146-460-A40-413 | PSC100xMLD5/8"-4.13" | 6.492 | 4.13 | 2.23 | 0.625 | 1.889 | 4.32 |

| 5146-460-A48-375 | PSC100xMLD3/4"-3.75" | 6.112 | 3.75 | 2.34 | 0.75 | 2.224 | 4.70 |

| 5146-460-A48-413 | PSC100xMLD3/4"-4.13" | 6.492 | 4.13 | 2.34 | 0.75 | 2.224 | 4.82 |

| 5146-460-A64-400 | PSC100xMLD1"-4" | 6.362 | 4 | 2.49 | 1 | 2.36 | 4.64 |

| 5146-460-A64-413 | PSC100xMLD1"-4.13" | 6.492 | 4.13 | 2.49 | 1 | 2.36 | 4.70 |

| 5146-460-A72-400 | PSC100xMLD1-1/4"-4" | 6.362 | 4 | 2.8 | 1.25 | 2.795 | 4.59 |

| 5146-460-A72-413 | PSC100xMLD1-1/4"-4.13" | 6.492 | 4.13 | 2.8 | 1.25 | 2.795 | 4.65 |

NT.MT/MLD MULTI-LOCK MILLING CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | D | d1 | d2 | T | WEIGHT (KGS) | |

|---|---|---|---|---|---|---|---|---|---|---|

| 5120-460-201/5-070 | NT30xMLD20-70 | 138.4 | 70 | 63.5 | 50 | 20 | 56.5 | 1/2" - 12 | M12 x 1.75P | 1.90 |

| 5121-460-201/5-070 | NT40xMLD20-70 | 163.4 | 70 | 63.5 | 52 | 20 | 56.5 | 5/8" - 11 | M16 x 2.0P | 2.30 |

| 5274-460-204-070 | R8xMLD20-70 | 174 | 70 | 63.5 | 52 | 20 | 56.5 | 7/16" - 20 | 1.90 | |

| 5180-460-321/5-090 | MTB5xMLD32-90 | 218.5 | 90 | 71.8 | 67 | 32 | 71 | 1" - 8 | M24 x 3.0P | 3.80 |

| 5121-460-321/5-085 | NT40xMLD32-85 | 178.4 | 85 | 71.8 | 67 | 32 | 71 | 5/8" - 11 | M16 x 2.0P | 2.60 |

| 5122-460-321/5-090 | NT50xMLD32-90 | 216.8 | 90 | 71.8 | 67 | 32 | 71 | 1" - 8 | M24 x 3.0P | 4.90 |

series:

The Assembly and Coolant Application of PSC/MLD Multi-Lock Milling Chuck

Coolant Applications of PRO-E Collet Chuck and MLD Multi-Lock Milling Chuck

Coolant Application of MLD Multi-Lock Milling Chuck

Installation of Set Screw for MLD Multi-Lock Milling Chuck

Coolant Applications of PRO-E Collet Chuck and MLD Multi-Lock Milling Chuck

Coolant Application of MLD Multi-Lock Milling Chuck

Installation of Set Screw for MLD Multi-Lock Milling Chuck

Back

Back