SYIC: Pioneering Tool Holders, Embracing the Automation Industry

Established in 1979, SYIC is a professional manufacturer of machinery tools and accessories, specializing in the production of precision tool holders, cutting tools, angle heads, workpiece clamping systems, measuring tools for machining centers, boring heads, high-precision collets, and more. Our produced tool holder tapers include: BMT, BT (ISO 7388-2 & MAS 403), CAT (ANSI/ASME B5.50), DAT (ISO 7388-1 & DIN 69871-A), HSK (ISO 12164), PSC (ISO 26623), VDI (DIN ISO 10889), and straight shank series. We hold ISO9001 and ISO14001 certifications, and our mission is to design, manufacture, and sell innovative products for the world's advanced markets, backed by over 300 patents. We have invested in advanced production equipment and measuring instruments from Japan and Europe, focusing on excellent quality control and process capabilities.

“Quality creates reputation, and reputation guarantees quality”

is our core value. With our professional technical capabilities, we provide comprehensive solutions to our customers, enhancing their processing efficiency and competitiveness. Guided by the mission of "First-class service, quality first," we are committed to delivering high-precision products to our customers.

As smart manufacturing and automated production receive increasing attention, our workpiece clamping systems and measuring tools for machining centers continue to be spotlighted. Traditional industries are facing a significant gap in technical succession. In the process of metal processing automation, we are entering a new era where reliance on manual machine operation is no longer sufficient, and automation has become an inevitable trend. The automated management of workpiece clamping systems enables flexible and rapid workpiece clamping, boosting production efficiency and effectively addressing labor shortages.

“Innovative Automation Solutions”

With the rise of Industry 4.0, the manufacturing industry is undergoing significant transformation. The introduction of automation technology allows production lines to execute tasks faster and more accurately, while reducing the likelihood of human errors. Automation extends beyond hardware development; software applications are also becoming increasingly crucial. From order management to production processes, software assistance enhances operational efficiency and reduces error rates. In terms of hardware, robotic arms and automatic feeding machines become crucial. The expansion of built-in trays and ATC tool magazines enables 24/7 uninterrupted operation, providing long-term profit opportunities for businesses.

In this era of automation, SYIC actively introduces data chip hole tool holders and AWC jig tool holders. The former reduces tool-setting time, enhances machine utilization rates, decreases the probability of human errors, optimizes tool management processes, and improves production efficiency through a tool identification system. The latter is suitable for machine equipment with a quick positioning clamping system, offering various clamping and locking methods. It pre-clamps workpieces and mold fixtures before processing, shortens setup time, and supports automation systems, thereby increasing production efficiency. SYIC is also actively implementing automation within its factories and manufacturing premium products that assist automation, helping customers build intelligent super factories and creating win-win situations.

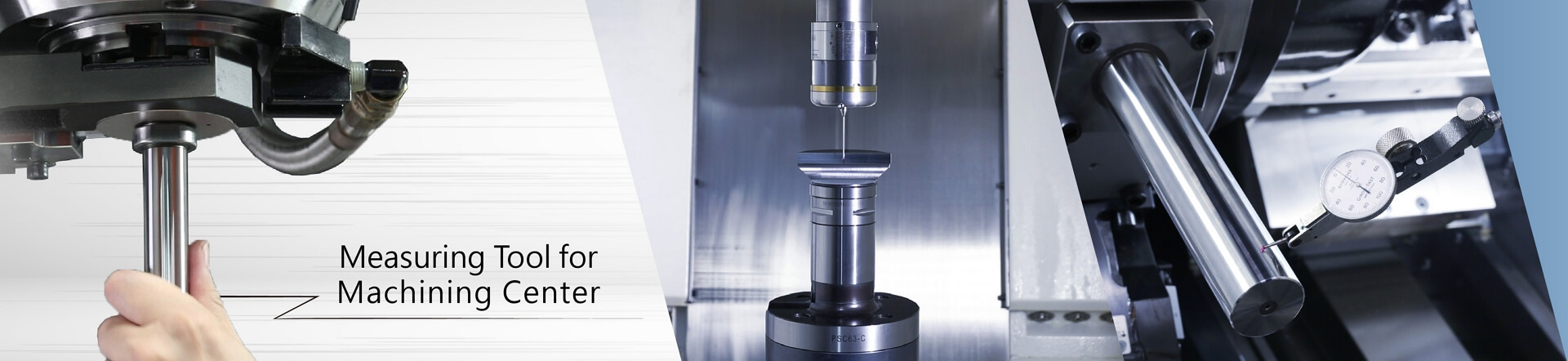

“Implementing Regular Machine Inspection”

In terms of machine inspection, SYIC provides spindle master bars, ATC alignment tool sets, SOG spindle origin gauges, and other tools, becoming the defense team for machines. Spindle collisions can lead to excessive runout accuracy, affecting workpiece processing accuracy and surface roughness. Additionally, collisions can impact the accuracy of machine tool changer systems, leading to tool change failures or even damaging spindles and tool holders. Our measuring tools help detect potential problems in machines regularly, reducing machine breakdown, ensuring improved processing accuracy, increasing production output, and extending the lifespan of spindles and tools.

SYIC is not only a leader in tool holders but also a promoter of automation in the industry. We integrate the concept of automation into our products and services, providing customers with more efficient and intelligent solutions.