- Home

- Products

- Tool Holder for Machining Center

- Others

- SLN Side Lock End Mill Holder

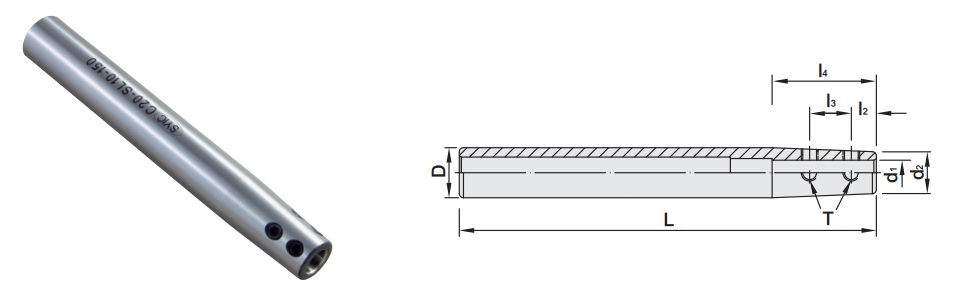

SLN Side Lock End Mill Holder

series:

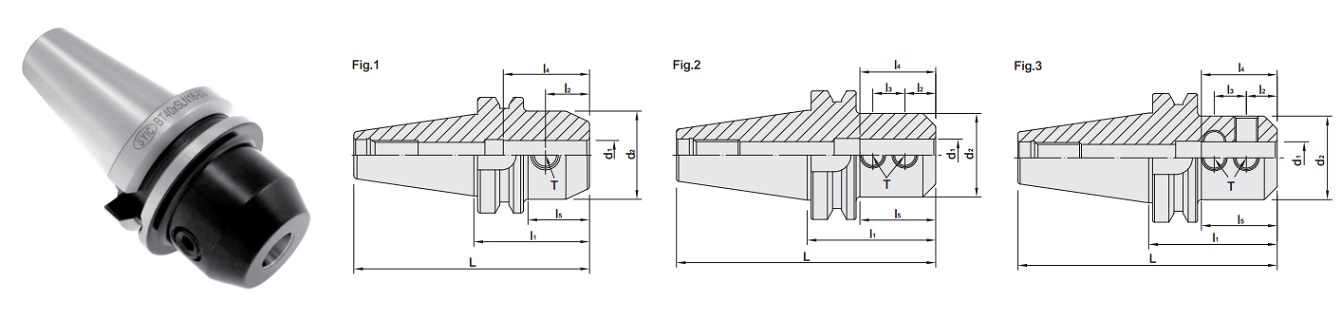

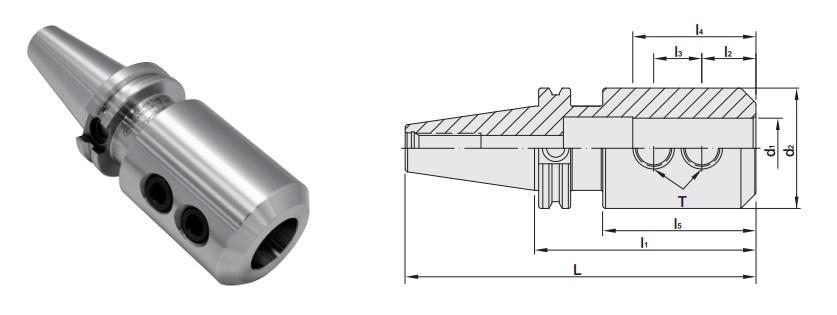

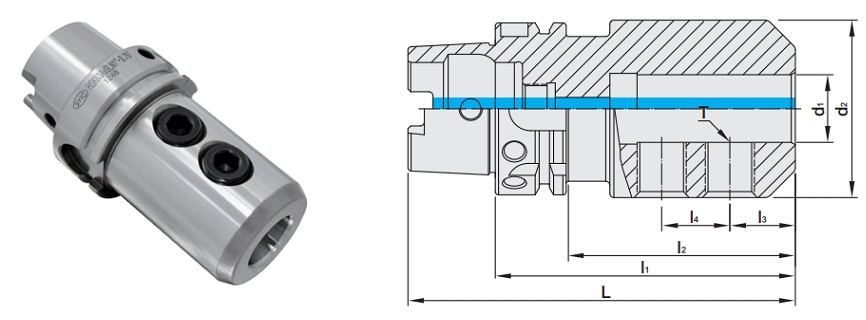

BT/SLN SIDE LOCK END MILL HOLDER

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | l5 | d1 | d2 | T | Fig. | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5010-653-006-060 | BT30xSLN6-60 | 108.4 | 60 | 18 | - | 35 | 33 | 6 | 25 | M6 x 1.0P | 1 | 0.55 |

| 5010-653-008-060 | BT30xSLN8-60 | 108.4 | 60 | 18 | - | 35 | 33 | 8 | 28 | M8 x 1.25P | 1 | 0.60 |

| 5010-653-010-060 | BT30xSLN10-60 | 108.4 | 60 | 20 | - | 39 | 35 | 10 | 35 | M10 x 1.5P | 1 | 0.70 |

| 5010-653-012-060 | BT30xSLN12-60 | 108.4 | 60 | 22.5 | - | 44 | 36 | 12 | 42 | M12 x 1.75P | 1 | 0.75 |

| 5010-653-016-075 | BT30xSLN16-75 | 123.4 | 75 | 24 | - | 47 | 53 | 16 | 48 | M14 x 2.0P | 1 | 1.05 |

| 5010-653-020-075 | BT30xSLN20-75 | 123.4 | 75 | 25 | - | 49 | 53 | 20 | 52 | M16 x 2.0P | 1 | 1.10 |

| 5010-653-025-090 | BT30xSLN25-90 | 138.4 | 90 | 24 | 25 | 58 | 68 | 25 | 65 | M18 x 2.0P | 2 | 1.70 |

| 5011-653-006-050 | BT40xSLN6-50 | 115.4 | 50 | 18 | - | 35 | 20 | 6 | 25 | M6 x 1.0P | 1 | 1.10 |

| 5011-653-006-150 | BT40xSLN6-150 | 215.4 | 150 | 18 | - | 35 | 113 | 6 | 25 | M6 x 1.0P | 1 | 1.32 |

| 5011-653-008-050 | BT40xSLN8-50 | 115.4 | 50 | 18 | - | 35 | 20 | 8 | 28 | M8 x 1.25P | 1 | 1.10 |

| 5011-653-008-150 | BT40xSLN8-150 | 215.4 | 150 | 18 | - | 35 | 113 | 8 | 28 | M8 x 1.25P | 1 | 1.30 |

| 5011-653-010-063 | BT40xSLN10-63 | 128.4 | 63 | 20 | - | 39 | 33 | 10 | 35 | M10 x 1.5P | 1 | 1.25 |

| 5011-653-010-150 | BT40xSLN10-150 | 215.4 | 150 | 20 | - | 39 | 113 | 10 | 35 | M10 x 1.5P | 1 | 1.40 |

| 5011-653-012-063 | BT40xSLN12-63 | 128.4 | 63 | 22.5 | - | 44 | 33 | 12 | 42 | M12 x 1.75P | 1 | 1.30 |

| 5011-653-012-150 | BT40xSLN12-150 | 215.4 | 150 | 22.5 | - | 44 | 116 | 12 | 42 | M12 x 1.75P | 1 | 1.53 |

| 5011-653-016-063 | BT40xSLN16-63 | 128.4 | 63 | 24 | - | 47 | 33 | 16 | 48 | M14 x 2.0P | 1 | 1.40 |

| 5011-653-016-150 | BT40xSLN16-150 | 215.4 | 150 | 24 | - | 47 | 120 | 16 | 48 | M14 x 2.0P | 1 | 1.60 |

| 5011-653-018-063 | BT40xSLN18-63 | 128.4 | 63 | 24 | - | 44 | 33 | 18 | 50 | M14 x 2.0P | 1 | 1.65 |

| 5011-653-020-063 | BT40xSLN20-63 | 128.4 | 63 | 25 | - | 49 | 33 | 20 | 52 | M16 x 2.0P | 1 | 1.40 |

| 5011-653-025-100 | BT40xSLN25-100 | 165.4 | 100 | 24 | 25 | 58 | 73 | 25 | 65 | M18 x 2.0P | 2 | 2.50 |

| 5011-653-032-100 | BT40xSLN32-100 | 165.4 | 100 | 24 | 28 | 63 | 73 | 32 | 72 | M20 x 2.0P | 2 | 2.75 |

| 5012-653-006-063 | BT50xSLN6-63 | 164.8 | 63 | 18 | - | 35 | 20 | 6 | 25 | M6 x 1.0P | 1 | 3.80 |

| 5012-653-008-063 | BT50xSLN8-63 | 164.8 | 63 | 18 | - | 39 | 20 | 8 | 28 | M8 x 1.25P | 1 | 3.80 |

| 5012-653-010-063 | BT50xSLN10-63 | 164.8 | 63 | 20 | - | 39 | 22 | 10 | 35 | M10 x 1.5P | 1 | 3.00 |

| 5012-653-012-080 | BT50xSLN12-80 | 181.8 | 80 | 22.5 | - | 44 | 39 | 12 | 42 | M12 x 1.75P | 1 | 4.00 |

| 5012-653-016-080 | BT50xSLN16-80 | 181.8 | 80 | 24 | - | 47 | 32 | 16 | 48 | M14 x 2.0P | 1 | 4.40 |

| 5012-653-020-080 | BT50xSLN20-80 | 181.8 | 80 | 25 | - | 49 | 37 | 20 | 52 | M16 x 2.0P | 1 | 4.40 |

| 5012-653-025-100 | BT50xSLN25-100 | 201.8 | 100 | 24 | 25 | 58 | 59 | 25 | 65 | M18 x 2.0P | 2 | 5.10 |

| 5012-653-032-105 | BT50xSLN32-105 | 206.8 | 105 | 24 | 28 | 63 | 64 | 32 | 72 | M20 x 2.0P | 2 | 5.20 |

| 5012-653-040-115 | BT50xSLN40-115 | 216.8 | 115 | 30 | 32 | 75 | 74 | 40 | 90 | M20 x 2.0P | 2 | 6.70 |

| 5012-653-040-120 | BT50xSLN40-120 | 221.8 | 120 | 30 | 32 | 75 | 79 | 40 | 90 | M20 x 2.0P | 2 | 6.70 |

| 5012-653-042-120 | BT50xSLN42-120 | 221.8 | 120 | 30 | 32 | 75 | 79 | 42 | 90 | M20 x 2.0P | 2 | 6.70 |

| 5012-653-050-120 | BT50xSLN50-120 | 221.8 | 120 | 35 | 35 | 78 | 82 | 50 | 98 | M24 x 2.0P | 2 | 7.16 |

| 5012-653-A96-472 | BT50xSLN50.8-120 | 221.8 | 120 | 33.1 | 28.58 | 80 | 82 | 50.8 | 99 | M20 x 2.0P | 2 | 6.80 |

| 5012-677-A96-472 | BT50xSLN50.8-120 | 221.8 | 120 | 33.1 | 28.58 | 75 | 81 | 50.8 | 95 | M20 x 2.0P | 3 | 7.20 |

| 5012-677-063-120 | BT50xSLN63-120 | 221.8 | 120 | 33.1 | 28.58 | 80 | 82 | 63 | 125 | M16 x 2.0P | 3 | 6.60 |

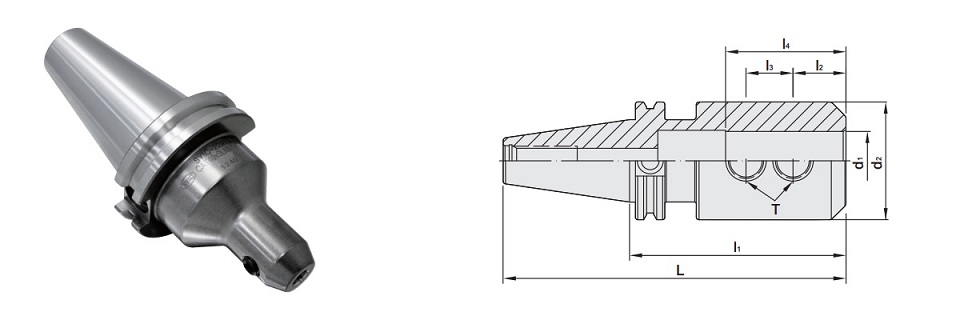

BT/SLN SIDE LOCK END MILL HOLDER (JIS TYPE)

_figure.jpg)

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | l5 | d1 | d2 | d3 | T | Fig. | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5011-654-006-075 | BT40xSLN6-75JIS | 140.4 | 75 | 12 | 10 | 35 | 45 | 6 | 25 | - | M6 x 1.0P | 1 | 1.20 |

| 5011-654-006-150 | BT40xSLN6-150JIS | 215.4 | 150 | 12 | 10 | 35 | 113 | 6 | 25 | 30 | M6 x 1.0P | 2 | 1.50 |

| 5011-654-008-075 | BT40xSLN8-75JIS | 140.4 | 75 | 14 | 12 | 35 | 45 | 8 | 28 | - | M8 x 1.25P | 1 | 1.20 |

| 5011-654-008-150 | BT40xSLN8-150JIS | 215.4 | 150 | 14 | 12 | 35 | 113 | 8 | 28 | 33 | M8 x 1.25P | 2 | 1.50 |

| 5011-654-010-075 | BT40xSLN10-75JIS | 140.4 | 75 | 15 | 14 | 39 | 45 | 10 | 35 | - | M10 x 1.5P | 1 | 1.40 |

| 5011-654-010-150 | BT40xSLN10-150JIS | 215.4 | 150 | 15 | 14 | 39 | 118 | 10 | 35 | 40 | M10 x 1.5P | 2 | 1.50 |

| 5011-654-012-075 | BT40xSLN12-75JIS | 140.4 | 75 | 20 | 16 | 44 | 45 | 12 | 42 | - | M10 x 1.5P | 1 | 1.50 |

| 5011-654-012-150 | BT40xSLN12-150JIS | 215.4 | 150 | 20 | 16 | 44 | 118 | 12 | 42 | 47 | M10 x 1.5P | 2 | 1.70 |

| 5011-654-016-075 | BT40xSLN16-75JIS | 140.4 | 75 | 22 | 18 | 47 | 45 | 16 | 48 | - | M10 x 1.5P | 1 | 1.60 |

| 5011-654-016-150 | BT40xSLN16-150JIS | 215.4 | 150 | 22 | 18 | 47 | 120 | 16 | 48 | 53 | M10 x 1.5P | 2 | 1.70 |

| 5011-654-020-090 | BT40xSLN20-90JIS | 155.4 | 90 | 25 | 20 | 55 | 60 | 20 | 50 | - | M12 x 1.75P | 1 | 1.75 |

| 5011-654-020-150 | BT40xSLN20-150JIS | 215.4 | 150 | 25 | 20 | 55 | 120 | 20 | 52 | 57 | M12 x 1.75P | 2 | 1.80 |

| 5011-654-025-090 | BT40xSLN25-90JIS | 155.4 | 90 | 24 | 25 | 58 | 60 | 25 | 50 | - | M12 x 1.75P | 1 | 1.70 |

| 5011-654-032-100 | BT40xSLN32-100JIS | 165.4 | 100 | 24 | 28 | 63 | 73 | 32 | 60 | - | M16 x 2.0P | 1 | 2.10 |

| 5012-654-006-075 | BT50xSLN6-75JIS | 176.8 | 75 | 12 | 10 | 35 | 27 | 6 | 25 | - | M6 x 1.0P | 1 | 3.90 |

| 5012-654-008-075 | BT50xSLN8-75JIS | 176.8 | 75 | 14 | 12 | 35 | 27 | 8 | 28 | - | M8 x 1.25P | 1 | 3.90 |

| 5012-654-010-075 | BT50xSLN10-75JIS | 176.8 | 75 | 15 | 14 | 39 | 32 | 10 | 35 | - | M10 x 1.5P | 1 | 3.90 |

| 5012-654-012-090 | BT50xSLN12-90JIS | 191.8 | 90 | 20 | 16 | 44 | 42 | 12 | 42 | - | M10 x 1.5P | 1 | 3.90 |

| 5012-654-012-165 | BT50xSLN12-165JIS | 266.8 | 165 | 20 | 16 | 44 | 124 | 12 | 42 | 47 | M10 x 1.5P | 2 | 5.00 |

| 5012-654-016-090 | BT50xSLN16-90JIS | 191.8 | 90 | 22 | 18 | 47 | 42 | 16 | 48 | - | M10 x 1.5P | 1 | 3.90 |

| 5012-654-016-150 | BT50xSLN16-150JIS | 251.8 | 150 | 22 | 18 | 47 | 102 | 16 | 48 | 53 | M10 x 1.5P | 2 | 4.98 |

| 5012-654-016-165 | BT50xSLN16-165JIS | 266.8 | 165 | 22 | 18 | 47 | 117 | 16 | 48 | 53 | M10 x 1.5P | 2 | 5.00 |

| 5012-654-020-090 | BT50xSLN20-90JIS | 191.8 | 90 | 25 | 20 | 55 | 49 | 20 | 50 | - | M12 x 1.75P | 1 | 4.50 |

| 5012-654-020-150 | BT50xSLN20-150JIS | 251.8 | 150 | 25 | 20 | 55 | 102 | 20 | 50 | 57 | M12 x 1.75P | 2 | 5.98 |

| 5012-654-020-165 | BT50xSLN20-165JIS | 266.8 | 165 | 25 | 20 | 55 | 117 | 20 | 50 | 57 | M12 x 1.75P | 2 | 6.00 |

| 5012-654-020-210 | BT50xSLN20-210JIS | 311.8 | 210 | 25 | 20 | 55 | 162 | 20 | 50 | 57 | M12 x 1.75P | 2 | 7.00 |

| 5012-654-025-100 | BT50xSLN25-100JIS | 201.8 | 100 | 24 | 25 | 58 | 59 | 25 | 50 | - | M12 x 1.75P | 1 | 4.58 |

| 5012-654-025-150 | BT50xSLN25-150JIS | 251.8 | 150 | 24 | 25 | 58 | 102 | 25 | 50 | 57 | M12 x 1.75P | 2 | 5.48 |

| 5012-654-025-165 | BT50xSLN25-165JIS | 266.8 | 165 | 24 | 25 | 58 | 117 | 25 | 50 | 57 | M12 x 1.75P | 2 | 5.50 |

| 5012-654-025-210 | BT50xSLN25-210JIS | 311.8 | 210 | 24 | 25 | 58 | 169 | 25 | 50 | 57 | M12 x 1.75P | 2 | 6.00 |

| 5012-654-025-250 | BT50xSLN25-250JIS | 351.8 | 250 | 24 | 25 | 58 | 202 | 25 | 50 | 60 | M12 x 1.75P | 2 | 7.00 |

| 5012-654-032-105 | BT50xSLN32-105JIS | 206.8 | 105 | 24 | 28 | 63 | 64 | 32 | 60 | - | M16 x 2.0P | 1 | 4.89 |

| 5012-654-032-150 | BT50xSLN32-150JIS | 251.8 | 150 | 24 | 28 | 63 | 102 | 32 | 50 | 60 | M16 x 2.0P | 2 | 7.48 |

| 5012-654-032-165 | BT50xSLN32-165JIS | 266.8 | 165 | 24 | 28 | 63 | 117 | 32 | 60 | 65 | M16 x 2.0P | 2 | 6.22 |

| 5012-654-032-210 | BT50xSLN32-210JIS | 311.8 | 210 | 24 | 28 | 63 | 162 | 32 | 50 | 60 | M16 x 2.0P | 2 | 6.34 |

| 5012-654-032-250 | BT50xSLN32-250JIS | 351.8 | 250 | 24 | 28 | 63 | 207 | 32 | 50 | 60 | M16 x 2.0P | 2 | 7.50 |

| 5012-654-032-300 | BT50xSLN32-300JIS | 401.8 | 300 | 24 | 28 | 63 | 257 | 32 | 60 | 65 | M16 x 2.0P | 2 | 8.00 |

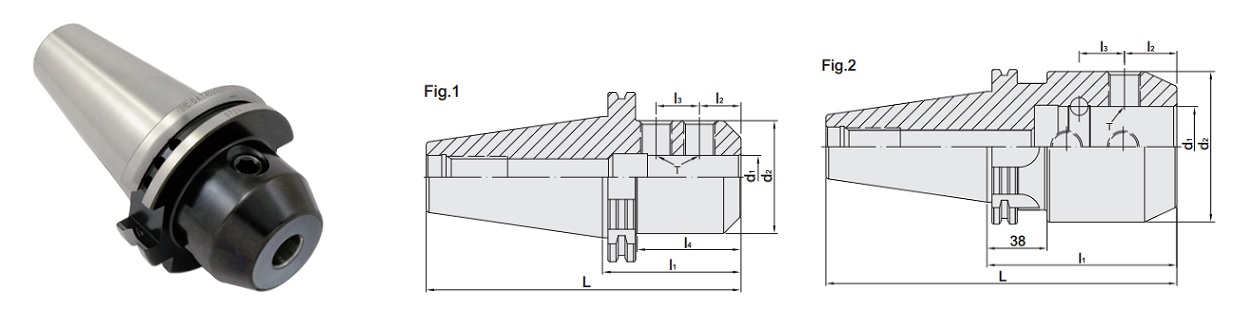

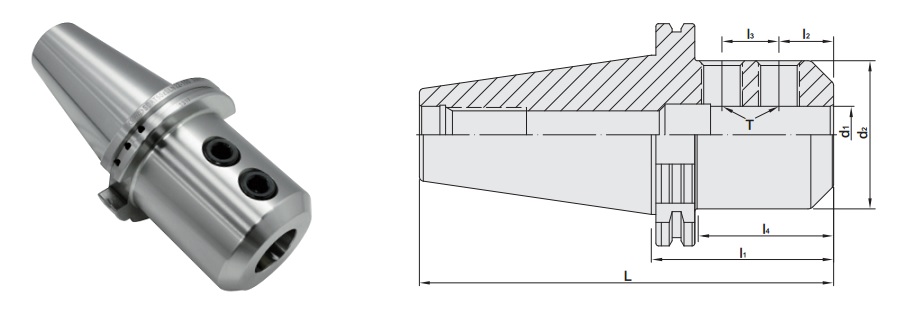

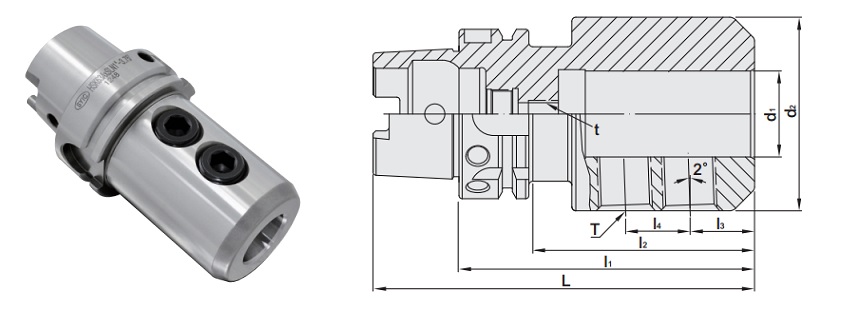

BT/SLN SIDE LOCK END MILL HOLDER (FID TYPE)

_figure.jpg)

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | l5 | d1 | d2 | T | Fig. | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5011-S35-006-050 | BT40xSLN6-50-FID | 115.4 | 50 | 18 | - | 35 | 20 | 6 | 25 | M6 x 1.0P | 1 | 1.10 |

| 5011-S35-006-150 | BT40xSLN6-150-FID | 215.4 | 150 | 18 | - | 35 | 113 | 6 | 25 | M6 x 1.0P | 1 | 1.32 |

| 5011-S35-008-050 | BT40xSLN8-50-FID | 115.4 | 50 | 18 | - | 35 | 20 | 8 | 28 | M8 x 1.25P | 1 | 1.10 |

| 5011-S35-008-150 | BT40xSLN8-150-FID | 215.4 | 150 | 18 | - | 35 | 113 | 8 | 28 | M8 x 1.25P | 1 | 1.30 |

| 5011-S35-010-063 | BT40xSLN10-63-FID | 128.4 | 63 | 20 | - | 39 | 33 | 10 | 35 | M10 x 1.5P | 1 | 1.25 |

| 5011-S35-010-150 | BT40xSLN10-150-FID | 215.4 | 150 | 20 | - | 39 | 113 | 10 | 35 | M10 x 1.5P | 1 | 1.40 |

| 5011-S35-012-063 | BT40xSLN12-63-FID | 128.4 | 63 | 22.5 | - | 44 | 33 | 12 | 42 | M12 x 1.75P | 1 | 1.30 |

| 5011-S35-012-150 | BT40xSLN12-150-FID | 215.4 | 150 | 22.5 | - | 44 | 116 | 12 | 42 | M12 x 1.75P | 1 | 1.53 |

| 5011-S35-016-063 | BT40xSLN16-63-FID | 128.4 | 63 | 24 | - | 47 | 33 | 16 | 48 | M14 x 2.0P | 1 | 1.40 |

| 5011-S35-016-150 | BT40xSLN16-150-FID | 215.4 | 150 | 24 | - | 47 | 120 | 16 | 48 | M14 x 2.0P | 1 | 1.60 |

| 5011-S35-018-063 | BT40xSLN18-63-FID | 128.4 | 63 | 24 | - | 44 | 33 | 18 | 50 | M14 x 2.0P | 1 | 1.65 |

| 5011-S35-020-063 | BT40xSLN20-63-FID | 128.4 | 63 | 25 | - | 49 | 33 | 20 | 52 | M16 x 2.0P | 1 | 1.40 |

| 5011-S35-025-100 | BT40xSLN25-100-FID | 165.4 | 100 | 24 | 25 | 58 | 73 | 25 | 65 | M18 x 2.0P | 2 | 2.50 |

| 5011-S35-032-100 | BT40xSLN32-100-FID | 165.4 | 100 | 24 | 28 | 63 | 73 | 32 | 72 | M20 x 2.0P | 2 | 2.75 |

| 5012-S35-006-063 | BT50xSLN6-63-FID | 164.8 | 63 | 18 | - | 35 | 20 | 6 | 25 | M6 x 1.0P | 1 | 3.80 |

| 5012-S35-008-063 | BT50xSLN8-63-FID | 164.8 | 63 | 18 | - | 39 | 20 | 8 | 28 | M8 x 1.25P | 1 | 3.80 |

| 5012-S35-010-063 | BT50xSLN10-63-FID | 164.8 | 63 | 20 | - | 39 | 22 | 10 | 35 | M10 x 1.5P | 1 | 3.00 |

| 5012-S35-012-080 | BT50xSLN12-80-FID | 181.8 | 80 | 22.5 | - | 44 | 39 | 12 | 42 | M12 x 1.75P | 1 | 4.00 |

| 5012-S35-016-080 | BT50xSLN16-80-FID | 181.8 | 80 | 24 | - | 47 | 32 | 16 | 48 | M14 x 2.0P | 1 | 4.40 |

| 5012-S35-020-080 | BT50xSLN20-80-FID | 181.8 | 80 | 25 | - | 49 | 37 | 20 | 52 | M16 x 2.0P | 1 | 4.40 |

| 5012-S35-025-100 | BT50xSLN25-100-FID | 201.8 | 100 | 24 | 25 | 58 | 59 | 25 | 65 | M18 x 2.0P | 2 | 5.10 |

| 5012-S35-032-105 | BT50xSLN32-105-FID | 206.8 | 105 | 24 | 28 | 63 | 64 | 32 | 72 | M20 x 2.0P | 2 | 5.20 |

| 5012-S35-040-115 | BT50xSLN40-115-FID | 216.8 | 115 | 30 | 32 | 75 | 74 | 40 | 90 | M20 x 2.0P | 2 | 6.70 |

| 5012-S35-040-120 | BT50xSLN40-120-FID | 221.8 | 120 | 30 | 32 | 75 | 79 | 40 | 90 | M20 x 2.0P | 2 | 6.70 |

| 5012-S35-042-120 | BT50xSLN42-120-FID | 221.8 | 120 | 30 | 32 | 75 | 79 | 42 | 90 | M20 x 2.0P | 2 | 6.70 |

| 5012-S35-050-120 | BT50xSLN50-120-FID | 221.8 | 120 | 35 | 35 | 78 | 82 | 50 | 98 | M24 x 2.0P | 2 | 7.16 |

| 5012-S35-A96-472 | BT50xSLN50.8-120-FID | 221.8 | 120 | 33.1 | 28.58 | 80 | 82 | 50.8 | 99 | M20 x 2.0P | 2 | 6.80 |

| 5012-S81-A96-472 | BT50xSLN50.8-120-FID | 221.8 | 120 | 33.1 | 28.58 | 75 | 81 | 50.8 | 95 | M20 x 2.0P | 3 | 7.20 |

| 5012-S81-063-120 | BT50xSLN63-120-FID | 221.8 | 120 | 33.1 | 28.58 | 80 | 82 | 63 | 125 | M16 x 2.0P | 3 | 6.60 |

BT/SLN SIDE LOCK END MILL HOLDER (JIS-FID TYPE)

_figure.jpg)

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | l5 | d1 | d2 | d3 | T | Fig. | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5011-S34-006-075 | BT40xSLN6-75JIS-FID | 140.4 | 75 | 12 | 10 | 35 | 45 | 6 | 25 | - | M6 x 1.0P | 1 | 1.20 |

| 5011-S34-006-150 | BT40xSLN6-150JIS-FID | 215.4 | 150 | 12 | 10 | 35 | 113 | 6 | 25 | 30 | M6 x 1.0P | 2 | 1.50 |

| 5011-S34-008-075 | BT40xSLN8-75JIS-FID | 140.4 | 75 | 14 | 12 | 35 | 45 | 8 | 28 | - | M8 x 1.25P | 1 | 1.20 |

| 5011-S34-008-150 | BT40xSLN8-150JIS-FID | 215.4 | 150 | 14 | 12 | 35 | 113 | 8 | 28 | 33 | M8 x 1.25P | 2 | 1.50 |

| 5011-S34-010-075 | BT40xSLN10-75JIS-FID | 140.4 | 75 | 15 | 14 | 39 | 45 | 10 | 35 | - | M10 x 1.5P | 1 | 1.40 |

| 5011-S34-010-150 | BT40xSLN10-150JIS-FID | 215.4 | 150 | 15 | 14 | 39 | 118 | 10 | 35 | 40 | M10 x 1.5P | 2 | 1.50 |

| 5011-S34-012-075 | BT40xSLN12-75JIS-FID | 140.4 | 75 | 20 | 16 | 44 | 45 | 12 | 42 | - | M10 x 1.5P | 1 | 1.50 |

| 5011-S34-012-150 | BT40xSLN12-150JIS-FID | 215.4 | 150 | 20 | 16 | 44 | 118 | 12 | 42 | 47 | M10 x 1.5P | 2 | 1.70 |

| 5011-S34-016-075 | BT40xSLN16-75JIS-FID | 140.4 | 75 | 22 | 18 | 47 | 45 | 16 | 48 | - | M10 x 1.5P | 1 | 1.60 |

| 5011-S34-016-150 | BT40xSLN16-150JIS-FID | 215.4 | 150 | 22 | 18 | 47 | 120 | 16 | 48 | 53 | M10 x 1.5P | 2 | 1.70 |

| 5011-S34-020-090 | BT40xSLN20-90JIS-FID | 155.4 | 90 | 25 | 20 | 55 | 60 | 20 | 50 | - | M12 x 1.75P | 1 | 1.75 |

| 5011-S34-020-150 | BT40xSLN20-150JIS-FID | 215.4 | 150 | 25 | 20 | 55 | 120 | 20 | 52 | 57 | M12 x 1.75P | 2 | 1.80 |

| 5011-S34-025-090 | BT40xSLN25-90JIS-FID | 155.4 | 90 | 24 | 25 | 58 | 60 | 25 | 50 | - | M12 x 1.75P | 1 | 1.70 |

| 5011-S34-032-100 | BT40xSLN32-100JIS-FID | 165.4 | 100 | 24 | 28 | 63 | 73 | 32 | 60 | - | M16 x 2.0P | 1 | 2.10 |

| 5012-S34-006-075 | BT50xSLN6-75JIS-FID | 176.8 | 75 | 12 | 10 | 35 | 27 | 6 | 25 | - | M6 x 1.0P | 1 | 3.90 |

| 5012-S34-008-075 | BT50xSLN8-75JIS-FID | 176.8 | 75 | 14 | 12 | 35 | 27 | 8 | 28 | - | M8 x 1.25P | 1 | 3.90 |

| 5012-S34-010-075 | BT50xSLN10-75JIS-FID | 176.8 | 75 | 15 | 14 | 39 | 32 | 10 | 35 | - | M10 x 1.5P | 1 | 3.90 |

| 5012-S34-012-090 | BT50xSLN12-90JIS-FID | 191.8 | 90 | 20 | 16 | 44 | 42 | 12 | 42 | - | M10 x 1.5P | 1 | 3.90 |

| 5012-S34-012-165 | BT50xSLN12-165JIS-FID | 266.8 | 165 | 20 | 16 | 44 | 124 | 12 | 42 | 47 | M10 x 1.5P | 2 | 5.00 |

| 5012-S34-016-090 | BT50xSLN16-90JIS-FID | 191.8 | 90 | 22 | 18 | 47 | 42 | 16 | 48 | - | M10 x 1.5P | 1 | 3.90 |

| 5012-S34-016-165 | BT50xSLN16-165JIS-FID | 266.8 | 165 | 22 | 18 | 47 | 117 | 16 | 48 | 53 | M10 x 1.5P | 2 | 5.00 |

| 5012-S34-020-090 | BT50xSLN20-90JIS-FID | 191.8 | 90 | 25 | 20 | 55 | 49 | 20 | 50 | - | M12 x 1.75P | 1 | 4.50 |

| 5012-S34-020-165 | BT50xSLN20-165JIS-FID | 266.8 | 165 | 25 | 20 | 55 | 117 | 20 | 50 | 57 | M12 x 1.75P | 2 | 6.00 |

| 5012-S34-020-210 | BT50xSLN20-210JIS-FID | 311.8 | 210 | 25 | 20 | 55 | 162 | 20 | 50 | 57 | M12 x 1.75P | 2 | 7.00 |

| 5012-S34-025-100 | BT50xSLN25-100JIS-FID | 201.8 | 100 | 24 | 25 | 58 | 59 | 25 | 50 | - | M12 x 1.75P | 1 | 4.58 |

| 5012-S34-025-165 | BT50xSLN25-165JIS-FID | 266.8 | 165 | 24 | 25 | 58 | 117 | 25 | 50 | 57 | M12 x 1.75P | 2 | 5.50 |

| 5012-S34-025-210 | BT50xSLN25-210JIS-FID | 311.8 | 210 | 24 | 25 | 58 | 169 | 25 | 50 | 57 | M12 x 1.75P | 2 | 6.00 |

| 5012-S34-025-250 | BT50xSLN25-250JIS-FID | 351.8 | 250 | 24 | 25 | 58 | 202 | 25 | 50 | 60 | M12 x 1.75P | 2 | 7.00 |

| 5012-S34-032-105 | BT50xSLN32-105JIS-FID | 206.8 | 105 | 24 | 28 | 63 | 64 | 32 | 60 | - | M16 x 2.0P | 1 | 4.89 |

| 5012-S34-032-165 | BT50xSLN32-165JIS-FID | 266.8 | 165 | 24 | 28 | 63 | 117 | 32 | 60 | 65 | M16 x 2.0P | 2 | 6.22 |

| 5012-S34-032-210 | BT50xSLN32-210JIS-FID | 311.8 | 210 | 24 | 28 | 63 | 162 | 32 | 50 | 60 | M16 x 2.0P | 2 | 6.34 |

| 5012-S34-032-250 | BT50xSLN32-250JIS-FID | 351.8 | 250 | 24 | 28 | 63 | 207 | 32 | 50 | 60 | M16 x 2.0P | 2 | 7.50 |

| 5012-S34-032-300 | BT50xSLN32-300JIS-FID | 401.8 | 300 | 24 | 28 | 63 | 257 | 32 | 60 | 65 | M16 x 2.0P | 2 | 8.00 |

CAT/SLN SIDE LOCK END MILL HOLDER

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | d1 | d2 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|

| 5031-653-A08-238 | CAT40xSLN1/8"-2.375" | 5.062 | 2.375 | 0.37 | - | 0.787 | 0.125 | 0.69 | 6# - 32 | 1.15 |

| 5031-653-A12-250 | CAT40xSLN3/16"-2.5" | 5.187 | 2.5 | 0.562 | - | 0.984 | 0.1875 | 0.69 | 8# - 32 | 1.20 |

| 5031-653-A16-300 | CAT40xSLN1/4"-3" | 5.687 | 3 | 0.63 | - | 1.38 | 0.25 | 0.78 | 1/4 - 28 | 1.15 |

| 5031-653-A20-300 | CAT40xSLN5/16"-3" | 5.687 | 3 | 0.6 | - | 1.38 | 0.3125 | 0.88 | 5/16 - 24 | 1.20 |

| 5031-653-A24-300 | CAT40xSLN3/8"-3" | 5.687 | 3 | 0.75 | - | 1.535 | 0.375 | 1 | 3/8 - 24 | 1.18 |

| 5031-653-A32-300 | CAT40xSLN1/2"-3" | 5.687 | 3 | 0.875 | - | 1.732 | 0.5 | 1.25 | 7/16 - 20 | 1.40 |

| 5031-653-A40-300 | CAT40xSLN5/8"-3" | 5.687 | 3 | 0.937 | - | 1.85 | 0.625 | 1.5 | 1/2 - 20 | 1.50 |

| 5031-653-A48-300 | CAT40xSLN3/4"-3" | 5.687 | 3 | 1 | - | 1.929 | 0.75 | 1.75 | 5/8 - 18 | 1.65 |

| 5031-653-A48-350 | CAT40xSLN3/4"-3.5" | 6.187 | 3.5 | 1 | - | 1.929 | 0.75 | 1.75 | 5/8 - 18 | 1.70 |

| 5031-653-A56-350 | CAT40xSLN7/8"-3.5" | 6.187 | 3.5 | 1.063 | 0.875 | 2.36 | 0.875 | 1.88 | 5/8 - 18 | 2.55 |

| 5031-653-A64-400 | CAT40xSLN1"-4" | 6.687 | 4 | 1.125 | 1 | 2.56 | 1 | 2 | 3/4 - 16 | 2.80 |

| 5031-653-A72-460 | CAT40xSLN1-1/4"-4.6" | 7.287 | 4.6 | 1.125 | 1 | 2.56 | 1.25 | 2.5 | 3/4 - 16 | 2.90 |

| 5031-653-A80-450 | CAT40xSLN1-1/2"-4.5" | 7.187 | 4.5 | 1.125 | 1 | 2.56 | 1.5 | 2.5 | 3/4 - 16 | 3.20 |

| 5032-653-A16-400 | CAT50xSLN1/4"-4" | 8 | 4 | 0.63 | - | 1.378 | 0.25 | 0.78 | 1/4 - 28 | 3.95 |

| 5032-653-A20-400 | CAT50xSLN5/16"-4" | 8 | 4 | 0.6 | - | 1.378 | 0.3125 | 0.88 | 5/16 - 24 | 3.95 |

| 5032-653-A24-400 | CAT50xSLN3/8"-4" | 8 | 4 | 0.75 | - | 1.535 | 0.375 | 1 | 3/8 - 24 | 4.00 |

| 5032-653-A32-400 | CAT50xSLN1/2"-4" | 8 | 4 | 0.875 | - | 1.732 | 0.5 | 1.25 | 7/16 - 20 | 4.15 |

| 5032-653-A40-400 | CAT50xSLN5/8"-4" | 8 | 4 | 0.937 | - | 1.85 | 0.625 | 1.5 | 1/2 - 20 | 4.30 |

| 5032-653-A48-400 | CAT50xSLN3/4"-4" | 8 | 4 | 1 | - | 1.929 | 0.75 | 1.75 | 5/8 - 18 | 4.35 |

| 5032-653-A56-400 | CAT50xSLN7/8"-4" | 8 | 4 | 1.063 | 0.875 | 2.362 | 0.875 | 1.88 | 5/8 - 18 | 5.30 |

| 5032-653-A64-400 | CAT50xSLN1"-4" | 8 | 4 | 1.125 | 1 | 2.56 | 1 | 2 | 3/4 - 16 | 5.50 |

| 5032-653-A72-400 | CAT50xSLN1-1/4"-4" | 8 | 4 | 1.125 | 1 | 2.756 | 1.25 | 2.5 | 3/4 - 16 | 5.65 |

| 5032-653-A72-460 | CAT50xSLN1-1/4"-4.6" | 8.6 | 4.6 | 1.125 | 1 | 2.756 | 1.25 | 2.5 | 3/4 - 16 | 5.70 |

| 5032-653-A80-460 | CAT50xSLN1-1/2"-4.6" | 8.6 | 4.6 | 1.125 | 1 | 2.756 | 1.5 | 2.5 | 3/4 - 16 | 5.70 |

| 5032-653-A96-600 | CAT50xSLN2"-6" | 10 | 6 | 1.41 | 1.5 | 3.347 | 2 | 3.75 | 1 - 14 | 5.90 |

DAT/SLN SIDE LOCK END MILL HOLDER

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | d1 | d2 | T | Fig. | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 5050-653-006-050 | DAT30xSLN6-50 | 97.8 | 50 | 18 | - | 25 | 6 | 25 | M6 x 1.0P | 1 | 0.73 |

| 5050-653-008-050 | DAT30xSLN8-50 | 97.8 | 50 | 18 | - | 27 | 8 | 28 | M8 x 1.25P | 1 | 0.80 |

| 5050-653-010-050 | DAT30xSLN10-50 | 97.8 | 50 | 20 | - | 27 | 10 | 35 | M10 x 1.5P | 1 | 0.90 |

| 5050-653-012-050 | DAT30xSLN12-50 | 97.8 | 50 | 22.5 | - | 29 | 12 | 42 | M12 x 1.75P | 1 | 0.90 |

| 5050-653-016-063 | DAT30xSLN16-63 | 110.8 | 63 | 24 | - | 43 | 16 | 45 | M14 x 2.0P | 1 | 1.10 |

| 5051-653-006-050 | DAT40xSLN6-50 | 118.4 | 50 | 18 | - | 27 | 6 | 25 | M6 x 1.0P | 1 | 0.85 |

| 5051-653-008-050 | DAT40xSLN8-50 | 118.4 | 50 | 18 | - | 27 | 8 | 28 | M8 x 1.25P | 1 | 1.00 |

| 5051-653-010-050 | DAT40xSLN10-50 | 118.4 | 50 | 20 | - | 27 | 10 | 35 | M10 x 1.5P | 1 | 1.10 |

| 5051-653-012-050 | DAT40xSLN12-50 | 118.4 | 50 | 22.5 | - | 30 | 12 | 42 | M12 x 1.75P | 1 | 1.15 |

| 5051-653-014-063 | DAT40xSLN14-63 | 131.4 | 63 | 22.5 | - | 40.9 | 14 | 44 | M12 x 1.75P | 1 | 1.30 |

| 5051-653-016-063 | DAT40xSLN16-63 | 131.4 | 63 | 24 | - | 43 | 16 | 48 | M14 x 2.0P | 1 | 1.40 |

| 5051-653-018-063 | DAT40xSLN18-63 | 131.4 | 63 | 24 | - | 43.1 | 18 | 50 | M14 x 2.0P | 1 | 1.26 |

| 5051-653-020-063 | DAT40xSLN20-63 | 131.4 | 63 | 25 | - | 43 | 20 | 52 | M16 x 2.0P | 1 | 1.30 |

| 5051-653-025-100 | DAT40xSLN25-100 | 168.4 | 100 | 24 | 25 | 65 | 25 | 65 | M18 x 2.0P | 1 | 2.40 |

| 5051-653-032-100 | DAT40xSLN32-100 | 168.4 | 100 | 24 | 28 | 65 | 32 | 72 | M20 x 2.0P | 1 | 2.70 |

| 5052-653-006-063 | DAT50xSLN6-63 | 164.75 | 63 | 18 | - | 33 | 6 | 25 | M6 x 1.0P | 1 | 3.10 |

| 5052-653-008-063 | DAT50xSLN8-63 | 164.75 | 63 | 18 | - | 33 | 8 | 28 | M8 x 1.25P | 1 | 3.10 |

| 5052-653-010-063 | DAT50xSLN10-63 | 164.75 | 63 | 20 | - | 33 | 10 | 35 | M10 x 1.5P | 1 | 3.30 |

| 5052-653-012-063 | DAT50xSLN12-63 | 164.75 | 63 | 22.5 | - | 40 | 12 | 42 | M12 x 1.75P | 1 | 3.50 |

| 5052-653-014-063 | DAT50xSLN14-63 | 164.75 | 63 | 22.5 | - | 40.9 | 14 | 44 | M12 x 1.75P | 1 | 3.50 |

| 5052-653-016-063 | DAT50xSLN16-63 | 164.75 | 63 | 24 | - | 40 | 16 | 48 | M14 x 2.0P | 1 | 3.45 |

| 5052-653-018-063 | DAT50xSLN18-63 | 164.75 | 63 | 24 | - | 38.9 | 18 | 50 | M14 x 2.0P | 1 | 2.99 |

| 5052-653-020-063 | DAT50xSLN20-63 | 164.75 | 63 | 25 | - | 40 | 20 | 52 | M16 x 2.0P | 1 | 3.50 |

| 5052-653-025-080 | DAT50xSLN25-80 | 181.75 | 80 | 24 | 25 | 59 | 25 | 65 | M18 x 2.0P | 1 | 4.20 |

| 5052-653-032-100 | DAT50xSLN32-100 | 201.75 | 100 | 24 | 28 | 78 | 32 | 72 | M20 x 2.0P | 1 | 5.00 |

| 5052-653-040-100 | DAT50xSLN40-100 | 201.75 | 100 | 30 | 32 | 80 | 40 | 90 | M20 x 2.0P | 1 | 5.60 |

| 5052-653-042-100 | DAT50xSLN42-100 | 201.75 | 100 | 30 | 32 | 80 | 42 | 90 | M20 x 2.0P | 1 | 5.70 |

| 5052-653-050-125 | DAT50xSLN50-125 | 226.75 | 125 | 35 | 35 | 85 | 50 | 100 | M24 x 2.0P | 1 | 5.90 |

| 5052-677-A96-472 | DAT50xSLN50.8-120 | 221.75 | 120 | 33.1 | 28.58 | 82 | 50.8 | 95 | M20 x 2.0P | 2 | 5.80 |

| 5052-653-063-150 | DAT50xSLN63-150 | 251.75 | 150 | 40 | 40 | 112 | 63 | 125 | M20 x 2.0P | 1 | 6.20 |

| 5052-677-063-150 | DAT50xSLN63-150 | 251.75 | 150 | 40 | 24 | 112 | 63 | 125 | M16 x 2.0P | 2 | 6.20 |

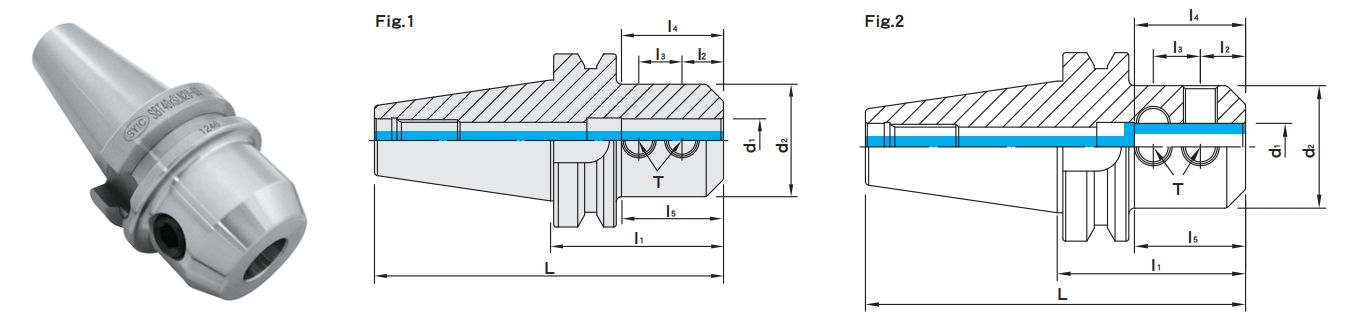

DualDRIVE+ SBT/SLN SIDE LOCK END MILL HOLDER

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | l5 | d1 | d2 | T | Fig | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5025-653-006-060 | SBT30xSLN6-60 | 108.4 | 60 | 18 | - | 35 | 33 | 6 | 25 | M6 x 1.0P | 1 | 0.55 |

| 5025-653-008-060 | SBT30xSLN8-60 | 108.4 | 60 | 18 | - | 35 | 33 | 8 | 28 | M8 x 1.25P | 1 | 0.60 |

| 5025-653-010-060 | SBT30xSLN10-60 | 108.4 | 60 | 20 | - | 39 | 35 | 10 | 35 | M10 x 1.5P | 1 | 0.70 |

| 5025-653-012-060 | SBT30xSLN12-60 | 108.4 | 60 | 22.5 | - | 44 | 36 | 12 | 42 | M12 x 1.75P | 1 | 0.75 |

| 5025-653-016-075 | SBT30xSLN16-75 | 123.4 | 75 | 24 | - | 47 | 53 | 16 | 48 | M14 x 2.0P | 1 | 1.05 |

| 5025-653-020-075 | SBT30xSLN20-75 | 123.4 | 75 | 25 | - | 49 | 53 | 20 | 52 | M16 x 2.0P | 1 | 1.10 |

| 5025-653-025-090 | SBT30xSLN25-90 | 138.4 | 90 | 24 | 25 | 58 | 68 | 25 | 65 | M18 x 2.0P | 1 | 1.70 |

| 5026-653-006-050 | SBT40xSLN6-50 | 115.4 | 50 | 18 | - | 35 | 20 | 6 | 25 | M6 x 1.0P | 1 | 1.10 |

| 5026-653-006-150 | SBT40xSLN6-150 | 215.4 | 150 | 18 | - | 35 | 113 | 6 | 25 | M6 x 1.0P | 1 | 1.32 |

| 5026-653-008-050 | SBT40xSLN8-50 | 115.4 | 50 | 18 | - | 35 | 20 | 8 | 28 | M8 x 1.25P | 1 | 1.10 |

| 5026-653-008-150 | SBT40xSLN8-150 | 215.4 | 150 | 18 | - | 35 | 113 | 8 | 28 | M8 x 1.25P | 1 | 1.30 |

| 5026-653-010-063 | SBT40xSLN10-63 | 128.4 | 63 | 20 | - | 39 | 33.5 | 10 | 35 | M10 x 1.5P | 1 | 1.25 |

| 5026-653-010-150 | SBT40xSLN10-150 | 215.4 | 150 | 20 | - | 39 | 113 | 10 | 35 | M10 x 1.5P | 1 | 1.40 |

| 5026-653-012-063 | SBT40xSLN12-63 | 128.4 | 63 | 22.5 | - | 44 | 33.5 | 12 | 42 | M12 x 1.75P | 1 | 1.30 |

| 5026-653-012-150 | SBT40xSLN12-150 | 215.4 | 150 | 22.5 | - | 44 | 116 | 12 | 42 | M12 x 1.75P | 1 | 1.53 |

| 5026-653-016-063 | SBT40xSLN16-63 | 128.4 | 63 | 24 | - | 47 | 33.5 | 16 | 48 | M14 x 2.0P | 1 | 1.40 |

| 5026-653-016-150 | SBT40xSLN16-150 | 215.4 | 150 | 24 | - | 47 | 120 | 16 | 48 | M14 x 2.0P | 1 | 1.60 |

| 5026-653-018-063 | SBT40xSLN18-63 | 128.4 | 63 | 24 | - | 44 | 33 | 18 | 50 | M14 x 2.0P | 1 | 1.65 |

| 5026-653-020-063 | SBT40xSLN20-63 | 128.4 | 63 | 25 | - | 49 | 33 | 20 | 52 | M16 x 2.0P | 1 | 1.40 |

| 5026-653-025-100 | SBT40xSLN25-100 | 165.4 | 100 | 24 | 25 | 58 | 73 | 25 | 65 | M18 x 2.0P | 1 | 2.50 |

| 5026-653-032-100 | SBT40xSLN32-100 | 165.4 | 100 | 24 | 28 | 63 | 73 | 32 | 72 | M20 x 2.0P | 1 | 2.75 |

| 5027-653-006-063 | SBT50xSLN6-63 | 164.8 | 63 | 18 | - | 35 | 20 | 6 | 25 | M6 x 1.0P | 1 | 3.80 |

| 5027-653-008-063 | SBT50xSLN8-63 | 164.8 | 63 | 18 | - | 39 | 20 | 8 | 28 | M8 x 1.25P | 1 | 3.80 |

| 5027-653-010-063 | SBT50xSLN10-63 | 164.8 | 63 | 20 | - | 39 | 22 | 10 | 35 | M10 x 1.5P | 1 | 3.00 |

| 5027-653-012-080 | SBT50xSLN12-80 | 181.8 | 80 | 22.5 | - | 44 | 39 | 12 | 42 | M12 x 1.75P | 1 | 4.00 |

| 5027-653-016-080 | SBT50xSLN16-80 | 181.8 | 80 | 24 | - | 47 | 37 | 16 | 48 | M14 x 2.0P | 1 | 4.40 |

| 5027-653-020-080 | SBT50xSLN20-80 | 181.8 | 80 | 25 | - | 49 | 37 | 20 | 52 | M16 x 2.0P | 1 | 4.40 |

| 5027-653-025-100 | SBT50xSLN25-100 | 201.8 | 100 | 24 | 25 | 58 | 59 | 25 | 65 | M18 x 2.0P | 1 | 5.10 |

| 5027-653-032-105 | SBT50xSLN32-105 | 206.8 | 105 | 24 | 28 | 63 | 64 | 32 | 72 | M20 x 2.0P | 1 | 5.20 |

| 5027-653-040-115 | SBT50xSLN40-115 | 216.8 | 115 | 30 | 32 | 75 | 74 | 40 | 90 | M20 x 2.0P | 1 | 6.70 |

| 5027-653-040-120 | SBT50xSLN40-120 | 221.8 | 120 | 30 | 32 | 75 | 79 | 40 | 90 | M20 x 2.0P | 1 | 6.70 |

| 5027-653-042-120 | SBT50xSLN42-120 | 221.8 | 120 | 30 | 32 | 75 | 79 | 42 | 90 | M20 x 2.0P | 1 | 6.70 |

| 5027-653-050-120 | SBT50xSLN50-120 | 221.8 | 120 | 35 | 35 | 78 | 82 | 50 | 98 | M24 x 2.0P | 1 | 6.80 |

| 5027-653-A96-472 | SBT50xSLN50.8-120 | 221.8 | 120 | 33.1 | 28.58 | 80 | 82 | 50.8 | 99 | M20 x 2.0P | 1 | 6.80 |

| 5027-677-A96-472 | SBT50xSLN50.8-120 | 221.8 | 120 | 33.1 | 28.58 | 75 | 81 | 50.8 | 95 | M20 x 2.0P | 2 | 7.20 |

| INCHES | ||||||||||||

| 5025-653-A08-236 | SBT30xSLN1/8"-2.36" | 4.265 | 2.36 | 0.37 | - | 0.787 | 1.299 | 0.125 | 0.69 | #6 - 32 | 1 | 0.43 |

| 5025-653-A12-236 | SBT30xSLN3/16"-2.36" | 4.265 | 2.36 | 0.562 | - | 0.984 | 1.102 | 0.1875 | 0.69 | #8 - 32 | 1 | 0.44 |

| 5025-653-A16-236 | SBT30xSLN1/4"-2.36" | 4.265 | 2.36 | 0.629 | - | 1.378 | 1.181 | 0.25 | 0.78 | 1/4" - 28 | 1 | 0.45 |

| 5025-653-A20-236 | SBT30xSLN5/16"-2.36" | 4.265 | 2.36 | 0.6 | - | 1.378 | 1.181 | 0.3125 | 0.88 | 5/16" - 24 | 1 | 0.47 |

| 5025-653-A24-236 | SBT30xSLN3/8"-2.36" | 4.265 | 2.36 | 0.781 | - | 1.535 | 1.299 | 0.375 | 1 | 3/8" - 24 | 1 | 0.48 |

| 5025-653-A28-236 | SBT30xSLN7/16"-2.36" | 4.265 | 2.36 | 0.812 | - | 1.535 | 1.299 | 0.4375 | 1.13 | 7/16" - 20 | 1 | 0.51 |

| 5025-653-A32-236 | SBT30xSLN1/2"-2.36" | 4.265 | 2.36 | 0.875 | - | 1.732 | 1.378 | 0.5 | 1.25 | 7/16" - 20 | 1 | 0.54 |

| 5025-653-A40-236 | SBT30xSLN5/8"-2.36" | 4.265 | 2.36 | 0.937 | - | 1.85 | 1.417 | 0.625 | 1.5 | 1/2" - 20 | 1 | 0.61 |

| 5025-653-A40-300 | SBT30xSLN5/8"-3" | 4.906 | 3 | 0.937 | - | 1.85 | 2.094 | 0.625 | 1.5 | 1/2" - 20 | 1 | 0.73 |

| 5025-653-A48-236 | SBT30xSLN3/4"-2.36" | 4.265 | 2.36 | 1 | - | 1.929 | 1.494 | 0.75 | 1.75 | 5/8" - 18 | 1 | 0.65 |

| 5025-653-A64-400 | SBT30xSLN1"-4" | 5.906 | 4 | 1.125 | 1 | 2.559 | 2.818 | 1 | 2 | 3/4" - 16 | 1 | 1.15 |

| 5026-653-A08-250 | SBT40xSLN1/8"-2.5" | 5.075 | 2.5 | 0.37 | - | 0.787 | 1.24 | 0.125 | 0.69 | #6-32 | 1 | 1.01 |

| 5026-653-A08-400 | SBT40xSLN1/8"-4" | 6.575 | 4 | 0.37 | - | 0.787 | 2.543 | 0.125 | 0.69 | #6-32 | 1 | 1.06 |

| 5026-653-A12-250 | SBT40xSLN3/16"-2.5" | 5.075 | 2.5 | 0.562 | - | 0.984 | 1.24 | 0.1875 | 0.69 | #8-32 | 1 | 1.01 |

| 5026-653-A12-400 | SBT40xSLN3/16"-4" | 6.575 | 4 | 0.562 | - | 0.984 | 2.543 | 0.1875 | 0.69 | #8-32 | 1 | 1.02 |

| 5026-653-A16-250 | SBT40xSLN1/4"-2.5" | 5.075 | 2.5 | 0.63 | - | 1.378 | 1.122 | 0.25 | 0.78 | 1/4"-28 | 1 | 1.1 |

| 5026-653-A16-400 | SBT40xSLN1/4"-4" | 6.575 | 4 | 0.63 | - | 1.378 | 2.622 | 0.25 | 0.78 | 1/4"-28 | 1 | 1.04 |

| 5026-653-A20-250 | SBT40xSLN5/16"-2.5" | 5.075 | 2.5 | 0.6 | - | 1.378 | 1.043 | 0.3125 | 0.88 | 5/16"-24 | 1 | 1.12 |

| 5026-653-A24-250 | SBT40xSLN3/8"-2.5" | 5.075 | 2.5 | 0.75 | - | 1.535 | 1.24 | 0.375 | 1.25 | 3/8"-24 | 1 | 1.15 |

| 5026-653-A24-400 | SBT40xSLN3/8"-4" | 6.575 | 4 | 0.75 | - | 1.535 | 2.74 | 0.375 | 1 | 3/8"-24 | 1 | 1.07 |

| 5026-653-A28-250 | SBT40xSLN7/16"-2.5" | 5.075 | 2.5 | 0.812 | - | 1.535 | 1.24 | 0.4375 | 1.13 | 7/16"-20 | 1 | 1.1 |

| 5026-653-A32-250 | SBT40xSLN1/2"-2.5" | 5.075 | 2.5 | 0.875 | - | 1.732 | 1.319 | 0.5 | 1.25 | 7/16"-20 | 1 | 1.3 |

| 5026-653-A32-400 | SBT40xSLN1/2"-4" | 6.575 | 4 | 0.875 | - | 1.732 | 2.74 | 0.5 | 1.25 | 7/16"-20 | 1 | 1.18 |

| 5026-653-A40-250 | SBT40xSLN5/8"-2.5" | 5.075 | 2.5 | 0.937 | - | 1.85 | 1.319 | 0.625 | 1.5 | 1/2"-20 | 1 | 1.45 |

| 5026-653-A40-400 | SBT40xSLN5/8"-4" | 6.575 | 4 | 0.937 | - | 1.85 | 2.74 | 0.625 | 1.5 | 1/2"-20 | 1 | 1.23 |

| 5026-653-A48-250 | SBT40xSLN3/4"-2.5" | 5.075 | 2.5 | 1 | - | 1.929 | 1.319 | 0.75 | 1.75 | 5/8"-18 | 1 | 1.37 |

| 5026-653-A48-300 | SBT40xSLN3/4"-3" | 5.575 | 3 | 1 | - | 1.929 | 1.819 | 0.75 | 1.75 | 5/8"-18 | 1 | 1.65 |

| 5026-653-A48-400 | SBT40xSLN3/4"-4" | 6.575 | 4 | 1 | - | 1.929 | 2.819 | 0.75 | 1.75 | 5/8"-18 | 1 | 1.95 |

| 5026-653-A56-500 | SBT40xSLN7/8"-5" | 7.575 | 5 | 1.06 | 0.875 | 2.362 | 3.74 | 0.875 | 1.88 | 5/8"-18 | 1 | 1.59 |

| 5026-653-A64-356 | SBT40xSLN1"-3.563" | 6.137 | 3.563 | 1.046 | 1 | 2.559 | 2.421 | 1 | 2 | 3/4"-16 | 1 | 1.77 |

| 5026-653-A64-500 | SBT40xSLN1"-5" | 7.575 | 5 | 1.046 | 1 | 2.559 | 3.858 | 1 | 2 | 3/4"-16 | 1 | 1.93 |

| 5026-653-A72-356 | SBT40xSLN1-1/4"-3.563" | 6.137 | 3.563 | 1.125 | 1 | 2.559 | 2.539 | 1.25 | 2.5 | 3/4"-16 | 1 | 1.74 |

| 5026-653-A80-356 | SBT40xSLN1-1/2"-3.563" | 6.137 | 3.563 | 1.125 | 1 | 2.559 | 2.539 | 1.5 | 2.5 | 3/4"-16 | 1 | 3.62 |

| 5027-653-A16-300 | SBT50xSLN1/4"-3" | 7 | 3 | 0.63 | - | 1.378 | 1.11 | 0.25 | 0.78 | 1/4"-28 | 1 | 3.62 |

| 5027-653-A24-275 | SBT50xSLN3/8"-2.75" | 6.758 | 2.75 | 0.75 | - | 1.535 | 1.057 | 0.375 | 1 | 3/8"-24 | 1 | 3.61 |

| 5027-653-A32-300 | SBT50xSLN1/2"-3" | 7 | 3 | 0.875 | - | 1.732 | 1.386 | 0.5 | 1.25 | 7/16"-20 | 1 | 3.68 |

| 5027-653-A40-300 | SBT50xSLN5/8"-3" | 7 | 3 | 0.94 | - | 1.85 | 1.386 | 0.625 | 1.5 | 1/2"-20 | 1 | 3.77 |

| 5027-653-A48-300 | SBT50xSLN3/4"-3" | 7 | 3 | 1 | - | 1.929 | 1.386 | 0.75 | 1.75 | 5/8"-18 | 1 | 3.84 |

| 5027-653-A64-450 | SBT50xSLN1"-4.5" | 8.508 | 4.5 | 1.12 | 1 | 2.559 | 2.886 | 1 | 2 | 3/4"-16 | 1 | 4.27 |

| 5027-653-A64-600 | SBT50xSLN1"-6" | 10 | 6 | 1.125 | 1 | 2.559 | 4.11 | 1 | 2 | 3/4"-16 | 1 | 4.78 |

| 5027-653-A72-450 | SBT50xSLN1-1/4"-4.5" | 8.508 | 4.5 | 1.12 | 1 | 2.559 | 2.886 | 1.25 | 2.5 | 3/4"-16 | 1 | 4.65 |

| 5027-653-A80-400 | SBT50xSLN1-1/2"-4" | 8 | 4 | 1.12 | 1 | 2.559 | 2.504 | 1.5 | 2.5 | 3/4"-16 | 1 | 4.17 |

DualDRIVE+ SBT/SLN SIDE LOCK END MILL HOLDER (JIS TYPE)_figure.jpg)

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | l5 | d1 | d2 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 5026-654-006-075 | SBT40xSLN6-75JIS | 140.4 | 75 | 12 | 10 | 35 | 45 | 6 | 25 | M6 x 1.0P | 1.20 |

| 5026-654-008-075 | SBT40xSLN8-75JIS | 140.4 | 75 | 14 | 12 | 35 | 45 | 8 | 28 | M8 x 1.25P | 1.20 |

| 5026-654-010-075 | SBT40xSLN10-75JIS | 140.4 | 75 | 15 | 14 | 39 | 45 | 10 | 35 | M10 x 1.5P | 1.40 |

| 5026-654-012-075 | SBT40xSLN12-75JIS | 140.4 | 75 | 20 | 16 | 44 | 45 | 12 | 42 | M10 x 1.5P | 1.50 |

| 5026-654-016-075 | SBT40xSLN16-75JIS | 140.4 | 75 | 22 | 18 | 47 | 45 | 16 | 48 | M10 x 1.5P | 1.60 |

| 5026-654-020-090 | SBT40xSLN20-90JIS | 155.4 | 90 | 25 | 20 | 55 | 60 | 20 | 50 | M12 x 1.75P | 1.75 |

| 5026-654-025-090 | SBT40xSLN25-90JIS | 155.4 | 90 | 24 | 25 | 58 | 60 | 25 | 50 | M12 x 1.75P | 1.70 |

| 5026-654-032-100 | SBT40xSLN32-100JIS | 165.4 | 100 | 24 | 28 | 63 | 73 | 32 | 60 | M16 x 2.0P | 2.10 |

| 5027-654-006-075 | SBT50xSLN6-75JIS | 176.8 | 75 | 12 | 10 | 35 | 27 | 6 | 25 | M6 x 1.0P | 3.90 |

| 5027-654-008-075 | SBT50xSLN8-75JIS | 176.8 | 75 | 14 | 12 | 35 | 27 | 8 | 28 | M8 x 1.25P | 3.90 |

| 5027-654-010-075 | SBT50xSLN10-75JIS | 176.8 | 75 | 15 | 14 | 39 | 32 | 10 | 35 | M10 x 1.5P | 3.90 |

| 5027-654-012-090 | SBT50xSLN12-90JIS | 191.8 | 90 | 20 | 16 | 44 | 42 | 12 | 42 | M10 x 1.5P | 3.90 |

| 5027-654-016-090 | SBT50xSLN16-90JIS | 191.8 | 90 | 22 | 18 | 47 | 42 | 16 | 48 | M10 x 1.5P | 3.90 |

| 5027-654-020-090 | SBT50xSLN20-90JIS | 191.8 | 90 | 25 | 20 | 55 | 49 | 20 | 50 | M12 x 1.75P | 4.50 |

| 5027-654-025-100 | SBT50xSLN25-100JIS | 201.8 | 100 | 24 | 25 | 58 | 59 | 25 | 50 | M12 x 1.75P | 4.58 |

| 5027-654-032-105 | SBT50xSLN32-105JIS | 206.8 | 105 | 24 | 28 | 63 | 64 | 32 | 60 | M16 x 2.0P | 4.89 |

_figure2.jpg)

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | l5 | d1 | d2 | d3 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5026-654-006-150 | SBT40xSLN6-150JIS | 215.4 | 150 | 12 | 10 | 35 | 113 | 6 | 25 | 30 | M6 x 1.0P | 1.50 |

| 5026-654-008-150 | SBT40xSLN8-150JIS | 215.4 | 150 | 14 | 12 | 35 | 113 | 8 | 28 | 33 | M8 x 1.25P | 1.50 |

| 5026-654-010-150 | SBT40xSLN10-150JIS | 215.4 | 150 | 15 | 14 | 39 | 118 | 10 | 35 | 40 | M10 x 1.5P | 1.50 |

| 5026-654-012-150 | SBT40xSLN12-150JIS | 215.4 | 150 | 20 | 16 | 44 | 118 | 12 | 42 | 47 | M10 x 1.5P | 1.70 |

| 5026-654-016-150 | SBT40xSLN16-150JIS | 215.4 | 150 | 22 | 18 | 47 | 120 | 16 | 48 | 53 | M10 x 1.5P | 1.70 |

| 5026-654-020-150 | SBT40xSLN20-150JIS | 215.4 | 150 | 25 | 20 | 55 | 120 | 20 | 52 | 57 | M12 x 1.75P | 1.80 |

| 5027-654-012-165 | SBT50xSLN12-165JIS | 266.8 | 165 | 20 | 16 | 44 | 124 | 12 | 42 | 47 | M10 x 1.5P | 5.00 |

| 5027-654-016-165 | SBT50xSLN16-165JIS | 266.8 | 165 | 22 | 18 | 47 | 117 | 16 | 48 | 53 | M10 x 1.5P | 5.00 |

| 5027-654-020-165 | SBT50xSLN20-165JIS | 266.8 | 165 | 25 | 20 | 55 | 117 | 20 | 50 | 57 | M12 x 1.75P | 6.00 |

| 5027-654-020-210 | SBT50xSLN20-210JIS | 311.8 | 210 | 25 | 20 | 55 | 162 | 20 | 50 | 57 | M12 x 1.75P | 7.00 |

| 5027-654-025-165 | SBT50xSLN25-165JIS | 266.8 | 165 | 24 | 25 | 58 | 117 | 25 | 50 | 57 | M12 x 1.75P | 5.50 |

| 5027-654-025-210 | SBT50xSLN25-210JIS | 311.8 | 210 | 24 | 25 | 58 | 162 | 25 | 50 | 57 | M12 x 1.75P | 6.00 |

| 5027-654-025-250 | SBT50xSLN25-250JIS | 351.8 | 250 | 24 | 25 | 58 | 202 | 25 | 50 | 57 | M12 x 1.75P | 7.00 |

| 5027-654-032-165 | SBT50xSLN32-165JIS | 266.8 | 165 | 24 | 28 | 63 | 117 | 32 | 60 | 65 | M16 x 2.0P | 6.22 |

| 5027-654-032-210 | SBT50xSLN32-210JIS | 311.8 | 210 | 24 | 28 | 63 | 162 | 32 | 60 | 65 | M16 x 2.0P | 6.34 |

| 5027-654-032-250 | SBT50xSLN32-250JIS | 351.8 | 250 | 24 | 28 | 63 | 202 | 32 | 60 | 65 | M16 x 2.0P | 7.50 |

| 5027-654-032-300 | SBT50xSLN32-300JIS | 401.8 | 300 | 24 | 28 | 63 | 252 | 32 | 60 | 65 | M16 x 2.0P | 8.00 |

DualDRIVE+ SCAT/SLN SIDE LOCK END MILL HOLDER

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | l5 | d1 | d2 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 5043-653-A08-238 | SCAT40xSLN1/8"-2.375" | 5.062 | 2.375 | 0.37 | - | 0.787 | 0.8 | 0.125 | 0.69 | 6#-32 | 1.15 |

| 5043-653-A12-250 | SCAT40xSLN3/16"-2.5" | 5.187 | 2.5 | 0.562 | - | 0.984 | 0.73 | 0.1875 | 0.69 | 8#-32 | 1.20 |

| 5043-653-A16-300 | SCAT40xSLN1/4"-3" | 5.687 | 3 | 0.63 | - | 1.38 | 1.28 | 0.25 | 0.78 | 1/4-28 | 1.15 |

| 5043-653-A20-300 | SCAT40xSLN5/16"-3" | 5.687 | 3 | 0.63 | - | 1.38 | 1.11 | 0.3125 | 0.88 | 5/16-24 | 1.20 |

| 5043-653-A24-300 | SCAT40xSLN3/8"-3" | 5.687 | 3 | 0.75 | - | 1.535 | 1.08 | 0.375 | 1 | 3/8-24 | 1.20 |

| 5043-653-A32-300 | SCAT40xSLN1/2"-3" | 5.687 | 3 | 0.875 | - | 1.732 | 1.29 | 0.5 | 1.25 | 7/16-20 | 1.40 |

| 5043-653-A40-300 | SCAT40xSLN5/8"-3" | 5.687 | 3 | 0.937 | - | 1.85 | 1.46 | 0.625 | 1.5 | 1/2-20 | 1.50 |

| 5043-653-A48-300 | SCAT40xSLN3/4"-3" | 5.687 | 3 | 1 | - | 1.929 | 2.12 | 0.75 | 1.75 | 5/8-18 | 1.65 |

| 5043-653-A48-350 | SCAT40xSLN3/4"-3.5" | 6.187 | 3.5 | 1 | - | 1.929 | 2.12 | 0.75 | 1.75 | 5/8-18 | 1.70 |

| 5043-653-A56-350 | SCAT40xSLN7/8"-3.5" | 6.187 | 3.5 | 1.063 | 0.875 | 2.36 | 2.06 | 0.875 | 1.88 | 5/8-18 | 2.55 |

| 5043-653-A64-400 | SCAT40xSLN1"-4" | 6.687 | 4 | 1.125 | 1 | 2.56 | 2.5 | 1 | 2 | 3/4-16 | 2.80 |

| 5043-653-A72-460 | SCAT40xSLN1-1/4"-4.6" | 7.287 | 4.6 | 1.125 | 1 | 2.56 | 3.12 | 1.25 | 2.5 | 3/4-16 | 2.90 |

| 5043-653-A80-450 | SCAT40xSLN1-1/2"-4.5" | 7.187 | 4.5 | 1.125 | 1 | 2.56 | 3.02 | 1.5 | 2.5 | 3/4-16 | 3.20 |

| 5044-653-A16-400 | SCAT50xSLN1/4"-4" | 8 | 4 | 0.63 | - | 1.38 | 1.85 | 0.25 | 0.78 | 1/4-28 | 3.95 |

| 5044-653-A20-400 | SCAT50xSLN5/16"-4" | 8 | 4 | 0.63 | - | 1.38 | 2.23 | 0.3125 | 0.88 | 5/16-24 | 3.95 |

| 5044-653-A24-400 | SCAT50xSLN3/8"-4" | 8 | 4 | 0.781 | - | 1.535 | 1.89 | 0.375 | 1 | 3/8-24 | 4.00 |

| 5044-653-A32-400 | SCAT50xSLN1/2"-4" | 8 | 4 | 0.875 | - | 1.732 | 2.08 | 0.5 | 1.25 | 7/16-20 | 4.15 |

| 5044-653-A40-400 | SCAT50xSLN5/8"-4" | 8 | 4 | 0.937 | - | 1.85 | 1.83 | 0.625 | 1.5 | 1/2-20 | 4.30 |

| 5044-653-A48-400 | SCAT50xSLN3/4"-4" | 8 | 4 | 1 | - | 1.929 | 1.96 | 0.75 | 1.75 | 5/8-18 | 4.35 |

| 5044-653-A56-400 | SCAT50xSLN7/8"-4" | 8 | 4 | 1.063 | 0.875 | 2.36 | 2.43 | 0.875 | 1.88 | 5/8-18 | 5.30 |

| 5044-653-A64-400 | SCAT50xSLN1"-4" | 8 | 4 | 1.125 | 1 | 2.56 | 2.5 | 1 | 2 | 3/4-16 | 5.50 |

| 5044-653-A72-400 | SCAT50xSLN1-1/4"-4" | 8 | 4 | 1.125 | 1 | 2.756 | 2.5 | 1.25 | 2.5 | 3/4-16 | 5.65 |

| 5044-653-A72-460 | SCAT50xSLN1-1/4"-4.6" | 8.6 | 4.6 | 1.125 | 1 | 2.756 | 3.1 | 1.25 | 2.5 | 3/4-16 | 5.70 |

| 5044-653-A80-460 | SCAT50xSLN1-1/2"-4.6" | 8.6 | 4.6 | 1.125 | 1 | 2.756 | 3.14 | 1.5 | 2.5 | 3/4-16 | 5.70 |

| 5044-653-A96-600 | SCAT50xSLN2"-6" | 10 | 6 | 1.335 | 1.41 | 3.347 | 4.48 | 2 | 3.75 | 1-14 | 5.90 |

DualDRIVE+ SDAT/SLN SIDE LOCK END MILL HOLDER

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | d1 | d2 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|

| 5066-653-006-050 | SDAT40xSLN6-50 | 118.4 | 50 | 18 | - | 27 | 6 | 25 | M6 x 1.0P | 0.85 |

| 5066-653-008-050 | SDAT40xSLN8-50 | 118.4 | 50 | 18 | - | 27 | 8 | 28 | M8 x 1.25P | 1.00 |

| 5066-653-010-050 | SDAT40xSLN10-50 | 118.4 | 50 | 20 | - | 27 | 10 | 35 | M10 x 1.5P | 1.10 |

| 5066-653-012-050 | SDAT40xSLN12-50 | 118.4 | 50 | 22.5 | - | 30 | 12 | 42 | M12 x 1.75P | 1.15 |

| 5066-653-014-063 | SDAT40xSLN14-63 | 131.4 | 63 | 22.5 | - | 40.9 | 14 | 44 | M12 x 1.75P | 1.2 |

| 5066-653-016-063 | SDAT40xSLN16-63 | 131.4 | 63 | 24 | - | 43 | 16 | 48 | M14 x 2.0P | 1.40 |

| 5066-653-018-063 | SDAT40xSLN18-63 | 131.4 | 63 | 24 | - | 43.1 | 18 | 50 | M14 x 2.0P | 1.28 |

| 5066-653-020-063 | SDAT40xSLN20-63 | 131.4 | 63 | 25 | - | 43 | 20 | 52 | M16 x 2.0P | 1.30 |

| 5066-653-025-100 | SDAT40xSLN25-100 | 168.4 | 100 | 24 | 25 | 80 | 25 | 65 | M18 x 2.0P | 2.40 |

| 5066-653-032-100 | SDAT40xSLN32-100 | 168.4 | 100 | 24 | 28 | 80 | 32 | 72 | M20 x 2.0P | 2.70 |

| 5067-653-006-063 | SDAT50xSLN6-63 | 164.75 | 63 | 18 | - | 33 | 6 | 25 | M6 x 1.0P | 3.10 |

| 5067-653-008-063 | SDAT50xSLN8-63 | 164.75 | 63 | 18 | - | 33 | 8 | 28 | M8 x 1.25P | 3.10 |

| 5067-653-010-063 | SDAT50xSLN10-63 | 164.75 | 63 | 20 | - | 33 | 10 | 35 | M10 x 1.5P | 3.30 |

| 5067-653-012-063 | SDAT50xSLN12-63 | 164.75 | 63 | 22.5 | - | 40 | 12 | 42 | M12 x 1.75P | 3.50 |

| 5067-653-014-063 | SDAT50xSLN14-63 | 164.75 | 63 | 22.5 | - | 40.9 | 14 | 44 | M12 x 1.75P | 2.92 |

| 5067-653-016-063 | SDAT50xSLN16-63 | 164.75 | 63 | 24 | - | 40 | 16 | 48 | M14 x 2.0P | 3.45 |

| 5067-653-018-063 | SDAT50xSLN18-63 | 164.75 | 63 | 24 | - | 38.9 | 18 | 50 | M14 x 2.0P | 3.03 |

| 5067-653-020-063 | SDAT50xSLN20-63 | 164.75 | 63 | 25 | - | 40 | 20 | 52 | M16 x 2.0P | 3.50 |

| 5067-653-025-080 | SDAT50xSLN25-80 | 181.75 | 80 | 24 | 25 | 59 | 25 | 65 | M18 x 2.0P | 4.20 |

| 5067-653-032-100 | SDAT50xSLN32-100 | 201.75 | 100 | 24 | 28 | 78 | 32 | 72 | M20 x 2.0P | 5.00 |

| 5067-653-040-100 | SDAT50xSLN40-100 | 201.75 | 100 | 30 | 32 | 80 | 40 | 90 | M20 x 2.0P | 5.60 |

| 5067-653-042-100 | SDAT50xSLN42-100 | 201.75 | 100 | 30 | 32 | 80 | 42 | 90 | M20 x 2.0P | 5.70 |

| 5067-653-050-125 | SDAT50xSLN50-125 | 226.75 | 125 | 35 | 35 | 105 | 50 | 100 | M24 x 2.0P | 5.90 |

| 5067-653-063-150 | SDAT50xSLN63-150 | 251.75 | 150 | 40 | 40 | 130 | 63 | 125 | M20 x 2.0P | 6.20 |

HSK/SLN SIDE LOCK END MILL HOLDER

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | d1 | d2 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|

| 5072-653-006-065 | HSK50AxSLN6-65 | 90 | 65 | 34 | 18 | - | 6 | 25 | M6x1.0P | 0.70 |

| 5072-653-008-065 | HSK50AxSLN8-65 | 90 | 65 | 36 | 18 | - | 8 | 28 | M8x1.25P | 0.80 |

| 5072-653-010-065 | HSK50AxSLN10-65 | 90 | 65 | 36.5 | 20 | - | 10 | 35 | M10x1.5P | 0.80 |

| 5072-653-012-080 | HSK50AxSLN12-80 | 105 | 80 | 53.5 | 22.5 | - | 12 | 42 | M12x1.75P | 1.20 |

| 5072-653-014-080 | HSK50AxSLN14-80 | 105 | 80 | 53.5 | 22.5 | - | 14 | 44 | M12x1.75P | 1.30 |

| 5072-653-016-080 | HSK50AxSLN16-80 | 105 | 80 | 53.5 | 24 | - | 16 | 48 | M14x2.0P | 1.30 |

| 5072-653-018-080 | HSK50AxSLN18-80 | 105 | 80 | 53.5 | 24 | - | 18 | 50 | M14x2.0P | 1.40 |

| 5072-653-020-080 | HSK50AxSLN20-80 | 105 | 80 | 53 | 25 | - | 20 | 52 | M16x2.0P | 1.50 |

| 5073-653-006-065 | HSK63AxSLN6-65 | 97 | 65 | 36 | 18 | - | 6 | 25 | M6x1.0P | 0.90 |

| 5073-653-008-065 | HSK63AxSLN8-65 | 97 | 65 | 36 | 18 | - | 8 | 28 | M8x1.25P | 1.00 |

| 5073-653-010-065 | HSK63AxSLN10-65 | 97 | 65 | 36 | 20 | - | 10 | 35 | M10x1.5P | 1.00 |

| 5073-653-012-080 | HSK63AxSLN12-80 | 112 | 80 | 49 | 22.5 | - | 12 | 42 | M12x1.75P | 1.70 |

| 5073-653-014-080 | HSK63AxSLN14-80 | 112 | 80 | 51 | 22.5 | - | 14 | 44 | M12x1.75P | 1.70 |

| 5073-653-016-080 | HSK63AxSLN16-80 | 112 | 80 | 51.5 | 24 | - | 16 | 48 | M14x2.0P | 1.70 |

| 5073-653-018-080 | HSK63AxSLN18-80 | 112 | 80 | 52.5 | 24 | - | 18 | 50 | M14x2.0P | 1.80 |

| 5073-653-020-080 | HSK63AxSLN20-80 | 112 | 80 | 53.5 | 25 | - | 20 | 52 | M16x2.0P | 1.80 |

| 5073-653-025-110 | HSK63AxSLN25-110 | 142 | 110 | 83.2 | 24 | 25 | 25 | 65 | M18x2.0P | 2.50 |

| 5073-653-032-110 | HSK63AxSLN32-110 | 142 | 110 | 83.2 | 24 | 28 | 32 | 72 | M20x2.0P | 2.70 |

| 5075-653-006-080 | HSK100AxSLN6-80 | 130 | 80 | 41 | 18 | - | 6 | 25 | M6x1.0P | 3.00 |

| 5075-653-008-080 | HSK100AxSLN8-80 | 130 | 80 | 41 | 18 | - | 8 | 28 | M8x1.25P | 3.20 |

| 5075-653-010-080 | HSK100AxSLN10-80 | 130 | 80 | 46 | 20 | - | 10 | 35 | M10x1.5P | 3.40 |

| 5075-653-012-080 | HSK100AxSLN12-80 | 130 | 80 | 46 | 22.5 | - | 12 | 42 | M12x1.75P | 3.40 |

| 5075-653-014-080 | HSK100AxSLN14-80 | 130 | 80 | 46 | 22.5 | - | 14 | 44 | M12x1.75P | 3.50 |

| 5075-653-016-100 | HSK100AxSLN16-100 | 150 | 100 | 66 | 24 | - | 16 | 48 | M14x2.0P | 3.80 |

| 5075-653-018-100 | HSK100AxSLN18-100 | 150 | 100 | 66 | 24 | - | 18 | 50 | M16x2.0P | 3.80 |

| 5075-653-020-100 | HSK100AxSLN20-100 | 150 | 100 | 61 | 25 | - | 20 | 52 | M16x2.0P | 3.90 |

| 5075-653-025-100 | HSK100AxSLN25-100 | 150 | 100 | 66 | 24 | 25 | 25 | 65 | M18x2.0P | 4.00 |

| 5075-653-032-100 | HSK100AxSLN32-100 | 150 | 100 | 66 | 24 | 28 | 32 | 72 | M20x2.0P | 4.10 |

| 5075-653-040-120 | HSK100AxSLN40-120 | 170 | 120 | 89 | 30 | 32 | 40 | 90 | M20x2.0P | 4.40 |

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | d1 | d2 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|

| 5076-653-010-085 | HSK125AxSLN10-85 | 148 | 85 | 41.5 | 20 | - | 10 | 35 | M10x1.5P | 4.20 |

| 5076-653-012-090 | HSK125AxSLN12-90 | 153 | 90 | 51 | 22.5 | - | 12 | 42 | M12x1.75P | 4.30 |

| 5076-653-014-090 | HSK125AxSLN14-90 | 153 | 90 | 51 | 22.5 | - | 14 | 44 | M12x1.75P | 4.30 |

| 5076-653-016-095 | HSK125AxSLN16-95 | 158 | 95 | 56 | 24 | - | 16 | 48 | M14x2.0P | 4.50 |

| 5076-653-020-095 | HSK125AxSLN20-95 | 158 | 95 | 56 | 25 | - | 20 | 52 | M16x2.0P | 4.60 |

| 5076-653-025-100 | HSK125AxSLN25-100 | 163 | 100 | 66 | 24 | 25 | 25 | 65 | M18x2.0P | 4.90 |

| 5076-653-032-105 | HSK125AxSLN32-105 | 168 | 105 | 71 | 24 | 28 | 32 | 72 | M20x2.0P | 5.30 |

| 5076-653-040-120 | HSK125AxSLN40-120 | 183 | 120 | 86 | 30 | 32 | 40 | 90 | M20x2.0P | 6.85 |

| 5076-653-050-130 | HSK125AxSLN50-130 | 193 | 130 | 96 | 35 | 35 | 50 | 98 | M24x2.0P | 7.55 |

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | d1 | d2 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|

| 5071-653-A16-250 | HSK40AxSLN1/4"-2.5" | 3.287 | 2.5 | 1.516 | 0.63 | - | 0.25 | 0.78 | 1/4 - 28 | 0.31 |

| 5071-653-A24-250 | HSK40AxSLN3/8"-2.5" | 3.287 | 2.5 | 1.594 | 0.75 | - | 0.375 | 1 | 3/8 - 24 | 0.42 |

| 5071-653-A32-275 | HSK40AxSLN1/2"-2.75" | 3.537 | 2.75 | 1.923 | 0.875 | - | 0.5 | 1.38 | 7/16 - 20 | 0.57 |

| 5071-653-A40-300 | HSK40AxSLN5/8"-3" | 3.787 | 3 | 2.181 | 0.937 | - | 0.625 | 1.63 | 1/2 - 20 | 0.69 |

| 5073-653-A16-300 | HSK63AxSLN1/4"-3" | 4.26 | 3 | 1.78 | 0.63 | - | 0.25 | 0.78 | 1/4 - 28 | 0.76 |

| 5073-653-A24-300 | HSK63AxSLN3/8"-3" | 4.26 | 3 | 1.78 | 0.75 | - | 0.375 | 1 | 3/8 - 24 | 0.88 |

| 5073-653-A32-300 | HSK63AxSLN1/2"-3" | 4.26 | 3 | 1.78 | 0.875 | - | 0.5 | 1.38 | 7/16 - 20 | 1.13 |

| 5073-653-A40-375 | HSK63AxSLN5/8"-3.75" | 5 | 3.75 | 2.53 | 0.937 | - | 0.625 | 1.63 | 1/2 - 20 | 1.26 |

| 5073-653-A48-375 | HSK63AxSLN3/4"-3.75" | 5 | 3.75 | 2.648 | 1 | - | 0.75 | 1.75 | 5/8 - 18 | 1.33 |

| 5073-653-A64-375 | HSK63AxSLN1"-3.75" | 5 | 3.75 | 2.687 | 1.125 | 1 | 1 | 2 | 3/4 - 16 | 2.30 |

| 5073-653-A72-425 | HSK63AxSLN1-1/4"-4.25" | 5.51 | 4.25 | 3.187 | 1.125 | 1 | 1.25 | 2.5 | 3/4 - 16 | 2.52 |

| 5075-653-A16-300 | HSK100AxSLN1/4"-3" | 4.97 | 3 | 1.465 | 0.63 | - | 0.25 | 0.78 | 1/4 - 28 | 2.16 |

| 5075-653-A24-300 | HSK100AxSLN3/8"-3" | 4.97 | 3 | 1.661 | 0.75 | - | 0.375 | 1 | 3/8 - 24 | 2.31 |

| 5075-653-A32-325 | HSK100AxSLN1/2"-3.25" | 5.219 | 3.25 | 1.911 | 0.875 | - | 0.5 | 1.38 | 7/16 - 20 | 2.45 |

| 5075-653-A40-375 | HSK100AxSLN5/8"-3.75" | 5.719 | 3.75 | 2.411 | 0.937 | - | 0.625 | 1.63 | 1/2 - 20 | 2.84 |

| 5075-653-A48-375 | HSK100AxSLN3/4"-3.75" | 5.719 | 3.75 | 2.411 | 1 | - | 0.75 | 1.75 | 5/8 - 18 | 2.95 |

| 5075-653-A64-425 | HSK100AxSLN1"-4.25" | 6.219 | 4.25 | 2.911 | 1.125 | 1 | 1 | 2 | 3/4 - 16 | 3.46 |

| 5075-653-A72-425 | HSK100AxSLN1-1/4"-4.25" | 6.219 | 4.25 | 2.911 | 1.125 | 1 | 1.25 | 2.5 | 3/4 - 16 | 3.73 |

| 5075-653-A80-450 | HSK100AxSLN1-1/2"-4.5" | 6.469 | 4.5 | 3.161 | 1.125 | 1 | 1.5 | 2.5 | 3/4 - 16 | 5.51 |

| 5075-653-A96-550 | HSK100AxSLN2"-5.5" | 7.469 | 5.5 | 4.319 | 1.41 | 1.5 | 2 | 3.75 | 1 - 14 | 6.37 |

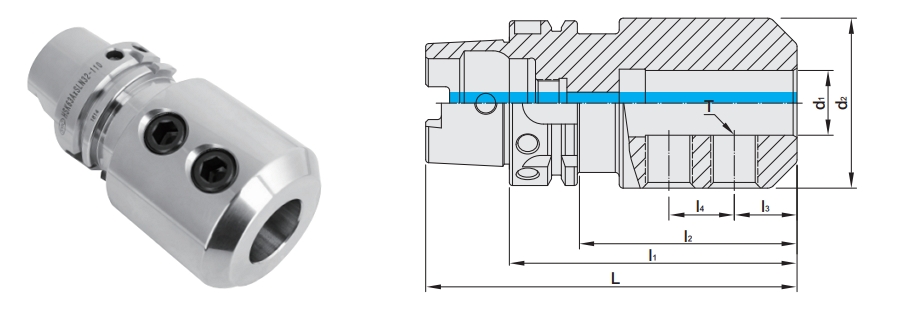

HSK/SLN SIDE LOCK END MILL HOLDER (JIS TYPE)

_figure.jpg)

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | l5 | d1 | d2 | d3 | T | Fig. | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5073-654-010-075 | HSK63AxSLN10-75JIS | 107 | 75 | 15 | 14 | 39 | 46 | 10 | 35 | - | M10x1.5P | 1 | 0.94 |

| 5073-654-010-150 | HSK63AxSLN10-150JIS | 182 | 150 | 15 | 14 | 39 | 119 | 10 | 35 | 40 | M10x1.5P | 2 | 1.56 |

| 5073-654-012-080 | HSK63AxSLN12-80JIS | 112 | 80 | 20 | 16 | 44 | 51 | 12 | 42 | - | M10x1.5P | 1 | 1.12 |

| 5073-654-012-150 | HSK63AxSLN12-150JIS | 182 | 150 | 20 | 16 | 44 | 121 | 12 | 42 | 47 | M10x1.5P | 2 | 1.94 |

| 5073-654-016-090 | HSK63AxSLN16-90JIS | 122 | 90 | 22 | 18 | 47 | 62 | 16 | 48 | - | M10x1.5P | 1 | 1.38 |

| 5073-654-016-150 | HSK63AxSLN16-150JIS | 182 | 150 | 22 | 18 | 47 | 123 | 16 | 48 | 53 | M10x1.5P | 2 | 2.31 |

| 5073-654-020-090 | HSK63AxSLN20-90JIS | 122 | 90 | 25 | 20 | 55 | 62.5 | 20 | 50 | - | M12x1.75P | 1 | 1.41 |

| 5073-654-020-150 | HSK63AxSLN20-150JIS | 182 | 150 | 25 | 20 | 55 | 123 | 20 | 50 | 53 | M12x1.75P | 2 | 2.35 |

| 5073-654-025-090 | HSK63AxSLN25-90JIS | 122 | 90 | 24 | 25 | 58 | 62.5 | 25 | 50 | - | M12x1.75P | 1 | 1.31 |

| 5073-654-025-150 | HSK63AxSLN25-150JIS | 182 | 150 | 24 | 25 | 58 | 123 | 25 | 50 | 53 | M12x1.75P | 2 | 2.25 |

| 5073-654-032-105 | HSK63AxSLN32-105JIS | 137 | 105 | 24 | 28 | 63 | 79 | 32 | 60 | - | M16x2.0P | 1 | 1.73 |

| 5074-654-032-105 | HSK80AxSLN32-105JIS | 145 | 105 | 24 | 28 | 63 | 76 | 32 | 60 | - | M16x2.0P | 1 | 2.22 |

HSK/SLN SIDE LOCK END MILL HOLDER (FID TYPE)

_figure.jpg)

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | d1 | d2 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|

| 5072-S35-006-065 | HSK50AxSLN6-65-FID | 90 | 65 | 34 | 18 | - | 6 | 25 | M6x1.0P | 0.70 |

| 5072-S35-008-065 | HSK50AxSLN8-65-FID | 90 | 65 | 36 | 18 | - | 8 | 28 | M8x1.25P | 0.80 |

| 5072-S35-010-065 | HSK50AxSLN10-65-FID | 90 | 65 | 36.5 | 20 | - | 10 | 35 | M10x1.5P | 0.80 |

| 5072-S35-012-080 | HSK50AxSLN12-80-FID | 105 | 80 | 53.5 | 22.5 | - | 12 | 42 | M12x1.75P | 1.20 |

| 5072-S35-014-080 | HSK50AxSLN14-80-FID | 105 | 80 | 53.5 | 22.5 | - | 14 | 44 | M12x1.75P | 1.30 |

| 5072-S35-016-080 | HSK50AxSLN16-80-FID | 105 | 80 | 53.5 | 24 | - | 16 | 48 | M14x2.0P | 1.30 |

| 5072-S35-018-080 | HSK50AxSLN18-80-FID | 105 | 80 | 53.5 | 24 | - | 18 | 50 | M14x2.0P | 1.40 |

| 5072-S35-020-080 | HSK50AxSLN20-80-FID | 105 | 80 | 53 | 25 | - | 20 | 52 | M16x2.0P | 1.50 |

| 5073-S35-006-065 | HSK63AxSLN6-65-FID | 97 | 65 | 36 | 18 | - | 6 | 25 | M6x1.0P | 0.90 |

| 5073-S35-008-065 | HSK63AxSLN8-65-FID | 97 | 65 | 36 | 18 | - | 8 | 28 | M8x1.25P | 1.00 |

| 5073-S35-010-065 | HSK63AxSLN10-65-FID | 97 | 65 | 36 | 20 | - | 10 | 35 | M10x1.5P | 1.00 |

| 5073-S35-012-080 | HSK63AxSLN12-80-FID | 112 | 80 | 49 | 22.5 | - | 12 | 42 | M12x1.75P | 1.70 |

| 5073-S35-014-080 | HSK63AxSLN14-80-FID | 112 | 80 | 51 | 22.5 | - | 14 | 44 | M12x1.75P | 1.70 |

| 5073-S35-016-080 | HSK63AxSLN16-80-FID | 112 | 80 | 51.5 | 24 | - | 16 | 48 | M14x2.0P | 1.70 |

| 5073-S35-018-080 | HSK63AxSLN18-80-FID | 112 | 80 | 52.5 | 24 | - | 18 | 50 | M14x2.0P | 1.80 |

| 5073-S35-020-080 | HSK63AxSLN20-80-FID | 112 | 80 | 53.5 | 25 | - | 20 | 52 | M16x2.0P | 1.80 |

| 5073-S35-025-110 | HSK63AxSLN25-110-FID | 142 | 110 | 83.2 | 24 | 25 | 25 | 65 | M18x2.0P | 2.50 |

| 5073-S35-032-110 | HSK63AxSLN32-110-FID | 142 | 110 | 83.2 | 24 | 28 | 32 | 72 | M20x2.0P | 2.70 |

| 5075-S35-006-080 | HSK100AxSLN6-80-FID | 130 | 80 | 41 | 18 | - | 6 | 25 | M6x1.0P | 3.00 |

| 5075-S35-008-080 | HSK100AxSLN8-80-FID | 130 | 80 | 41 | 18 | - | 8 | 28 | M8x1.25P | 3.20 |

| 5075-S35-010-080 | HSK100AxSLN10-80-FID | 130 | 80 | 46 | 20 | - | 10 | 35 | M10x1.5P | 3.40 |

| 5075-S35-012-080 | HSK100AxSLN12-80-FID | 130 | 80 | 46 | 22.5 | - | 12 | 42 | M12x1.75P | 3.40 |

| 5075-S35-014-080 | HSK100AxSLN14-80-FID | 130 | 80 | 46 | 22.5 | - | 14 | 44 | M12x1.75P | 3.50 |

| 5075-S35-016-100 | HSK100AxSLN16-100-FID | 150 | 100 | 66 | 24 | - | 16 | 48 | M14x2.0P | 3.80 |

| 5075-S35-018-100 | HSK100AxSLN18-100-FID | 150 | 100 | 66 | 24 | - | 18 | 50 | M16x2.0P | 3.80 |

| 5075-S35-020-100 | HSK100AxSLN20-100-FID | 150 | 100 | 61 | 25 | - | 20 | 52 | M16x2.0P | 3.90 |

| 5075-S35-025-100 | HSK100AxSLN25-100-FID | 150 | 100 | 66 | 24 | 25 | 25 | 65 | M18x2.0P | 4.00 |

| 5075-S35-032-100 | HSK100AxSLN32-100-FID | 150 | 100 | 66 | 24 | 28 | 32 | 72 | M20x2.0P | 4.10 |

| 5075-S35-040-120 | HSK100AxSLN40-120-FID | 170 | 120 | 89 | 30 | 32 | 40 | 90 | M20x2.0P | 4.40 |

| 5076-S35-010-085 | HSK125AxSLN10-85-FID | 148 | 85 | 35 | 20 | - | 10 | 35 | M10x1.5P | 4.20 |

| 5076-S35-012-090 | HSK125AxSLN12-90-FID | 153 | 90 | 40 | 22.5 | - | 12 | 42 | M12x1.75P | 4.30 |

| 5076-S35-014-090 | HSK125AxSLN14-90-FID | 153 | 90 | 40 | 22.5 | - | 14 | 44 | M12x1.75P | 4.30 |

| 5076-S35-016-095 | HSK125AxSLN16-95-FID | 158 | 95 | 45 | 24 | - | 16 | 48 | M14x2.0P | 4.50 |

| 5076-S35-020-095 | HSK125AxSLN20-95-FID | 158 | 95 | 45 | 25 | - | 20 | 52 | M16x2.0P | 4.60 |

| 5076-S35-025-100 | HSK125AxSLN25-100-FID | 163 | 100 | 60 | 24 | 25 | 25 | 65 | M18x2.0P | 4.90 |

| 5076-S35-032-105 | HSK125AxSLN32-105-FID | 168 | 105 | 65 | 24 | 28 | 32 | 72 | M20x2.0P | 5.30 |

| 5076-S35-040-120 | HSK125AxSLN40-120-FID | 183 | 120 | 80 | 30 | 32 | 40 | 90 | M20x2.0P | 6.85 |

| 5076-S35-050-130 | HSK125AxSLN50-130-FID | 193 | 130 | 90 | 35 | 35 | 50 | 98 | M24x2.0P | 7.55 |

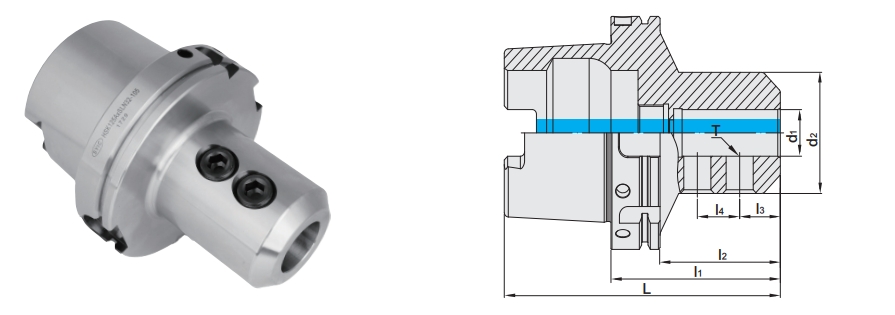

HSK/SLN SIDE LOCK END MILL HOLDER (JIS-FID TYPE)

_figure.jpg)

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | l5 | d1 | d2 | d3 | T | Fig. | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5073-S34-010-075 | HSK63AxSLN10-75JIS-FID | 107 | 75 | 15 | 14 | 39 | 46 | 10 | 35 | - | M10x1.5P | 1 | 0.94 |

| 5073-S34-010-150 | HSK63AxSLN10-150JIS-FID | 182 | 150 | 15 | 14 | 39 | 119 | 10 | 35 | 40 | M10x1.5P | 2 | 1.56 |

| 5073-S34-012-080 | HSK63AxSLN12-80JIS-FID | 112 | 80 | 20 | 16 | 44 | 51 | 12 | 42 | - | M10x1.5P | 1 | 1.12 |

| 5073-S34-012-150 | HSK63AxSLN12-150JIS-FID | 182 | 150 | 20 | 16 | 44 | 121 | 12 | 42 | 47 | M10x1.5P | 2 | 1.94 |

| 5073-S34-016-090 | HSK63AxSLN16-90JIS-FID | 122 | 90 | 22 | 18 | 47 | 62 | 16 | 48 | - | M10x1.5P | 1 | 1.38 |

| 5073-S34-016-150 | HSK63AxSLN16-150JIS-FID | 182 | 150 | 22 | 18 | 47 | 123 | 16 | 48 | 53 | M10x1.5P | 2 | 2.31 |

| 5073-S34-020-090 | HSK63AxSLN20-90JIS-FID | 122 | 90 | 25 | 20 | 55 | 62.5 | 20 | 50 | - | M12x1.75P | 1 | 1.41 |

| 5073-S34-020-150 | HSK63AxSLN20-150JIS-FID | 182 | 150 | 25 | 20 | 55 | 123 | 20 | 50 | 53 | M12x1.75P | 2 | 2.35 |

| 5073-S34-025-090 | HSK63AxSLN25-90JIS-FID | 122 | 90 | 24 | 25 | 58 | 62.5 | 25 | 50 | - | M12x1.75P | 1 | 1.31 |

| 5073-S34-025-150 | HSK63AxSLN25-150JIS-FID | 182 | 150 | 24 | 25 | 58 | 123 | 25 | 50 | 53 | M12x1.75P | 2 | 2.25 |

| 5073-S34-032-105 | HSK63AxSLN32-105JIS-FID | 137 | 105 | 24 | 28 | 63 | 79 | 32 | 60 | - | M16x2.0P | 1 | 1.73 |

HSK/SLNB SIDE LOCK END MILL HOLDER

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | d1 | d2 | t | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 5072-S50-006-080 | HSK50AxSLNB6-80 | 105 | 80 | 49 | 18 | - | 6 | 25 | M5 | M6x1.0P | 0.80 |

| 5072-S50-008-080 | HSK50AxSLNB8-80 | 105 | 80 | 49 | 18 | - | 8 | 28 | M6 | M8x1.25P | 0.90 |

| 5072-S50-010-080 | HSK50AxSLNB10-80 | 105 | 80 | 51 | 20 | - | 10 | 35 | M8 | M10x1.5P | 0.90 |

| 5072-S50-012-090 | HSK50AxSLNB12-90 | 115 | 90 | 64 | 22.5 | - | 12 | 42 | M10 | M12x1.75P | 1.30 |

| 5072-S50-014-090 | HSK50AxSLNB14-90 | 115 | 90 | 63.2 | 22.5 | - | 14 | 44 | M10 | M12x1.75P | 1.40 |

| 5072-S50-016-090 | HSK50AxSLNB16-90 | 115 | 90 | 63.2 | 24 | - | 16 | 48 | M12 | M14x2.0P | 1.40 |

| 5072-S50-018-090 | HSK50AxSLNB18-90 | 115 | 90 | 63.2 | 24 | - | 18 | 50 | M12 | M14x2.0P | 1.60 |

| 5072-S50-020-100 | HSK50AxSLNB20-100 | 125 | 100 | 73 | 25 | - | 20 | 52 | M16 | M16x2.0P | 1.70 |

| 5073-S50-006-080 | HSK63AxSLNB6-80 | 112 | 80 | 49 | 18 | - | 6 | 25 | M5 | M6x1.0P | 1.00 |

| 5073-S50-008-080 | HSK63AxSLNB8-80 | 112 | 80 | 49 | 18 | - | 8 | 28 | M6 | M8x1.25P | 1.10 |

| 5073-S50-010-080 | HSK63AxSLNB10-80 | 112 | 80 | 51 | 20 | - | 10 | 35 | M8 | M10x1.5P | 1.10 |

| 5073-S50-012-090 | HSK63AxSLNB12-90 | 122 | 90 | 64 | 22.5 | - | 12 | 42 | M10 | M12x1.75P | 2.00 |

| 5073-S50-014-090 | HSK63AxSLNB14-90 | 122 | 90 | 61 | 22.5 | - | 14 | 44 | M10 | M12x1.75P | 2.00 |

| 5073-S50-016-100 | HSK63AxSLNB16-100 | 132 | 100 | 72 | 24 | - | 16 | 48 | M12 | M14x2.0P | 2.00 |

| 5073-S50-018-100 | HSK63AxSLNB18-100 | 132 | 100 | 72.5 | 24 | - | 18 | 50 | M12 | M14x2.0P | 2.10 |

| 5073-S50-020-100 | HSK63AxSLNB20-100 | 132 | 100 | 72.5 | 25 | - | 20 | 52 | M16 | M16x2.0P | 2.10 |

| 5073-S50-025-110 | HSK63AxSLNB25-110 | 142 | 110 | 83.2 | 24 | 25 | 25 | 65 | M20 | M18x2.0P | 2.60 |

| 5073-S50-032-110 | HSK63AxSLNB32-110 | 142 | 110 | 82.5 | 24 | 24 | 32 | 72 | - | M20x2.0P | 2.80 |

| 5075-S50-006-090 | HSK100AxSLNB6-90 | 140 | 90 | 51 | 18 | - | 6 | 25 | M5 | M6x1.0P | 3.40 |

| 5075-S50-008-090 | HSK100AxSLNB8-90 | 140 | 90 | 51 | 18 | - | 8 | 28 | M6 | M8x1.25P | 3.50 |

| 5075-S50-010-090 | HSK100AxSLNB10-90 | 140 | 90 | 51 | 20 | - | 10 | 35 | M8 | M10x1.5P | 3.80 |

| 5075-S50-012-100 | HSK100AxSLNB12-100 | 150 | 100 | 61 | 22.5 | - | 12 | 42 | M10 | M12x1.75P | 3.80 |

| 5075-S50-014-100 | HSK100AxSLNB14-100 | 150 | 100 | 61 | 22.5 | - | 14 | 44 | M10 | M12x1.75P | 4.00 |

| 5075-S50-016-100 | HSK100AxSLNB16-100 | 150 | 100 | 66 | 24 | - | 16 | 48 | M12 | M14x2.0P | 4.00 |

| 5075-S50-018-100 | HSK100AxSLNB18-100 | 150 | 100 | 61 | 24 | - | 18 | 50 | M12 | M14x2.0P | 4.00 |

| 5075-S50-020-110 | HSK100AxSLNB20-110 | 160 | 110 | 71 | 25 | - | 20 | 52 | M16 | M16x2.0P | 4.20 |

| 5075-S50-025-120 | HSK100AxSLNB25-120 | 170 | 120 | 86 | 24 | 22 | 25 | 65 | M20 | M18x2.0P | 4.40 |

| 5075-S50-032-120 | HSK100AxSLNB32-120 | 170 | 120 | 86 | 24 | 24 | 32 | 72 | M20 | M20x2.0P | 4.50 |

| 5075-S50-040-120 | HSK100AxSLNB40-120 | 170 | 120 | 89 | 30 | 32 | 40 | 90 | M20 | M20x2.0P | 5.00 |

| 5076-S50-020-120 | HSK125AxSLNB20-120 | 183 | 120 | 80 | 25 | - | 20 | 52 | M16 | M16x2.0P | 4.80 |

| 5076-S50-025-130 | HSK125AxSLNB25-130 | 193 | 130 | 90 | 24 | 22 | 25 | 65 | M20 | M18x2.0P | 5.10 |

| 5076-S50-032-130 | HSK125AxSLNB32-130 | 193 | 130 | 90 | 24 | 24 | 32 | 72 | M20 | M20x2.0P | 5.50 |

| 5076-S50-040-140 | HSK125AxSLNB40-140 | 203 | 140 | 100 | 30 | 32 | 40 | 90 | M20 | M20x2.0P | 7.00 |

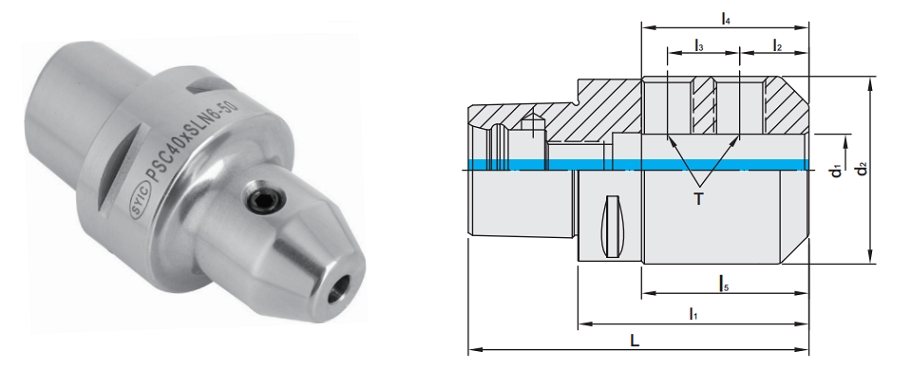

PSC/SLN SIDE LOCK END MILL HOLDER

| MODEL NO. | TYPE | L | l1 | l2 | l3 | l4 | l5 | d1 | d2 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 5140-653-006-045 | PSC32xSLN6-45 | 64 | 45 | 18 | - | 36 | 29 | 6 | 25 | M6 | 0.30 |

| 5140-653-008-045 | PSC32xSLN8-45 | 64 | 45 | 18 | - | 36 | 29.5 | 8 | 28 | M8 | 0.30 |

| 5140-653-010-050 | PSC32xSLN10-50 | 69 | 50 | 20 | - | 29 | 35 | 10 | 35 | M10 | 0.40 |

| 5140-653-012-055 | PSC32xSLN12-55 | 74 | 55 | 22.5 | - | 38 | 40 | 12 | 42 | M12 | 0.30 |

| 5141-653-006-050 | PSC40xSLN6-50 | 74 | 50 | 18 | - | 35 | 25 | 6 | 25 | M6 | 0.40 |

| 5141-653-008-050 | PSC40xSLN8-50 | 74 | 50 | 18 | - | 35 | 26 | 8 | 28 | M8 | 0.40 |

| 5141-653-010-050 | PSC40xSLN10-50 | 74 | 50 | 20 | - | 39 | 27.5 | 10 | 35 | M10 | 0.50 |

| 5141-653-012-055 | PSC40xSLN12-55 | 79 | 55 | 22.5 | - | 44 | 35 | 12 | 42 | M12 | 0.60 |

| 5141-653-014-055 | PSC40xSLN14-55 | 79 | 55 | 22.5 | - | 39 | 35 | 14 | 44 | M12 | 0.60 |

| 5141-653-016-055 | PSC40xSLN16-55 | 79 | 55 | 24 | - | 37 | 35 | 16 | 47 | M14 | 0.70 |

| 5142-653-006-050 | PSC50xSLN6-50 | 80 | 50 | 18 | - | 38 | 25 | 6 | 25 | M6 | 0.60 |

| 5142-653-008-050 | PSC50xSLN8-50 | 80 | 50 | 18 | - | 38 | 25 | 8 | 28 | M8 | 0.70 |

| 5142-653-010-055 | PSC50xSLN10-55 | 85 | 55 | 20 | - | 43 | 30 | 10 | 35 | M10 | 0.70 |

| 5142-653-012-060 | PSC50xSLN12-60 | 90 | 60 | 22.5 | - | 48 | 38 | 12 | 42 | M12 | 0.90 |

| 5142-653-014-060 | PSC50xSLN14-60 | 90 | 60 | 22.5 | - | 44 | 37 | 14 | 44 | M12 | 0.80 |

| 5142-653-016-060 | PSC50xSLN16-60 | 90 | 60 | 24 | - | 43 | 39 | 16 | 48 | M14 | 1.00 |

| 5142-653-018-060 | PSC50xSLN18-60 | 90 | 60 | 24 | - | 45 | - | 18 | 50 | M14 | 1.00 |

| 5142-653-020-060 | PSC50xSLN20-60 | 90 | 60 | 25 | - | 43 | 40 | 20 | 52 | M16 | 1.00 |

| 5142-653-025-080 | PSC50xSLN25-80 | 110 | 80 | 24 | 25 | 58 | 60 | 25 | 65 | M18 | 1.80 |

| 5143-653-006-055 | PSC63xSLN6-55 | 93 | 55 | 18 | - | 35 | 28 | 6 | 25 | M6 | 0.90 |

| 5143-653-008-055 | PSC63xSLN8-55 | 93 | 55 | 18 | - | 39 | 28 | 8 | 28 | M8 | 0.90 |

| 5143-653-010-060 | PSC63xSLN10-60 | 98 | 60 | 20 | - | 39 | 33 | 10 | 35 | M10 | 1.00 |

| 5143-653-012-060 | PSC63xSLN12-60 | 98 | 60 | 22.5 | - | 44 | 33 | 12 | 42 | M12 | 1.10 |

| 5143-653-014-060 | PSC63xSLN14-60 | 98 | 60 | 22.5 | - | 44 | 33 | 14 | 44 | M12 | 1.10 |

| 5143-653-016-065 | PSC63xSLN16-65 | 103 | 65 | 24 | - | 47 | 40 | 16 | 48 | M14 | 1.20 |

| 5143-653-018-065 | PSC63xSLN18-65 | 103 | 65 | 24 | - | 44 | 40 | 18 | 50 | M14 | 1.20 |

| 5143-653-020-065 | PSC63xSLN20-65 | 103 | 65 | 25 | 49 | 40 | 20 | 52 | M16 | 1.50 | |

| 5143-653-025-080 | PSC63xSLN25-80 | 118 | 80 | 24 | 25 | 58 | 58 | 25 | 65 | M18 | 1.90 |

| 5143-653-032-090 | PSC63xSLN32-90 | 128 | 90 | 24 | 28 | 63 | 68 | 32 | 72 | M20 | 2.40 |

| 5143-653-040-100 | PSC63xSLN40-100 | 138 | 100 | 30 | 32 | 75 | 78 | 40 | 90 | M20 | 3.70 |

| 5144-653-006-070 | PSC80xSLN6-70 | 118 | 70 | 18 | - | 35 | 35 | 6 | 25 | M6 | 2.10 |

| 5144-653-008-070 | PSC80xSLN8-70 | 118 | 70 | 18 | - | 35 | 35 | 8 | 28 | M8 | 2.10 |

| 5144-653-010-070 | PSC80xSLN10-70 | 118 | 70 | 20 | - | 39 | 35 | 10 | 35 | M10 | 2.20 |

| 5144-653-012-070 | PSC80xSLN12-70 | 118 | 70 | 22.5 | - | 44 | 35 | 12 | 42 | M12 | 2.20 |

| 5144-653-014-070 | PSC80xSLN14-70 | 118 | 70 | 22.5 | - | 44 | 35 | 14 | 44 | M12 | 2.30 |

| 5144-653-016-070 | PSC80xSLN16-70 | 118 | 70 | 24 | - | 47 | 35 | 16 | 48 | M14 | 2.30 |

| 5144-653-018-070 | PSC80xSLN18-70 | 118 | 70 | 24 | - | 44 | 35 | 18 | 50 | M14 | 2.30 |

| 5144-653-020-070 | PSC80xSLN20-70 | 118 | 70 | 25 | - | 49 | 37 | 20 | 52 | M16 | 2.30 |

| 5144-653-025-090 | PSC80xSLN25-90 | 138 | 90 | 24 | 25 | 58 | 59 | 25 | 65 | M18 | 2.40 |

| 5144-653-032-095 | PSC80xSLN32-95 | 143 | 95 | 24 | 28 | 63 | 63.5 | 32 | 72 | M20 | 2.90 |

| 5144-653-040-110 | PSC80xSLN40-110 | 158 | 110 | 30 | 32 | 75 | 79.5 | 40 | 90 | M20 | 4.50 |

| 5144-653-050-120 | PSC80xSLN50-120 | 168 | 120 | 35 | 35 | 78 | 90 | 50 | 98 | M24 | 5.50 |

| 5146-653-020-090 | PSC100xSLN20-90 | 150 | 90 | 25 | - | 49 | 44 | 20 | 52 | M16 | 3.91 |

| 5146-653-025-105 | PSC100xSLN25-105 | 165 | 105 | 24 | 25 | 58 | 64 | 25 | 65 | M18 | 4.56 |

| 5146-653-032-110 | PSC100xSLN32-110 | 170 | 110 | 24 | 28 | 63 | 69 | 32 | 72 | M20 | 4.93 |

| 5146-653-040-115 | PSC100xSLN40-115 | 175 | 115 | 30 | 32 | 75 | 78 | 40 | 90 | M20 | 6.10 |

| 5146-653-050-120 | PSC100xSLN50-120 | 180 | 120 | 35 | 35 | 78 | 84 | 50 | 98 | M24 | 6.40 |

| INCHES | |||||||||||

| 5140-653-A16-177 | PSC32xSLN1/4"-1.77" | 2.52 | 1.77 | 0.63 | - | 1.38 | 0.984 | 0.25 | 0.78 | 1/4 - 28 | 0.30 |

| 5140-653-A20-177 | PSC32xSLN5/16"-1.77" | 2.52 | 1.77 | 0.63 | - | 1.38 | 1.06 | 0.3125 | 0.88 | 5/16 - 24 | 0.30 |

| 5140-653-A24-197 | PSC32xSLN3/8"-1.97" | 2.72 | 1.97 | 0.75 | - | 1.38 | 1.34 | 0.375 | 1 | 3/8 - 24 | 0.40 |

| 5140-653-A32-217 | PSC32xSLN1/2"-2.17" | 2.91 | 2.17 | 0.875 | - | 1.732 | 1.57 | 0.5 | 1.25 | 7/16 - 20 | 0.30 |

| 5141-653-A16-197 | PSC40xSLN1/4"-1.97" | 2.91 | 1.97 | 0.63 | - | 1.38 | 0.984 | 0.25 | 0.78 | 1/4 - 28 | 0.40 |

| 5141-653-A20-197 | PSC40xSLN5/16"-1.97" | 2.91 | 1.97 | 0.6 | - | 1.38 | 1.06 | 0.3125 | 0.88 | 5/16 - 24 | 0.40 |

| 5141-653-A24-197 | PSC40xSLN3/8"-1.97" | 2.91 | 1.97 | 0.75 | - | 1.38 | 1.08 | 0.375 | 1 | 3/8 - 24 | 0.50 |

| 5141-653-A32-217 | PSC40xSLN1/2"-2.17" | 3.11 | 2.17 | 0.875 | - | 1.732 | 1.34 | 0.5 | 1.25 | 7/16 - 20 | 0.60 |

| 5141-653-A36-217 | PSC40xSLN9/16"-2.17" | 3.11 | 2.17 | 0.937 | - | 1.81 | 1.38 | 0.5625 | 1.75 | 1/2 - 20 | 0.60 |

| 5141-653-A40-217 | PSC40xSLN5/8"-2.17" | 3.11 | 2.17 | 0.937 | - | 1.73 | 1.34 | 0.625 | 1.5 | 1/2 - 20 | 0.70 |

| 5142-653-A16-200 | PSC50xSLN1/4"-2" | 3.18 | 2 | 0.63 | - | 1.38 | 1 | 0.25 | 0.78 | 1/4 - 28 | 0.60 |

| 5142-653-A20-200 | PSC50xSLN5/16"-2" | 3.18 | 2 | 0.6 | - | 1.38 | 1.02 | 0.3125 | 0.88 | 5/16 - 24 | 0.70 |

| 5142-653-A24-217 | PSC50xSLN3/8"-2.17" | 3.35 | 2.17 | 0.75 | - | 1.38 | 1.18 | 0.375 | 1 | 3/8 - 24 | 0.70 |

| 5142-653-A32-236 | PSC50xSLN1/2"-2.36" | 3.54 | 2.36 | 0.875 | - | 1.732 | 1.38 | 0.5 | 1.25 | 7/16 - 20 | 0.90 |

| 5142-653-A36-236 | PSC50xSLN9/16"-2.36" | 3.54 | 2.36 | 0.937 | - | 1.77 | 1.46 | 0.5625 | 1.75 | 1/2 - 20 | 0.80 |

| 5142-653-A40-236 | PSC50xSLN5/8"-2.36" | 3.54 | 2.36 | 0.937 | - | 1.69 | 1.46 | 0.625 | 1.5 | 1/2 - 20 | 1.00 |

| 5142-653-A48-236 | PSC50xSLN3/4"-2.36" | 3.54 | 2.36 | 1 | - | 1.69 | 1.53 | 0.75 | 1.75 | 5/8 - 18 | 1.00 |

| 5142-653-A64-315 | PSC50xSLN1"-3.15" | 4.33 | 3.15 | 1.125 | 1 | 2.559 | 2.36 | 1 | 2 | 3/4 - 16 | 1.00 |

| 5143-653-A16-217 | PSC63xSLN1/4"-2.17" | 3.66 | 2.17 | 0.63 | - | 1.38 | 1.102 | 0.25 | 0.78 | 1/4 - 28 | 1.80 |

| 5143-653-A20-217 | PSC63xSLN5/16"-2.17" | 3.66 | 2.17 | 0.6 | - | 1.38 | 1.102 | 0.3125 | 0.88 | 5/16 - 24 | 0.90 |

| 5143-653-A24-236 | PSC63xSLN3/8"-2.36" | 3.86 | 2.36 | 0.75 | - | 1.38 | 1.299 | 0.375 | 1 | 3/8 - 24 | 0.90 |

| 5143-653-A32-236 | PSC63xSLN1/2"-2.36" | 3.86 | 2.36 | 0.875 | - | 1.732 | 1.299 | 0.5 | 1.25 | 7/16 - 20 | 1.00 |

| 5143-653-A36-236 | PSC63xSLN9/16"-2.36" | 3.86 | 2.36 | 0.937 | - | 1.85 | 1.338 | 0.5625 | 1.75 | 1/2 - 20 | 1.10 |

| 5143-653-A40-256 | PSC63xSLN5/8"-2.56" | 4.06 | 2.56 | 0.937 | - | 1.85 | 1.496 | 0.625 | 1.5 | 1/2 - 20 | 1.10 |

| 5143-653-A48-256 | PSC63xSLN3/4"-2.56" | 4.06 | 2.56 | 1 | - | 1.929 | 1.496 | 0.75 | 1.75 | 5/8 - 18 | 1.20 |

| 5143-653-A64-315 | PSC63xSLN1"-3.15" | 4.65 | 3.15 | 1.125 | - | 2.559 | 2.283 | 1 | 2 | 3/4 - 16 | 1.20 |

| 5143-653-A72-354 | PSC63xSLN1-1/4"-3.54" | 5.04 | 3.54 | 1.125 | 1 | 2.559 | 2.677 | 1.25 | 2.5 | 3/4 - 16 | 1.50 |

| 5143-653-A80-394 | PSC63xSLN1-1/2"-3.94" | 5.43 | 3.94 | 1.125 | 1 | 2.56 | 3.07 | 1.5 | 2.5 | 3/4 - 16 | 1.90 |

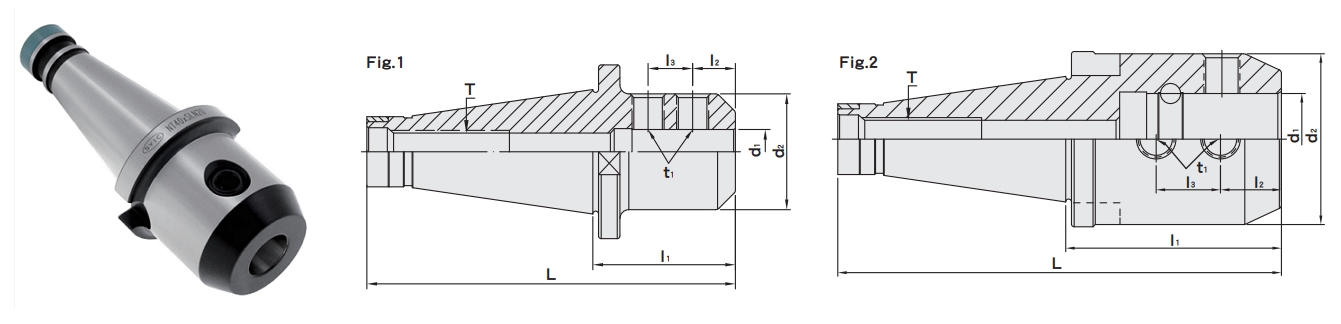

NT/SLN SIDE LOCK END MILL HOLDER

| MODEL NO. | TYPE | L | l1 | l2 | l3 | d1 | d2 | t1 | T DRAW BAR | Fig. | WEIGHT (KGS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5120-653-061/5-040 | NT30xSLN6-40 | 108.4 | 40 | 18 | - | 6 | 25 | M6 x 1.0P | 1/2"-12 | M12x1.75P | 1 | 0.50 |

| 5120-653-081/5-040 | NT30xSLN8-40 | 108.4 | 40 | 18 | - | 8 | 28 | M8 x 1.25P | 1/2"-12 | M12x1.75P | 1 | 0.60 |

| 5120-653-101/5-040 | NT30xSLN10-40 | 108.4 | 40 | 20 | - | 10 | 35 | M10 x 1.5P | 1/2"-12 | M12x1.75P | 1 | 0.60 |

| 5120-653-121/5-050 | NT30xSLN12-50 | 118.4 | 50 | 22.5 | - | 12 | 42 | M12x 1.75P | 1/2"-12 | M12x1.75P | 1 | 0.65 |

| 5120-653-161/5-050 | NT30xSLN16-50 | 118.4 | 50 | 24 | - | 16 | 48 | M14 x 2.0P | 1/2"-12 | M12x1.75P | 1 | 0.75 |

| 5120-653-201/5-063 | NT30xSLN20-63 | 131.4 | 63 | 25 | - | 20 | 52 | M16 x 2.0P | 1/2"-12 | M12x1.75P | 1 | 1.10 |

| 5120-653-251/5-080 | NT30xSLN25-80 | 148.4 | 80 | 24 | 25 | 25 | 63.5 | M18 x 2.0P | 1/2"-12 | M12x1.75P | 1 | 1.20 |

| 5121-653-061/5-050 | NT40xSLN6-50 | 143.4 | 50 | 18 | - | 6 | 25 | M6 x 1.0P | 5/8"-11 | M16x2.0P | 1 | 0.90 |

| 5121-653-081/5-050 | NT40xSLN8-50 | 143.4 | 50 | 18 | - | 8 | 28 | M8 x 1.25P | 5/8"-11 | M16x2.0P | 1 | 0.95 |

| 5121-653-101/5-050 | NT40xSLN10-50 | 143.4 | 50 | 20 | - | 10 | 35 | M10 x 1.5P | 5/8"-11 | M16x2.0P | 1 | 1.10 |

| 5121-653-121/5-050 | NT40xSLN12-50 | 143.4 | 50 | 22.5 | - | 12 | 42 | M12 x 1.75P | 5/8"-11 | M16x2.0P | 1 | 1.00 |

| 5121-653-161/5-063 | NT40xSLN16-63 | 156.4 | 63 | 24 | - | 16 | 48 | M14 x 2.0P | 5/8"-11 | M16x2.0P | 1 | 1.40 |

| 5121-653-201/5-063 | NT40xSLN20-63 | 156.4 | 63 | 25 | - | 20 | 52 | M16 x 2.0P | 5/8"-11 | M16x2.0P | 1 | 1.45 |

| 5121-653-251/5-080 | NT40xSLN25-80 | 173.4 | 80 | 24 | 25 | 25 | 65 | M18 x 2.0P | 5/8"-11 | M16x2.0P | 1 | 2.10 |

| 5121-653-321/5-080 | NT40xSLN32-80 | 173.4 | 80 | 24 | 28 | 32 | 72 | M20 x 2.0P | 5/8"-11 | M16x2.0P | 1 | 2.50 |

| 5122-653-061/5-063 | NT50xSLN6-63 | 189.8 | 63 | 18 | - | 6 | 25 | M6 x 1P | 1"-8 | M24x3.0P | 1 | 2.90 |

| 5122-653-081/5-063 | NT50xSLN8-63 | 189.8 | 63 | 18 | - | 8 | 28 | M8 x 1.25P | 1"-8 | M24x3.0P | 1 | 3.00 |

| 5122-653-101/5-063 | NT50xSLN10-63 | 189.8 | 63 | 20 | - | 10 | 35 | M10 x 1.5P | 1"-8 | M24x3.0P | 1 | 3.20 |

| 5122-653-121/5-063 | NT50xSLN12-63 | 189.8 | 63 | 22.5 | - | 12 | 42 | M12 x 1.75P | 1"-8 | M24x3.0P | 1 | 3.30 |

| 5122-653-161/5-063 | NT50xSLN16-63 | 189.8 | 63 | 24 | - | 16 | 48 | M14 x 2.0P | 1"-8 | M24x3.0P | 1 | 3.50 |

| 5122-653-201/5-063 | NT50xSLN20-63 | 189.8 | 63 | 25 | - | 20 | 52 | M16 x 2.0P | 1"-8 | M24x3.0P | 1 | 3.60 |

| 5122-653-251/5-080 | NT50xSLN25-80 | 206.8 | 80 | 24 | 25 | 25 | 65 | M18 x 2.0P | 1"-8 | M24x3.0P | 1 | 4.20 |

| 5122-653-321/5-080 | NT50xSLN32-80 | 206.8 | 80 | 24 | 28 | 32 | 72 | M20 x 2.0P | 1"-8 | M24x3.0P | 1 | 4.40 |

| 5122-653-401/5-100 | NT50xSLN40-100 | 226.8 | 100 | 30 | 32 | 40 | 90 | M20 x 2.0P | 1"-8 | M24x3.0P | 1 | 4.40 |

| 5122-653-401/5-120 | NT50xSLN40-120 | 246.8 | 120 | 30 | 32 | 40 | 90 | M20 x 2.0P | 1"-8 | M24x3.0P | 1 | 4.20 |

| 5122-653-421/5-100 | NT50xSLN42-100 | 226.8 | 100 | 30 | 32 | 42 | 90 | M20 x 2.0P | 1"-8 | M24x3.0P | 1 | 4.60 |

| 5122-653-501/5-120 | NT50xSLN50-120 | 246.8 | 120 | 35 | 35 | 50 | 95 | M24 x 2.0P | 1"-8 | M24x3.0P | 1 | 4.80 |

| 5122-653-631/5-120 | NT50xSLN63-120 | 246.8 | 120 | 40 | 40 | 63 | 125 | M20 x 2.0P | 1"-8 | M24x3.0P | 1 | 5.40 |

| 5122-653-A961/5-472 | NT50xSLN50.8-120 | 246.8 | 120 | 33.1 | 28.58 | 50.8 | 95 | M20 x 2.0P | 1"-8 | M24x3.0P | 1 | 5.00 |

| 5122-677-A961/5-472 | NT50xSLN50.8-120 | 246.8 | 120 | 33.1 | 28.58 | 50.8 | 95 | M20 x 2.0P | 1"-8 | M24x3.0P | 2 | 5.00 |

STRAIGHT SHANK SIDE LOCK HOLDER

| MODEL NO. | TYPE | L | l2 | l3 | l4 | D | d1 | d2 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|

| 5272-803-00804-110 | C8xSL4-110 | 110 | 6 | 10 | 25 | 8 | 4 | 8 | M3 x 0.5P | 0.10 |

| 5272-803-01003-150 | C10xSL3-150 | 150 | 6 | 10 | 20 | 10 | 3 | 9 | M3 x 0.5P | 0.10 |

| 5272-803-01004-150 | C10xSL4-150 | 150 | 6 | 10 | 25 | 10 | 4 | 9 | M4 x 0.7P | 0.10 |

| 5272-803-01006-150 | C10xSL6-150 | 150 | 6 | 10 | 25 | 10 | 6 | - | M4 x 0.7P | 0.10 |

| 5272-803-01204-150 | C12xSL4-150 | 150 | 6 | 10 | 25 | 12 | 4 | 9 | M4 x 0.7P | 0.12 |

| 5272-803-01206-100 | C12xSL6-100 | 100 | 6 | 10 | 25 | 12 | 6 | 10 | M4 x 0.7P | 0.10 |

| 5272-803-01206-150 | C12xSL6-150 | 150 | 6 | 10 | 25 | 12 | 6 | 10 | M4 x 0.7P | 0.12 |

| 5272-803-01604-150 | C16xSL4-150 | 150 | 6 | 10 | 25 | 16 | 4 | 10 | M4 x 0.7P | 0.15 |

| 5272-803-01604-200 | C16xSL4-200 | 200 | 6 | 10 | 25 | 16 | 4 | 10 | M4 x 0.7P | 0.18 |

| 5272-803-01606-150 | C16xSL6-150 | 150 | 6 | 10 | 25 | 16 | 6 | 13 | M4 x 0.7P | 0.15 |

| 5272-803-01606-200 | C16xSL6-200 | 200 | 6 | 10 | 25 | 16 | 6 | 13 | M4 x 0.7P | 0.18 |

| 5272-803-01608-150 | C16xSL8-150 | 150 | 6 | 10 | 25 | 16 | 8 | 15 | M4 x 0.7P | 0.15 |

| 5272-803-01608-200 | C16xSL8-200 | 200 | 6 | 10 | 25 | 16 | 8 | 15 | M4 x 0.7P | 0.18 |

| 5272-803-02006-150 | C20xSL6-150 | 150 | 6 | 10 | 25 | 20 | 6 | 13 | M4 x 0.7P | 0.18 |

| 5272-803-02008-150 | C20xSL8-150 | 150 | 6 | 10 | 25 | 20 | 8 | 15 | M6 x 1.0P | 0.18 |

| 5272-803-02008-200 | C20xSL8-200 | 200 | 6 | 10 | 25 | 20 | 8 | 15 | M6 x 1.0P | 0.18 |

| 5272-803-02010-150 | C20xSL10-150 | 150 | 6 | 10 | 25 | 20 | 10 | 17 | M6 x 1.0P | 0.18 |

| 5272-803-02010-200 | C20xSL10-200 | 200 | 6 | 10 | 25 | 20 | 10 | 17 | M6 x 1.0P | 0.20 |

| 5272-803-02012-150 | C20xSL12-150 | 150 | 6 | 10 | 25 | 20 | 12 | 19 | M6 x 1.0P | 0.18 |

| 5272-803-02012-200 | C20xSL12-200 | 200 | 6 | 10 | 25 | 20 | 12 | 19 | M6 x 1.0P | 0.20 |

| 5272-803-03206-150 | C32xSL6-150 | 150 | 6 | 10 | 25 | 32 | 6 | 13 | M6 x 1.0P | 0.21 |

| 5272-803-03208-150 | C32xSL8-150 | 150 | 6 | 10 | 25 | 32 | 8 | 15 | M6 x 1.0P | 0.21 |

| 5272-803-03210-150 | C32xSL10-150 | 150 | 6 | 10 | 25 | 32 | 10 | 17 | M6 x 1.0P | 0.22 |

| 5272-803-03212-150 | C32xSL12-150 | 150 | 6 | 10 | 25 | 32 | 12 | 19 | M6 x 1.0P | 0.22 |

Back

Back