- Home

- Products

- Tool Holder for Machining Center

- Slim-Fit Collet Chuck

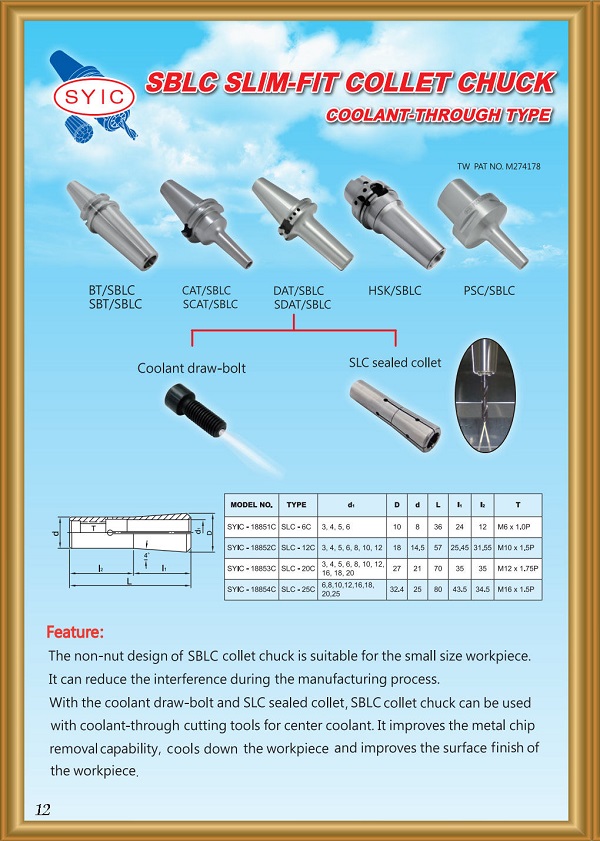

- SBLC Slim-Fit Collet Chuck(with coolant through)

SBLC Slim-Fit Collet Chuck(with coolant through)

series:

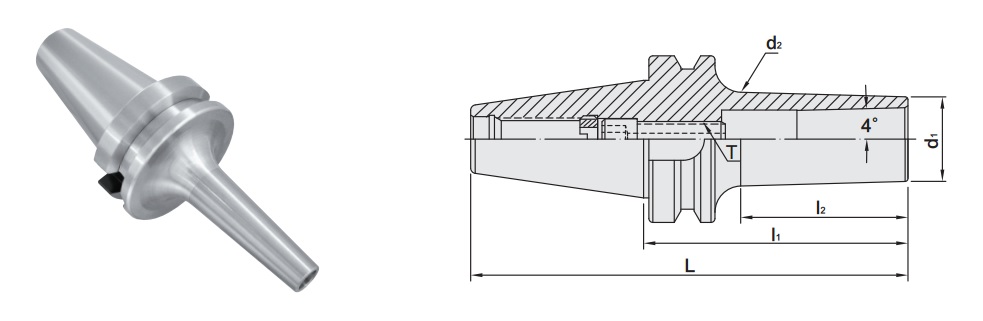

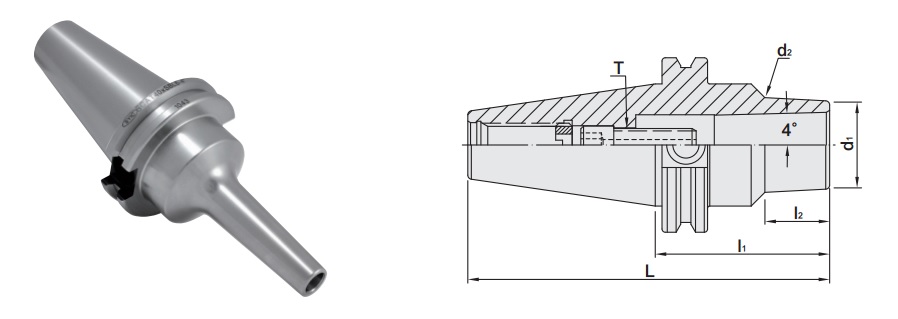

BT/SBLC SLIM-FIT COLLET CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | T | RECOMMENDED TORQUE | SIZE RANGE | WEIGHT (KGS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| N.m | Ibf-ft | ||||||||||

| 5010-623-006-070 | BT30xSBLC6-70 | 118.4 | 70 | 38 | 14 | 18.1 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1 |

| 5010-623-006-100 | BT30xSBLC6-100 | 148.4 | 100 | 68 | 14 | 21.2 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1.25 |

| 5010-623-012-070 | BT30xSBLC12-70 | 118.4 | 70 | 47 | 26 | 33.4 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.2 |

| 5010-623-012-100 | BT30xSBLC12-100 | 148.4 | 100 | 77 | 26 | 38.1 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.45 |

| 5010-623-012-130 | BT30xSBLC12-130 | 178.4 | 130 | 106 | 26 | 35.2 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.65 |

| 5010-623-020-080 | BT30xSBLC20-80 | 128.4 | 80 | 55 | 34 | 37.7 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 1.2 |

| 5010-623-020-100 | BT30xSBLC20-100 | 148.4 | 100 | 77 | 34 | 39.2 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 1.45 |

| 5011-623-006-070 | BT40xSBLC6-70 | 135.4 | 70 | 28 | 14 | 17.1 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1.2 |

| 5011-623-006-100 | BT40xSBLC6-100 | 165.4 | 100 | 58 | 14 | 20.1 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1.6 |

| 5011-623-006-130 | BT40xSBLC6-130 | 195.4 | 130 | 88 | 14 | 23.3 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1.8 |

| 5011-623-006-200 | BT40xSBLC6-200 | 265.4 | 200 | 161 | 14 | 30.9 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 2 |

| 5011-623-008-100 | BT40xSBLC8-100 | 165.4 | 100 | 58.7 | 20 | 26.1 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 1.25 |

| 5011-623-008-130 | BT40xSBLC8-130 | 195.4 | 130 | 93.5 | 20 | 29.8 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 1.38 |

| 5011-623-008-150 | BT40xSBLC8-150 | 215.4 | 150 | 113.5 | 20 | 31.8 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 1.5 |

| 5011-623-012-070 | BT40xSBLC12-70 | 135.4 | 70 | 33 | 26 | 31 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.5 |

| 5011-623-012-100 | BT40xSBLC12-100 | 165.4 | 100 | 63 | 26 | 31.6 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.7 |

| 5011-623-012-130 | BT40xSBLC12-130 | 195.4 | 130 | 93 | 26 | 34.2 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.9 |

| 5011-623-012-150 | BT40xSBLC12-150 | 215.4 | 150 | 113 | 26 | 36 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 2.1 |

| 5011-623-012-170 | BT40xSBLC12-170 | 235.4 | 170 | 133 | 26 | 37.7 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 2.3 |

| 5011-623-020-070 | BT40xSBLC20-70 | 135.4 | 70 | 33 | 35 | 38.1 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 1.5 |

| 5011-623-020-100 | BT40xSBLC20-100 | 165.4 | 100 | 68 | 35 | 41 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 1.7 |

| 5011-623-020-130 | BT40xSBLC20-130 | 195.4 | 130 | 98 | 35 | 43.6 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 1.9 |

| 5011-623-020-150 | BT40xSBLC20-150 | 215.4 | 150 | 118 | 35 | 45.3 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 2.1 |

| 5011-623-020-170 | BT40xSBLC20-170 | 235.4 | 170 | 138 | 35 | 47.1 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 2.3 |

| 5011-623-025-080 | BT40xSBLC25-80 | 145.4 | 80 | 50.1 | 40 | 44.3 | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 1.7 |

| 5011-623-025-100 | BT40xSBLC25-100 | 165.4 | 100 | 70.1 | 40 | 46.1 | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 1.9 |

| 5012-623-006-070 | BT50xSBLC6-70 | 171.8 | 70 | 17 | 14 | 15.9 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 4 |

| 5012-623-006-100 | BT50xSBLC6-100 | 201.8 | 100 | 47 | 14 | 19.1 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 4.1 |

| 5012-623-006-150 | BT50xSBLC6-150 | 251.8 | 150 | 97.7 | 14 | 24.2 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 4.3 |

| 5012-623-006-200 | BT50xSBLC6-200 | 301.8 | 200 | 147.7 | 14 | 29.4 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 4.6 |

| 5012-623-008-100 | BT50xSBLC8-100 | 201.8 | 100 | 47.7 | 20 | 25 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 3.78 |

| 5012-623-008-130 | BT50xSBLC8-130 | 231.8 | 130 | 77.7 | 20 | 28.1 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 3.92 |

| 5012-623-008-150 | BT50xSBLC8-150 | 251.8 | 150 | 97.7 | 20 | 30.2 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 4.04 |

| 5012-623-012-070 | BT50xSBLC12-70 | 171.8 | 70 | 22 | 26 | 28.1 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 4.2 |

| 5012-623-012-100 | BT50xSBLC12-100 | 201.8 | 100 | 52 | 26 | 30.6 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 4.3 |

| 5012-623-012-125 | BT50xSBLC12-125 | 226.8 | 125 | 77 | 26 | 32.9 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 4.5 |

| 5012-623-012-150 | BT50xSBLC12-150 | 251.8 | 150 | 102 | 26 | 35 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 4.8 |

| 5012-623-012-170 | BT50xSBLC12-170 | 271.8 | 170 | 122 | 26 | 36.7 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 5 |

| 5012-623-020-070 | BT50xSBLC20-70 | 171.8 | 70 | 22 | 35 | 36.9 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 4.6 |

| 5012-623-020-100 | BT50xSBLC20-100 | 201.8 | 100 | 52 | 35 | 39.6 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 4.7 |

| 5012-623-020-125 | BT50xSBLC20-125 | 226.8 | 125 | 77 | 35 | 41.8 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 4.9 |

| 5012-623-020-170 | BT50xSBLC20-170 | 271.8 | 170 | 122 | 35 | 45.6 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 5.3 |

| 5012-623-020-200 | BT50xSBLC20-200 | 301.8 | 200 | 152 | 35 | 48.3 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 5.6 |

| 5012-623-025-070 | BT50xSBLC25-70 | 171.8 | 70 | 22.4 | 40 | 41.9 | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 4.8 |

| 5012-623-025-100 | BT50xSBLC25-100 | 201.8 | 100 | 52.4 | 40 | 44.5 | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 5 |

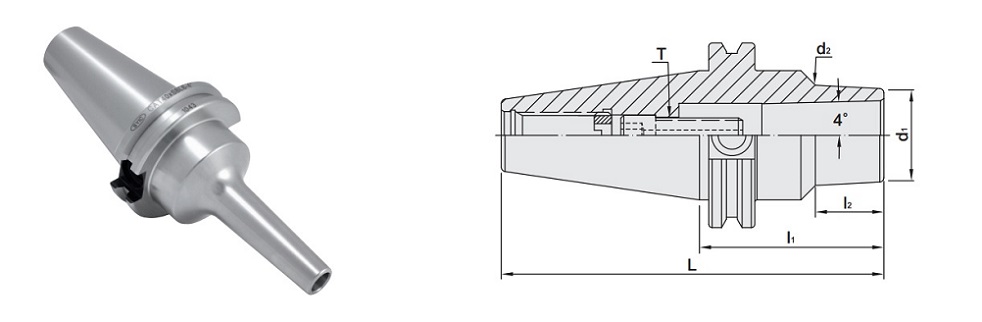

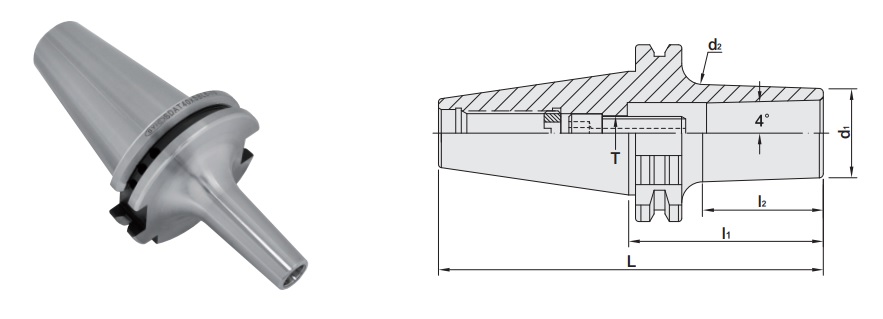

CAT/SBLC SLIM-FIT COLLET CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | T | RECOMMENDED TORQUE | SIZE RANGE | WEIGHT (KGS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| N.m | Ibf-ft | ||||||||||

| 5031-623-006-076 | CAT40xSBLC6-3" | 5.687 | 3 | 1.09 | 0.55 | 0.64 | M6 x 1.0P | 12 | 9 | 0.125 ~ 0.25 | 1 |

| 5031-623-006-102 | CAT40xSBLC6-4" | 6.687 | 4 | 2.11 | 0.55 | 0.73 | M6 x 1.0P | 12 | 9 | 0.125 ~ 0.25 | 1.25 |

| 5031-623-006-152 | CAT40xSBLC6-6" | 8.687 | 6 | 4.17 | 0.55 | 0.91 | M6 x 1.0P | 12 | 9 | 0.125 ~ 0.25 | 1.2 |

| 5031-623-008-102 | CAT40xSBLC8-4" | 6.687 | 4 | 2.18 | 0.787 | 1.02 | M8 x 1.25P | 29 | 21 | 0.125 ~ 0.3125 | 1.13 |

| 5031-623-008-127 | CAT40xSBLC8-5" | 7.687 | 5 | 3.43 | 0.787 | 1.14 | M8 x 1.25P | 29 | 21 | 0.125 ~ 0.3125 | 1.24 |

| 5031-623-008-152 | CAT40xSBLC8-6" | 8.687 | 6 | 4.43 | 0.787 | 1.25 | M8 x 1.25P | 29 | 21 | 0.125 ~ 0.3125 | 1.39 |

| 5031-623-012-064 | CAT40xSBLC12-2.5" | 5.187 | 2.5 | 0.82 | 1.02 | 1.15 | M10 x 1.5P | 45 | 33 | 0.125 ~ 0.5 | 1.45 |

| 5031-623-012-102 | CAT40xSBLC12-4" | 6.687 | 4 | 2.23 | 1.02 | 1.25 | M10 x 1.5P | 45 | 33 | 0.125 ~ 0.5 | 1.2 |

| 5031-623-012-152 | CAT40xSBLC12-6" | 8.687 | 6 | 4.49 | 1.02 | 1.49 | M10 x 1.5P | 45 | 33 | 0.125 ~ 0.5 | 1.45 |

| 5031-623-020-064 | CAT40xSBLC20-2.5" | 5.187 | 2.5 | 0.97 | 1.38 | 1.46 | M12 x 1.75P | 60 | 44 | 0.125 ~ 0.75 | 1.2 |

| 5031-623-020-102 | CAT40xSBLC20-4" | 6.687 | 4 | 2.54 | 1.37 | 1.6 | M12 x 1.75P | 60 | 44 | 0.125 ~ 0.75 | 1.6 |

| 5031-623-020-152 | CAT40xSBLC20-6" | 8.687 | 6 | 4.26 | 1.37 | - | M12 x 1.75P | 60 | 44 | 0.125 ~ 0.75 | 1.5 |

| 5031-623-025-083 | CAT40xSBLC25-3.25" | 5.937 | 3.25 | 1.86 | 1.57 | 1.73 | M16 x 2.0P | 90 | 66 | 0.125 ~ 1 | 1.4 |

| 5031-623-025-102 | CAT40xSBLC25-4" | 6.687 | 4 | 2.61 | 1.57 | 1.75 | M16 x 2.0P | 90 | 66 | 0.125 ~ 1 | 1.6 |

| 5032-623-006-089 | CAT50xSBLC6-3.5" | 7.5 | 3.5 | 1.56 | 0.55 | 0.71 | M6 x 1.0P | 12 | 9 | 0.125 ~ 0.25 | 1.7 |

| 5032-623-006-114 | CAT50xSBLC6-4.5" | 8.5 | 4.5 | 2.37 | 0.55 | 0.8 | M6 x 1.0P | 12 | 9 | 0.125 ~ 0.25 | 1.5 |

| 5032-623-006-152 | CAT50xSBLC6-6" | 10 | 6 | 3.96 | 0.55 | 0.96 | M6 x 1.0P | 12 | 9 | 0.125 ~ 0.25 | 1.7 |

| 5032-623-008-102 | CAT50xSBLC8-4" | 8 | 4 | 2.24 | 0.787 | 1.01 | M8 x 1.25P | 29 | 21 | 0.125 ~ 0.3125 | 3.23 |

| 5032-623-008-127 | CAT50xSBLC8-5" | 9 | 5 | 3.25 | 0.787 | 1.12 | M8 x 1.25P | 29 | 21 | 0.125 ~ 0.3125 | 3.36 |

| 5032-623-008-152 | CAT50xSBLC8-6" | 10 | 6 | 4.24 | 0.787 | 1.23 | M8 x 1.25P | 29 | 21 | 0.125 ~ 0.3125 | 3.51 |

| 5032-623-012-064 | CAT50xSBLC12-2.5" | 6.5 | 2.5 | 0.93 | 1.02 | 1.11 | M10 x 1.5P | 45 | 33 | 0.125 ~ 0.5 | 4 |

| 5032-623-012-114 | CAT50xSBLC12-4.5" | 8.5 | 4.5 | 2.74 | 1.02 | 1.26 | M10 x 1.5P | 45 | 33 | 0.125 ~ 0.5 | 4.1 |

| 5032-623-012-152 | CAT50xSBLC12-6" | 10 | 6 | 4.24 | 1.02 | 1.39 | M10 x 1.5P | 45 | 33 | 0.125 ~ 0.5 | 4.2 |

| 5032-623-020-064 | CAT50xSBLC20-2.5" | 6.5 | 2.5 | 0.74 | 1.37 | 1.44 | M12 x 1.75P | 60 | 44 | 0.125 ~ 0.75 | 4.3 |

| 5032-623-020-114 | CAT50xSBLC20-4.5" | 8.5 | 4.5 | 2.74 | 1.37 | 1.61 | M12 x 1.75P | 60 | 44 | 0.125 ~ 0.75 | 4.6 |

| 5032-623-020-152 | CAT50xSBLC20-6" | 10 | 6 | 4.11 | 1.37 | 1.73 | M12 x 1.75P | 60 | 44 | 0.125 ~ 0.75 | 4.7 |

| 5032-623-025-070 | CAT50xSBLC25-2.75" | 6.75 | 2.75 | 1.33 | 1.57 | 1.69 | M16 x 2.0P | 90 | 66 | 0.125 ~ 1 | 4.4 |

| 5032-623-025-114 | CAT50xSBLC25-4.5" | 8.5 | 4.5 | 3.06 | 1.57 | 1.84 | M16 x 2.0P | 90 | 66 | 0.125 ~ 1 | 4.6 |

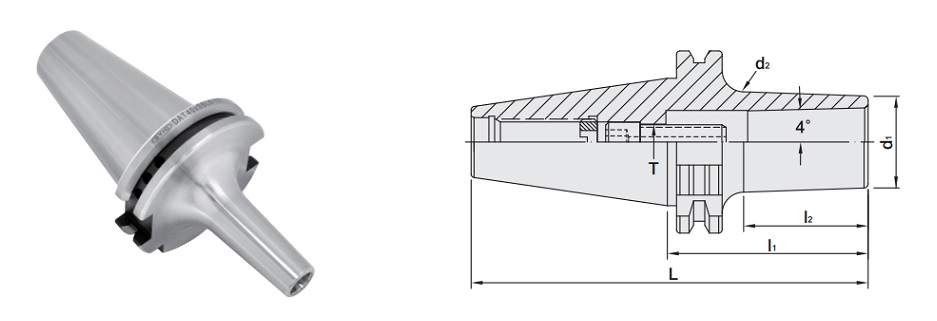

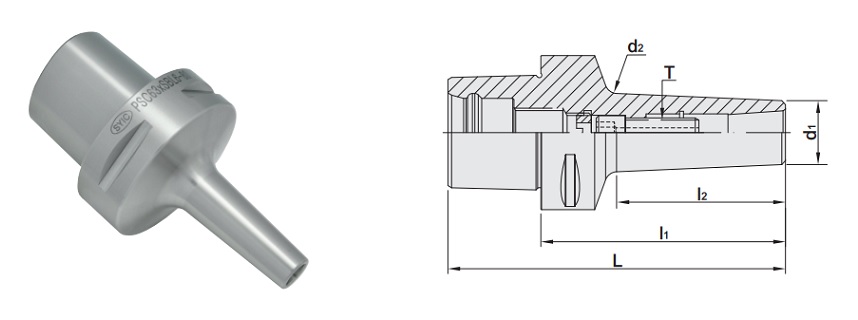

DAT/SBLC SLIM-FIT COLLET CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | T | RECOMMENDED TORQUE | SIZE RANGE | WEIGHT (KGS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| N.m | Ibf-ft | ||||||||||

| 5050-623-006-070 | DAT30xSBLC6-70 | 117.8 | 70 | 41 | 14 | 18 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 0.39 |

| 5050-623-006-100 | DAT30xSBLC6-100 | 147.8 | 100 | 71 | 14 | 21 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 0.4 |

| 5050-623-012-070 | DAT30xSBLC12-70 | 117.8 | 70 | 48 | 26 | 31 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 0.42 |

| 5050-623-012-100 | DAT30xSBLC12-100 | 147.8 | 100 | 78 | 26 | 34 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 0.43 |

| 5050-623-020-080 | DAT30xSBLC20-80 | 127.8 | 80 | 58 | 34 | 38 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 0.44 |

| 5050-623-020-100 | DAT30xSBLC20-100 | 147.8 | 100 | 79 | 34 | 39 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 0.45 |

| 5051-623-006-070 | DAT40xSBLC6-70 | 138.4 | 70 | 36 | 14 | 17 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1 |

| 5051-623-006-100 | DAT40xSBLC6-100 | 168.4 | 100 | 58 | 14 | 20 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1.1 |

| 5051-623-008-100 | DAT40xSBLC8-100 | 168.4 | 100 | 71.4 | 20 | 27.4 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 1.25 |

| 5051-623-008-130 | DAT40xSBLC8-130 | 198.4 | 130 | 101.4 | 20 | 30.6 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 1.19 |

| 5051-623-008-150 | DAT40xSBLC8-150 | 218.4 | 150 | 121.4 | 20 | 32.6 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 1.32 |

| 5051-623-012-070 | DAT40xSBLC12-70 | 138.4 | 70 | 41 | 26 | 29 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.2 |

| 5051-623-012-100 | DAT40xSBLC12-100 | 168.4 | 100 | 71 | 26 | 32 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.3 |

| 5051-623-012-170 | DAT40xSBLC12-170 | 238.4 | 170 | 146 | 26 | 38 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 2 |

| 5051-623-020-070 | DAT40xSBLC20-70 | 138.4 | 70 | 41 | 35 | 38 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 1.3 |

| 5051-623-020-100 | DAT40xSBLC20-100 | 168.4 | 100 | 78 | 35 | 41 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 1.4 |

| 5051-623-025-080 | DAT40xSBLC25-80 | 148.4 | 80 | 58 | 40 | 45 | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 1.5 |

| 5051-623-025-100 | DAT40xSBLC25-100 | 168.4 | 100 | 79 | 40 | 46 | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 1.6 |

| 5052-623-006-070 | DAT50xSBLC6-70 | 171.75 | 70 | 36 | 14 | 17 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 2.8 |

| 5052-623-006-100 | DAT50xSBLC6-100 | 201.75 | 100 | 66 | 14 | 20 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 2.9 |

| 5052-623-008-100 | DAT50xSBLC8-100 | 201.75 | 100 | 71.4 | 20 | 27.4 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 2.81 |

| 5052-623-008-130 | DAT50xSBLC8-130 | 231.75 | 130 | 101.4 | 20 | 30.6 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 2.98 |

| 5052-623-008-150 | DAT50xSBLC8-150 | 251.75 | 150 | 121.4 | 20 | 32.7 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 3.11 |

| 5052-623-012-070 | DAT50xSBLC12-70 | 171.75 | 70 | 41 | 26 | 29 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 3 |

| 5052-623-012-100 | DAT50xSBLC12-100 | 201.75 | 100 | 71 | 26 | 32 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 3.1 |

| 5052-623-020-070 | DAT50xSBLC20-70 | 171.75 | 70 | 41 | 35 | 38 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 3.2 |

| 5052-623-020-100 | DAT50xSBLC20-100 | 201.75 | 100 | 71 | 35 | 41 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 3.3 |

| 5052-623-020-170 | DAT50xSBLC20-170 | 271.75 | 170 | 139 | 35 | 47 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 3.9 |

| 5052-623-025-070 | DAT50xSBLC25-70 | 171.75 | 70 | 39 | 40 | 43 | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 3.2 |

| 5052-623-025-100 | DAT50xSBLC25-100 | 201.75 | 100 | 71 | 40 | 46 | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 3.4 |

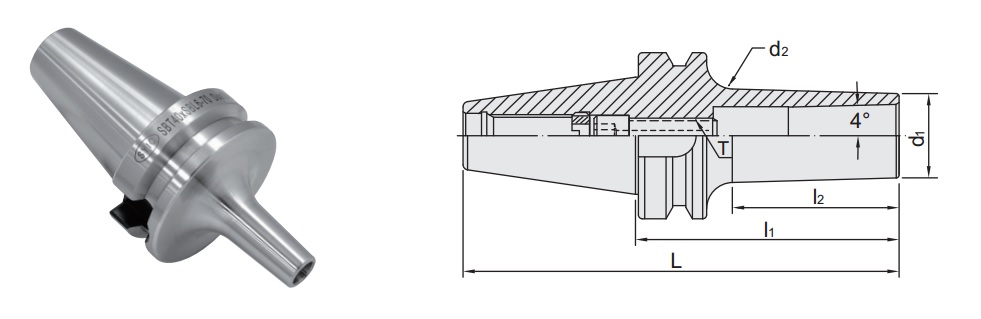

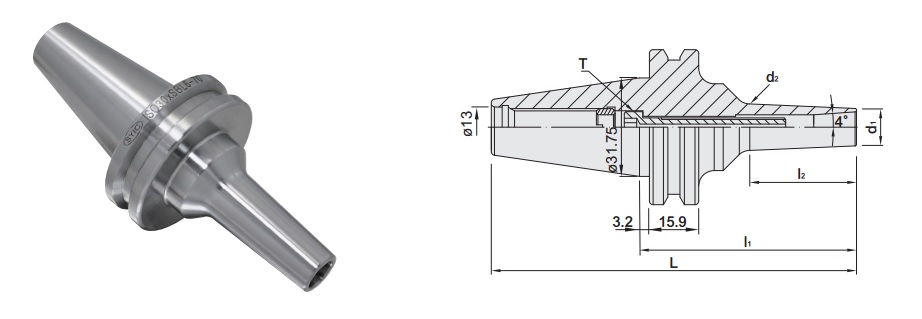

DualDRIVE+ SBT/SBLC SLIM-FIT COLLET CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | T | RECOMMENDED TORQUE | SIZE RANGE | WEIGHT (KGS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| N.m | Ibf-ft | ||||||||||

| 5025-623-006-070 | SBT30xSBLC6-70 | 118.4 | 70 | 38 | 14 | 18 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 0.60 |

| 5025-623-006-100 | SBT30xSBLC6-100 | 148.4 | 100 | 68 | 14 | 21 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1.25 |

| 5025-623-012-070 | SBT30xSBLC12-70 | 118.4 | 70 | 47 | 26 | 33 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.20 |

| 5025-623-012-100 | SBT30xSBLC12-100 | 148.4 | 100 | 77 | 26 | 38 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.45 |

| 5025-623-020-080 | SBT30xSBLC20-80 | 128.4 | 80 | 55 | 34 | 37 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 1.20 |

| 5025-623-020-100 | SBT30xSBLC20-100 | 148.4 | 100 | 77 | 34 | 39 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 1.45 |

| 5026-623-006-070 | SBT40xSBLC6-70 | 135.4 | 70 | 28 | 14 | 17 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1.07 |

| 5026-623-006-100 | SBT40xSBLC6-100 | 165.4 | 100 | 58 | 14 | 20 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1.14 |

| 5026-623-006-130 | SBT40xSBLC6-130 | 195.4 | 130 | 88 | 14 | 23 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1.23 |

| 5026-623-008-100 | SBT40xSBLC8-100 | 165.4 | 100 | 58.7 | 20 | 26.1 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 1.25 |

| 5026-623-008-130 | SBT40xSBLC8-130 | 195.4 | 130 | 93.5 | 20 | 29.8 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 1.38 |

| 5026-623-008-150 | SBT40xSBLC8-150 | 215.4 | 150 | 113.5 | 20 | 31.8 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 1.50 |

| 5026-623-012-070 | SBT40xSBLC12-70 | 135.4 | 70 | 33 | 26 | 31 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.14 |

| 5026-623-012-100 | SBT40xSBLC12-100 | 165.4 | 100 | 63 | 26 | 31 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.29 |

| 5026-623-012-130 | SBT40xSBLC12-130 | 195.4 | 130 | 93 | 26 | 34 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.47 |

| 5026-623-012-170 | SBT40xSBLC12-170 | 235.4 | 170 | 133 | 26 | 37 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.76 |

| 5026-623-012-200 | SBT40xSBLC12-200 | 265.4 | 200 | 168 | 26 | 40 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.92 |

| 5026-623-020-070 | SBT40xSBLC20-70 | 135.4 | 70 | 33 | 35 | 38 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 1.50 |

| 5026-623-020-100 | SBT40xSBLC20-100 | 165.4 | 100 | 68 | 35 | 40 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 1.70 |

| 5026-623-020-130 | SBT40xSBLC20-130 | 195.4 | 130 | 98 | 35 | 43 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 1.74 |

| 5026-623-025-080 | SBT40xSBLC25-80 | 145.4 | 80 | 50.1 | 40 | 44.3 | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 1.70 |

| 5026-623-025-100 | SBT40xSBLC25-100 | 165.4 | 100 | 70.1 | 40 | 46.1 | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 1.90 |

| 5027-623-006-070 | SBT50xSBLC6-70 | 171.8 | 70 | 17 | 14 | 15 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 4.00 |

| 5027-623-006-100 | SBT50xSBLC6-100 | 201.8 | 100 | 47 | 14 | 19 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 4.10 |

| 5027-623-008-100 | SBT50xSBLC8-100 | 201.8 | 100 | 47.7 | 20 | 25 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 3.78 |

| 5027-623-008-130 | SBT50xSBLC8-130 | 231.8 | 130 | 77.7 | 20 | 28.1 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 3.92 |

| 5027-623-008-150 | SBT50xSBLC8-150 | 251.8 | 150 | 97.7 | 20 | 30.2 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 4.04 |

| 5027-623-012-070 | SBT50xSBLC12-70 | 171.8 | 70 | 22 | 26 | 28 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 4.20 |

| 5027-623-012-100 | SBT50xSBLC12-100 | 201.8 | 100 | 52 | 26 | 30 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 4.30 |

| 5027-623-012-125 | SBT50xSBLC12-125 | 226.8 | 125 | 77 | 26 | 32 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 4.40 |

| 5027-623-020-070 | SBT50xSBLC20-70 | 171.8 | 70 | 22 | 35 | 36 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 4.60 |

| 5027-623-020-100 | SBT50xSBLC20-100 | 201.8 | 100 | 52 | 35 | 39 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 4.70 |

| 5027-623-020-125 | SBT50xSBLC20-125 | 226.8 | 125 | 77 | 35 | 41 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 4.22 |

| 5027-623-025-070 | SBT50xSBLC25-70 | 171.8 | 70 | 22.4 | 40 | 41.9 | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 4.80 |

| 5027-623-025-100 | SBT50xSBLC25-100 | 201.8 | 100 | 52.4 | 40 | 44.5 | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 5.00 |

DualDRIVE+ SCAT/SBLC SLIM-FIT COLLET CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | T | RECOMMENDED TORQUE | SIZE RANGE | WEIGHT (KGS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| N.m | Ibf-ft | ||||||||||

| 5043-623-006-076 | SCAT40xSBLC6-3" | 5.687 | 3 | 1.09 | 0.55 | 0.65 | M6 x 1.0P | 12 | 9 | 0.125 ~ 0.25 | 1.00 |

| 5043-623-006-102 | SCAT40xSBLC6-4" | 6.687 | 4 | 2.12 | 0.55 | 0.74 | M6 x 1.0P | 12 | 9 | 0.125 ~ 0.25 | 1.25 |

| 5043-623-006-152 | SCAT40xSBLC6-6" | 8.687 | 6 | 4.17 | 0.55 | 0.92 | M6 x 1.0P | 12 | 9 | 0.125 ~ 0.25 | 1.20 |

| 5043-623-008-102 | SCAT40xSBLC8-4" | 6.687 | 4 | 2.18 | 0.787 | 1.02 | M8 x 1.25P | 29 | 21 | 0.125 ~ 0.3125 | 1.13 |

| 5043-623-008-127 | SCAT40xSBLC8-5" | 7.687 | 5 | 3.43 | 0.787 | 1.14 | M8 x 1.25P | 29 | 21 | 0.125 ~ 0.3125 | 1.24 |

| 5043-623-008-152 | SCAT40xSBLC8-6" | 8.687 | 6 | 4.43 | 0.787 | 1.25 | M8 x 1.25P | 29 | 21 | 0.125 ~ 0.3125 | 1.39 |

| 5043-623-012-064 | SCAT40xSBLC12-2.5" | 5.187 | 2.5 | 0.82 | 1.02 | 1.15 | M10 x 1.5P | 45 | 33 | 0.125 ~ 0.5 | 1.45 |

| 5043-623-012-102 | SCAT40xSBLC12-4" | 6.687 | 4 | 2.23 | 1.02 | 1.26 | M10 x 1.5P | 45 | 33 | 0.125 ~ 0.5 | 1.20 |

| 5043-623-012-152 | SCAT40xSBLC12-6" | 8.687 | 6 | 4.49 | 1.02 | 1.49 | M10 x 1.5P | 45 | 33 | 0.125 ~ 0.5 | 1.45 |

| 5043-623-020-064 | SCAT40xSBLC20-2.5" | 5.187 | 2.5 | 0.98 | 1.38 | 1.46 | M12 x 1.75P | 60 | 44 | 0.125 ~ 0.75 | 1.20 |

| 5043-623-020-102 | SCAT40xSBLC20-4" | 6.687 | 4 | 2.55 | 1.37 | 1.6 | M12 x 1.75P | 60 | 44 | 0.125 ~ 0.75 | 1.60 |

| 5043-623-020-152 | SCAT40xSBLC20-6" | 8.687 | 6 | 4.62 | 1.37 | - | M12 x 1.75P | 60 | 44 | 0.125 ~ 0.75 | 1.50 |

| 5043-623-025-083 | SCAT40xSBLC25-3.25" | 5.937 | 3.25 | 1.86 | 1.57 | 1.73 | M16 x 1.5P | 90 | 66 | 0.125 ~ 1 | 1.40 |

| 5043-623-025-102 | SCAT40xSBLC25-4" | 6.687 | 4 | 2.61 | 1.57 | 1.75 | M16 x 1.5P | 90 | 66 | 0.125 ~ 1 | 1.60 |

| 5044-623-006-089 | SCAT50xSBLC6-3.5" | 7.5 | 3.5 | 1.56 | 0.55 | 0.71 | M6 x 1.0P | 12 | 9 | 0.125 ~ 0.25 | 1.70 |

| 5044-623-006-114 | SCAT50xSBLC6-4.5" | 8.5 | 4.5 | 2.38 | 0.55 | 0.8 | M6 x 1.0P | 12 | 9 | 0.125 ~ 0.25 | 1.50 |

| 5044-623-006-152 | SCAT50xSBLC6-6" | 10 | 6 | 3.96 | 0.55 | 0.97 | M6 x 1.0P | 12 | 9 | 0.125 ~ 0.25 | 1.70 |

| 5044-623-008-102 | SCAT50xSBLC8-4" | 8 | 4 | 2.24 | 0.787 | 1.01 | M8 x 1.25P | 29 | 21 | 0.125 ~ 0.3125 | 3.23 |

| 5044-623-008-127 | SCAT50xSBLC8-5" | 9 | 5 | 3.25 | 0.787 | 1.12 | M8 x 1.25P | 29 | 21 | 0.125 ~ 0.3125 | 3.36 |

| 5044-623-008-152 | SCAT50xSBLC8-6" | 10 | 6 | 4.24 | 0.787 | 1.23 | M8 x 1.25P | 29 | 21 | 0.125 ~ 0.3125 | 3.51 |

| 5044-623-012-064 | SCAT50xSBLC12-2.5" | 6.5 | 2.5 | 0.93 | 1.02 | 1.11 | M10 x 1.5P | 45 | 33 | 0.125 ~ 0.5 | 4.00 |

| 5044-623-012-114 | SCAT50xSBLC12-4.5" | 8.5 | 4.5 | 2.75 | 1.02 | 1.27 | M10 x 1.5P | 45 | 33 | 0.125 ~ 0.5 | 4.10 |

| 5044-623-012-152 | SCAT50xSBLC12-6" | 10 | 6 | 4.25 | 1.02 | 1.4 | M10 x 1.5P | 45 | 33 | 0.125 ~ 0.5 | 4.20 |

| 5044-623-020-064 | SCAT50xSBLC20-2.5" | 6.5 | 2.5 | 0.75 | 1.37 | 1.44 | M12 x 1.75P | 60 | 44 | 0.125 ~ 0.75 | 4.30 |

| 5044-623-020-114 | SCAT50xSBLC20-4.5" | 8.5 | 4.5 | 2.75 | 1.37 | 1.62 | M12 x 1.75P | 60 | 44 | 0.125 ~ 0.75 | 4.60 |

| 5044-623-020-152 | SCAT50xSBLC20-6" | 10 | 6 | 4.12 | 1.37 | 1.74 | M12 x 1.75P | 60 | 44 | 0.125 ~ 0.75 | 4.70 |

| 5044-623-025-070 | SCAT50xSBLC25-2.75" | 6.75 | 2.75 | 1.33 | 1.57 | 1.69 | M16 x 1.5P | 90 | 66 | 0.125 ~ 1 | 4.40 |

| 5044-623-025-114 | SCAT50xSBLC25-4.5" | 8.5 | 4.5 | 3.06 | 1.57 | 1.84 | M16 x 1.5P | 90 | 66 | 0.125 ~ 1 | 4.60 |

DualDRIVE+ SDAT/SBLC SLIM-FIT COLLET CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | T | RECOMMENDED TORQUE | SIZE RANGE | WEIGHT (KGS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| N.m | Ibf-ft | ||||||||||

| 5066-623-006-070 | SDAT40xSBLC6-70 | 138.4 | 70 | 36 | 14 | 17 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1.00 |

| 5066-623-006-100 | SDAT40xSBLC6-100 | 168.4 | 100 | 58 | 14 | 20 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1.10 |

| 5066-623-008-100 | SDAT40xSBLC8-100 | 168.4 | 100 | 71.4 | 20 | 27.4 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 1.25 |

| 5066-623-008-130 | SDAT40xSBLC8-130 | 198.4 | 130 | 101.4 | 20 | 30.6 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 1.19 |

| 5066-623-008-150 | SDAT40xSBLC8-150 | 218.4 | 150 | 121.4 | 20 | 32.6 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 1.32 |

| 5066-623-012-070 | SDAT40xSBLC12-70 | 138.4 | 70 | 41 | 26 | 29 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.20 |

| 5066-623-012-100 | SDAT40xSBLC12-100 | 168.4 | 100 | 73 | 26 | 32 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.30 |

| 5066-623-020-070 | SDAT40xSBLC20-70 | 138.4 | 70 | 46 | 35 | 39 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 1.30 |

| 5066-623-020-100 | SDAT40xSBLC20-100 | 168.4 | 100 | 78 | 35 | 41 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 1.40 |

| 5066-623-025-080 | SDAT40xSBLC25-80 | 148.4 | 80 | 58 | 40 | 45 | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 1.50 |

| 5066-623-025-100 | SDAT40xSBLC25-100 | 168.4 | 100 | 79 | 40 | 46 | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 1.60 |

| 5067-623-006-070 | SDAT50xSBLC6-70 | 171.75 | 70 | 36 | 14 | 17 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 2.80 |

| 5067-623-006-100 | SDAT50xSBLC6-100 | 201.75 | 100 | 66 | 14 | 20 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 2.90 |

| 5067-623-008-100 | SDAT50xSBLC8-100 | 201.75 | 100 | 71.4 | 20 | 27.4 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 2.81 |

| 5067-623-008-130 | SDAT50xSBLC8-130 | 231.75 | 130 | 101.4 | 20 | 30.6 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 2.98 |

| 5067-623-008-150 | SDAT50xSBLC8-150 | 251.75 | 150 | 121.4 | 20 | 32.7 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 3.11 |

| 5067-623-012-070 | SDAT50xSBLC12-70 | 171.75 | 70 | 41 | 26 | 29 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 3.00 |

| 5067-623-012-100 | SDAT50xSBLC12-100 | 201.75 | 100 | 73 | 26 | 32 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 3.10 |

| 5067-623-020-070 | SDAT50xSBLC20-70 | 171.75 | 70 | 41 | 35 | 38 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 3.20 |

| 5067-623-020-100 | SDAT50xSBLC20-100 | 201.75 | 100 | 76 | 35 | 41 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 3.30 |

| 5067-623-025-080 | SDAT50xSBLC25-80 | 181.75 | 80 | 58 | 40 | 45 | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 3.20 |

| 5067-623-025-100 | SDAT50xSBLC25-100 | 201.75 | 100 | 78 | 40 | 46 | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 3.40 |

HSK/SBLC SLIM-FIT COLLET CHUCK

_figure.jpg)

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | d3 | T | RECOMMENDED TORQUE | SIZE RANGE | WEIGHT (KGS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N.m | Ibf-ft | |||||||||||

| 5072-623-006-080 | HSK50AxSBLC6-80 | 105 | 80 | 44 | 14 | 18 | - | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1.40 |

| 5072-623-006-120 | HSK50AxSBLC6-120 | 145 | 120 | 84 | 14 | 22 | - | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1.50 |

| 5072-623-012-110 | HSK50AxSBLC12-110 | 135 | 110 | 65 | 26 | 42 | 36 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.50 |

| 5072-623-012-130 | HSK50AxSBLC12-130 | 155 | 130 | 86 | 26 | 42 | 39 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.85 |

| 5072-623-020-120 | HSK50AxSBLC20-120 | 145 | 120 | 93 | 35 | 42 | - | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 1.80 |

| 5072-623-020-150 | HSK50AxSBLC20-150 | 175 | 150 | 123 | 35 | 42 | - | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 2.00 |

| 5073-623-006-080 | HSK63AxSBLC6-80 | 112 | 80 | 39 | 14 | 18 | - | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1.70 |

| 5073-623-006-120 | HSK63AxSBLC6-120 | 152 | 120 | 79 | 14 | 22 | - | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1.90 |

| 5073-623-008-130 | HSK63AxSBLC8-130 | 162 | 130 | 94 | 20 | 29 | - | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 0.99 |

| 5073-623-008-150 | HSK63AxSBLC8-150 | 182 | 150 | 114 | 20 | 32 | - | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 1.11 |

| 5073-623-012-110 | HSK63AxSBLC12-110 | 142 | 110 | 79 | 26 | 37 | - | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.80 |

| 5073-623-012-150 | HSK63AxSBLC12-150 | 182 | 150 | 119 | 26 | 42 | - | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 2.00 |

| 5073-623-020-120 | HSK63AxSBLC20-120 | 152 | 120 | 89 | 35 | 42 | - | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 2.00 |

| 5073-623-020-140 | HSK63AxSBLC20-140 | 172 | 140 | 97 | 35 | 45 | 43 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 2.45 |

| 5075-623-006-120 | HSK100AxSBLC6-120 | 170 | 120 | 76 | 14 | 22 | - | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 2.15 |

| 5075-623-008-130 | HSK100AxSBLC8-130 | 180 | 130 | 86 | 20 | 29 | - | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 2.31 |

| 5075-623-008-150 | HSK100AxSBLC8-150 | 200 | 150 | 106 | 20 | 31 | - | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 2.43 |

| 5075-623-012-120 | HSK100AxSBLC12-120 | 170 | 120 | 81 | 26 | 37 | - | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 2.40 |

| 5075-623-020-135 | HSK100AxSBLC20-135 | 185 | 135 | 88 | 35 | 45 | 42 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 2.74 |

| 5075-623-025-150 | HSK100AxSBLC25-150 | 200 | 150 | 111 | 40 | 49 | - | M16 x 1.5P | 90 | 66 | 6 ~ 25.4 | 2.80 |

PSC/SBLC SLIM-FIT COLLET CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | T | RECOMMENDED TORQUE | SIZE RANGE | WEIGHT (KGS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| N.m | Ibf-ft | ||||||||||

| 5140-623-006-075 | PSC32xSBLC6-75 | 94 | 75 | 58 | 14 | 20.1 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 0.50 |

| 5140-623-012-090 | PSC32xSBLC12-90 | 109 | 90 | 74 | 26 | 31.2 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 0.70 |

| 5141-623-006-075 | PSC40xSBLC6-75 | 99 | 75 | 43 | 14 | 18.5 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 0.60 |

| 5141-623-012-090 | PSC40xSBLC12-90 | 114 | 90 | 68 | 26 | 31.9 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 0.70 |

| 5141-623-020-105 | PSC40xSBLC20-105 | 129 | 105 | 57 | 35 | 40 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 0.80 |

| 5142-623-006-080 | PSC50xSBLC6-80 | 110 | 80 | 45 | 14 | 18.8 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 0.60 |

| 5142-623-008-100 | PSC50xSBLC8-100 | 130 | 100 | 70.5 | 20 | 27.3 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 0.65 |

| 5142-623-012-105 | PSC50xSBLC12-105 | 135 | 105 | 80 | 26 | 33 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 0.70 |

| 5142-623-020-115 | PSC50xSBLC20-115 | 145 | 115 | 94 | 35 | 43.2 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 0.80 |

| 5143-623-006-080 | PSC63xSBLC6-80 | 118 | 80 | 43 | 14 | 18.5 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 1.00 |

| 5143-623-008-100 | PSC63xSBLC8-100 | 138 | 100 | 68.5 | 20 | 27.1 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 0.98 |

| 5143-623-012-100 | PSC63xSBLC12-100 | 138 | 100 | 69 | 26 | 32 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 1.20 |

| 5143-623-020-120 | PSC63xSBLC20-120 | 158 | 120 | 91 | 35 | 42.9 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 1.40 |

| 5144-623-006-080 | PSC80xSBLC6-80 | 128 | 80 | 40.5 | 14 | 18.2 | M6 x 1.0P | 12 | 9 | 3 ~ 6 | 2.10 |

| 5144-623-008-100 | PSC80xSBLC8-100 | 148 | 100 | 60.5 | 20 | 26.3 | M8 x 1.25P | 29 | 21 | 3 ~ 8 | 1.90 |

| 5144-623-012-100 | PSC80xSBLC12-100 | 148 | 100 | 31.2 | 26 | 60.4 | M10 x 1.5P | 45 | 33 | 3 ~ 12 | 2.40 |

| 5144-623-020-120 | PSC80xSBLC20-120 | 168 | 120 | 42 | 35 | 80.4 | M12 x 1.75P | 60 | 44 | 3 ~ 20 | 2.60 |

ISO/SBLC SLIM-FIT COLLET CHUCK

| MODEL NO. | TYPE | L | l1 | l2 | d1 | d2 | T | RECOMMENDED TORQUE | SIZE RANGE | WEIGHT (KGS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| N.m | Ibf-ft | ||||||||||

| 5113-623-006-070 | ISO30xSBLC6-70 | 117.8 | 70 | 39 | 14 | 18 | M6 | 12 | 9 | 3 ~ 6 | 0.70 |

| 5113-623-012-070 | ISO30xSBLC12-70 | 117.8 | 70 | 46 | 26 | 30 | M10 | 45 | 33 | 3 ~ 12 | 0.80 |

| 5113-623-020-080 | ISO30xSBLC20-80 | 127.8 | 80 | 58 | 35 | 37 | M12 | 60 | 44 | 3 ~ 20 | 0.85 |

series:

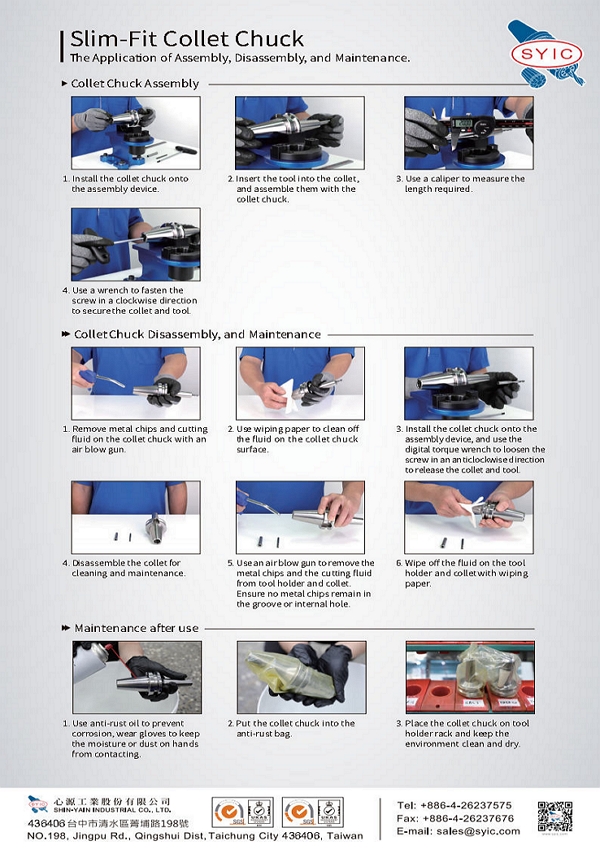

The Installation and Coolant Application of SBLC Slim-Fit Collet Chuck

Back

Back